What factors affect graphite as a negative electrode for high quality lithium ion batteries?

What factors affect graphite as a negative electrode for high quality lithium ion batteries?

Graphite anode material is the main raw material of lithium ion battery anode sheet. Due to its rough processing technology, late start and industry specificity, the crystal structure, density and particle size and its distribution of graphite have effects on the performance of its battery. In addition, the product is prone to quality problems such as fiber foreign matter and fine powder.

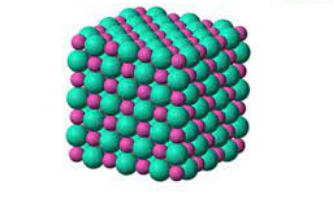

Crystal structure

The crystal structure of graphite has an important impact on its electrochemical performance. The more orderly the crystal structure of graphite is, the higher the degree of graphitization, the fewer corresponding lattice defects, the smaller the migration resistance of electrons, and the dynamic performance of the battery will be improved.

Particle size and particle size distribution

The particle size of the graphite anode material affects its electrochemical performance. The bit dimension of the anode product will directly influence the tap thickness of the material and the details surface of the product. Appropriate material particle size distribution can maximize the performance of the material.

Density

The density of graphite also affects its electrochemical performance. Tap density is the mass every unit volume measured when the powder is packed tightly by vibration. Appropriate material particle size distribution can maximize the performance of the material. The compacted density mainly refers to the density of the pole piece, which refers to the density after rolling after the negative active material and binder are made into the pole piece.

Fine powder

The proportion of fine powder of graphite anode seriously affects the processing technology of the battery factory. When the fine powder in the graphite negative electrode is higher than a certain ratio, the appearance of the produced negative electrode sheet may also have many small particles and scratches, resulting in the scrapping of the negative electrode sheet. The fine powder level of the graphite negative electrode is closely related to the process before graphitization and graphitization, and the fine powder that has been produced can be screened by a jet pulverization grading system. After the graphitization, the powder collides in the airflow device, and the collided powder becomes smaller. Under a certain airflow, the fine powder is blown out of the device and enters the fine powder collecting device, and the airflow through the adjusting device can be different. The graphite negative electrode of the particle size is sorted out, and the powder in the fine powder collecting device is removed, thereby obtaining a graphite negative electrode product whose fine powder level satisfies the customer's demand.

Fiber foreign matter

The metal foreign matter in the graphite anode powder and other visible foreign objects have been widely concerned. The anode manufacturing industry also controls the foreign matter in different stages of the manufacturing process according to the characteristics of foreign materials.

However, fiber foreign matter is a foreign object that everyone easily overlooks, and its influence on battery safety performance is increasing. When the amount of fibrous foreign matter reaches a certain level or accumulates in the powder, the appearance of the negative electrode sheet after coating is uneven, and electron beam and elemental analysis are performed on the uneven spots, and it is confirmed that the composition of the uneven spots is fiber.

The concave and convex points were observed under a microscope. It was found that the fibrous foreign matter occupied the position of the negative electrode powder. The amount of the negative electrode coating in this portion was reduced, thereby causing a lithium-inducing problem in the charging and discharging process of the battery, causing the explosion of the lithium ion battery.

Therefore, the quality control of fiber foreign matter is imperative. By testing the powders in each process, it was found that the negative electrode powder packaging bags used in each process were the main source of fibrous foreign materials.

Since the temperature of graphitization is high, the fiber can be carbonized. The carbonized fiber can be turned into fine slag through the vibrating screen and is present in the powder in the form of powder, which does not cause appearance quality problems on the pole piece, so The control of the fibrous material mainly manages the process after the graphitization.

After the graphitization process, a ton bag of fiber material is used in the turnover of the graphite negative electrode, which will rub with the equipment during transportation and feeding, thereby causing the fiber to fall off, and after the fiber is detached, it is easy to and the graphite negative electrode powder. The flow is transferred to the sieving process, and the fibers are sprinkled into the powder through the mesh of the screen after the powder is shaken for several hours on the screen of the vibrating screen.

To control the amount of fiber, firstly, protect the foreign material of the ton bag of fiber material, add a layer of plastic bag protection in the ton bag, or replace the ton bag with a plastic bucket. At the feeding port, a large-diameter screen is added to intercept the large bundle of fiber ropes, and the inlet of the feeding equipment is cuffed to prevent the equipment from scratching the bag and causing fiber problems.

Supplier

Graphite-crop corporate HQ is a high tech enterprise committed to the research and development, production, processing, sales and technical services of Silicon materials, we are high quality silicon supplier. Our Company has a diversified product structure with silicon carbon materials, and other negative materials (graphite materials, etc.). Please feel free to contact us. Or click on the needed products and send us an inquiry: sales@graphite-corp.com