Silicon-carbon anode battery, a new star in batteries, can it start a new revolution in batteries?

In this regard, a securities firm strongly recommended that we should pay attention to silicon carbon anodes now.

From the perspective of industrial background: In 2023, the focus of the industrial chain will be on cost reduction. In 2024, the focus will gradually shift from "cost reduction" to "efficiency enhancement." High-density batteries are equipped with silicon carbon anodes as standard, and high-performance batteries continue to advance and consolidate their position as the world's leading battery cell.

From the perspective of application necessity, the specific heat capacity of existing graphite materials can reach 365mAh/g, which is close to the upper limit of 372mAh/g. The theoretical specific heat capacity of silicon materials is more than 4000mAh/g, and the energy density of single cells can reach 843Wh/kg.

From the industrial chain process level: In 23-24, the leading silicon-carbon anode factory represented by Tianmu Pioneer has solved bottleneck problems such as expansion rate, and industrialization has gradually progressed.

Silicon-based negative electrode route

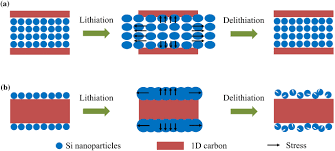

To alleviate the expansion problem, silicon materials are generally compounded with graphite during industrialization. According to the source of silicon, they are divided into two technical routes: silicon-carbon anode and silicon-oxygen anode.

Among them, the silicon-carbon negative electrode uses nano-silicon and matrix materials to form the precursor, while the silicon-oxygen negative electrode uses silicone oxide to form the precursor.

From a performance perspective, the silicon-carbon anode has a higher specific capacity and first efficiency, but its cycle performance is weak due to expansion problems; the volume expansion of silicon oxide during the lithium intercalation process is small, so the silicon-oxygen anode has better Cycle performance, but lower specific capacity and first coulombic efficiency.

According to the product parameters of the silicon-based anode on Beterui's official website, the current specific capacity of silicon-carbon anodes and silicon-oxygen anodes is between 450 and 1600mAh/g, which is significantly higher than that of graphite materials.

The difference in the silicon-based anode process is mainly concentrated in the front-end process-the processing of silicon materials. The core of silicon carbon is the preparation of nano-silica powder, and the core of silicon-oxygen is the preparation of silicon oxide.

The process selection for silicon-based negative electrodes varies depending on the process of preparing the precursor, but the back-end process is roughly the same. All require crushing, classification, surface treatment, sintering, screening, demagnetization, and other processes to obtain the final product.

The core difficulty in the silicon-carbon anode production process lies in the preparation of nano-silica powder.

The core of the silicon-oxygen anode is the preparation of SiOx (silicon oxide). Most companies synthesize SiOx from pure silicon and SiO2 to form a silicon-oxygen anode precursor, which is then prepared.

SiOx can also be purchased directly, but it still needs to be processed before it can be combined with artificial graphite to prepare a silicon-oxygen anode.

Preparation method of nano silicon powder

At present, the main preparation methods for nano-silica powder include mechanical ball milling, chemical vapor deposition, and plasma evaporation and condensation. Among them, the mechanical ball milling method has low production efficiency and is not suitable for large-scale industrial production. Chemical vapor deposition and plasma evaporation and condensation technologies The barriers are higher.

Chemical vapor precipitation (CVD) is a technology that uses silane (SiH4) as the reaction raw material to produce nano-silica powder. PECVD and LICVD are currently the most important industrial production technologies for this.

The domestic CVD representative company adopts the self-developed thermal CVD decomposition method of silane to prepare high-purity silicon powder with a particle size between 20 and 100nm.

Plasma evaporation and condensation method (PVD): This safe and efficient method has been used to manufacture high-purity, ultra-fine, spherical, and high-value-added powders in the past 10 years.

Competition landscape and market space

Nano-silica powder is a key material for improving the performance of silicon-based anodes. It is expected that as the penetration rate of large cylindrical batteries and silicon-based anodes continues to increase, the market space for nano-silica powder is expected to continue to grow.

A brokerage predicts that the global demand for nano-silica powder for silicon-based negative electrodes is expected to reach 3,786 tons in 2023, corresponding to a market space of 3.79 billion yuan. By 2025, the demand for nano-silica powder is expected to reach 24,000 tons, corresponding to a market space of 16.72 billion yuan, 2023-2025. The annual market space CAGR is 110.1%.

From the perspective of the competitive landscape, the lithium battery anode material industry is highly concentrated, mainly concentrated in China. Silicon-based anodes are an important direction for the next generation of anode materials and have become a hot spot in the industry. Mainstream lithium battery anode companies have increased their silicon-based anode production capacity, and some have achieved batch shipments.

Supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for silicon powder for battery li-ion anode, click on the needed products and send us an inquiry: sales@graphite-corp.com