What is the application of graphene oxide?

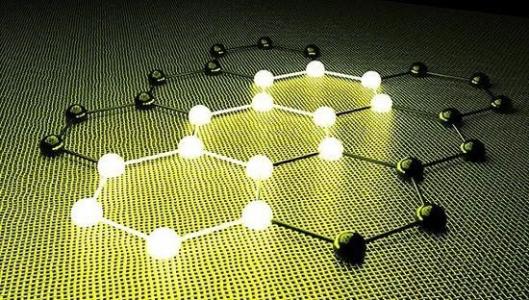

As an important derivative of graphene-based materials, although the highly conjugated structure of graphene is destroyed by the oxidation process, it still maintains special surface properties and layered structure. The introduction of oxygen-containing groups not only makes graphene oxide chemically stable, but also provides surface modification active sites and larger specific surface area for the synthesis of graphene-based/graphene-oxide-based materials. Graphene oxide, as the precursor and support carrier for the synthesis of graphene-based composites, is easy to functionalize and has high controllability. In the process of compounding with metals, metal oxides, polymers and other materials, it can provide a large specific surface area to effectively disperse the attached materials and prevent agglomeration.

Graphene oxide also shows its own excellent physical, chemical, optical, and electrical properties, and because of the coexistence of various oxygen-containing functional groups on the basal plane and edge of the graphene sheet skeleton, graphene oxide can be controlled by regulating the content of The type and number of oxygen-containing functional groups can be used to modulate its conductivity and band gap. The material has a wide range of applications. Graphene oxide is a new type of carbon material with excellent properties, with high specific surface area and abundant functional groups on the surface. Graphene oxide composite materials, including polymer composite materials and inorganic composite materials, have a wide range of applications, so the surface modification of graphene oxide has become another research focus.

1 Optoelectronics field

In 2016, Karteri et al. studied organic thin film transistors with SiO2/GO double insulating layers and their photoresponse devices. The addition of GO not only increased the types and thickness of insulating layers, but also enhanced the characteristics of transistors.

![]()

2 solar cells

Using GO instead of PEDOT:PSS as the hole transport layer of the polymer solar cell, a similar photoelectric conversion efficiency (PCE) was obtained. The influence of different GO layer thicknesses on the PCE of the polymer solar cell was studied, and it was found that when the thickness of the GO film layer was 2 nm , the device has the highest photoelectric conversion efficiency.

3 Flexible sensors

Because GO contains many hydrophilic functional groups, it is easy to be modified. In addition, it has a large specific surface area, good dispersibility, and good moisture-sensing properties, making it an ideal sensor material, especially in the field of flexible sensors.

3 biological aspects

The unique mechanical, electronic, and optical properties of GO make it play a huge role in biotechnology, biomedical engineering, nanomedicine, tumor therapy, tissue engineering, drug release, bioimaging, and biomolecular sensing. Compared with other spherical or planar nanomaterials, GO has a large specific surface area, high strength, easy modification, and good biocompatibility. Parameters such as size, surface charge, number of layers, lateral size, and surface chemistry of GO and its alkene derivatives will have corresponding effects on biological systems. Therefore, the biosafety of GO has limited its clinical application, including: Their cytotoxicity, in vivo toxicity, genotoxicity, and bioaccumulation in certain organs (eg, lung and liver) require further study. With the development of materials science, we will use materials with low toxicity and better biocompatibility to modify GO, so as to prepare GO with stable properties, clear structure, safety and non-toxicity, and make it as a safe and effective medical material. in wider clinical research.

High quality graphene oxide supplier

Luoyang Moon & Star New Energy Technology Co., LTD, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for Lithium battery anode material,click on the needed products and send us an inquiry:sales@graphite-corp.com