Key issues about super-fast charging of lithium-ion power batteries

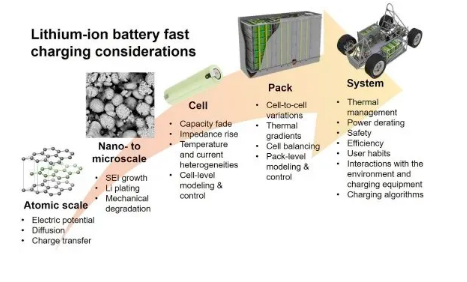

In recent years, the prevalent use of lithium-ion batteries in pure electrical cars has actually been sped up in an initiative to restrict the impacts of climate change and air contamination. However, compared to conventional gas automobiles, concerns such as range anxiousness and lengthy billing time have ended up being major issues impeding the advancement of electrical lorries. As a result, improving fast billing capabilities has become an ideal advancement objective for battery makers and automobile producers. However, research shows that reduced temperature levels and high-rate billing will create sped-up destruction of battery capacity and output power. On the other hand, the large amount of warmth produced by the battery throughout billing is difficult to dissipate uniformly and successfully, which will likewise trigger increased degradation and other safety concerns. Concern. Figure 1 reveals the aspects that affect the fast charging of lithium-ion batteries from the atomic level to the vehicle system degree. The classification of electrical car charging includes air conditioning and DC, with DC billing being much faster.

Figure1: Factors affecting fast charging of lithium-ion batteries at different levels

The principle of quick battery billing

An excellent battery should display long life and high power thickness to make it possible to charge and reenergize at any place and at any temperature level to fulfill the long-distance driving needs of electric automobiles. Nevertheless, there is a trade-off relationship between these physical residential or commercial properties and the impact of the temperature of the product and tool figures out the battery use limit. As temperature levels decline, both the charging rate and optimum voltage should be lowered to ensure security, making temperature level an essential restricting element for rapid charging. Among them, as the temperature reduces, the risk of lithium precipitation will increase substantially. Although numerous scientists have mentioned that lithium rainfall frequently occurs at temperatures below 25 ° C, it can also quickly happen at heat, particularly when the billing price and energy density are high. Furthermore, rapid billing effectiveness is likewise very closely related to temperature. The billing efficiency of a 50kW charging stack at 25 ° C is 93%, yet the billing effectiveness at -25 ° C is as reduced as 39%. This is mainly because the BMS will restrict the ranked temperature at reduced temperatures power.

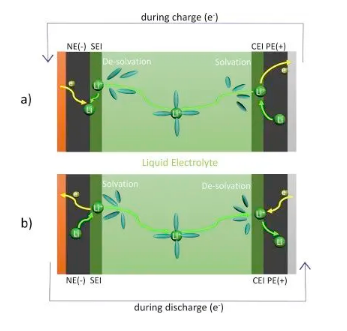

Common lithium-ion batteries mainly comprise graphite adverse electrodes, lithium steel oxide positive electrode, electrolytes, present collectors, and porous separator. As received Number 2, Li+ is sent from the favorable electrode to the adverse electrode through the electrolyte during charging. The major transmission paths are:

1) Via solid electrode;

2) Via the electrode/electrolyte user interface of the favorable and adverse electrodes;

3) After electrolyte, including solvation and desolvation of Li+.

Nevertheless, inappropriate use conditions of batteries typically cause a collection of adverse effects that affect efficiency and life. Furthermore, the cost and discharge rate, battery inner resistance and battery polarization will certainly influence the thermal qualities of the battery, such as enhancing heat production, minimizing charging effectiveness and safety, etc.

Figure2: Lithium ion transport diagram, a) charging, b) discharging

Many researches have shown that the depletion of the favorable electrode and the growth of the favorable CEI film have no effect on the rapid charging speed of conventional lithium-ion systems, so the negative electrode has become the main problem during the charging procedure. Under specific scenarios, lithium steel may continue precipitating right into lithium dendrites, pierce the separator, and trigger an interior short circuit. Elements influencing lithium deposition and deposition structure consist of the diffusion price of lithium ions in the unfavorable electrode, the electrolyte concentration gradient at the negative electrode user interface, metal salt deposition at the present enthusiast, and side reactions at the electrode/electrolyte user interface. The study reveals that the performance of the negative electrode throughout lithium deposition can be attributed to the influence of the present at the beginning of lithium deposition on the surface thickness and inner resistance of the unfavorable electrode. Lowering the inner resistance of the unfavorable electrode via battery design is very essential to boost the battery's rapid charging ability.

On top of that, the impact of temperature level is also extremely crucial. Too reduced or too high temperature level will certainly be thought about damage to the battery. However, a greater battery temperature level throughout quick billing will be beneficial to its very own balance, particularly for great details energy batteries. The influence of electrode density on billing efficiency also needs to be noticed. Thin electrodes are commonly thought about to offer suitable lithium ion transport. When the electrodes become thicker, it becomes essential to ensure adequate lithium ion concentration at the electrode/electrolyte interface to preserve overpotential stability and decrease the possibility of lithium advancement. During the quick billing procedure of thick electrode batteries, lithium salts may be deposited at the current collector, resulting in an imbalance in electrode utilization and an increase in the current thickness of the separator negative electrode.

High quality lithium-ion batteries supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for Lithium battery anode material,click on the needed products and send us an inquiry:sales@graphite-corp.com