The application of graphite powder for li-ion battery anode

Lithium battery is the third generation of small storage battery after nickel-tin battery and nickel-hydrogen battery. As a new type of chemical power source, it has the advantages of high operating voltage, large specific energy, flat and stable discharge potential curve, small self-discharge, long cycle life, good low temperature, no memory, no pollution, etc. The lithium battery can meet people's dual requirements of small and lightweight portable electric battery, it is very beneficial to environmental protection and widely used in mobile communication, notebook computer, camera and other small electronic devices, and it is also the ideal power source for future electric ac tools.

In lithium ion battery materials, the cathode material is the key to determine the battery energy. Graphite is a good cathode material for lithium ion cell due to its low embedding potential, excellent embedding ability and flat voltage platform.

Natural graphite whose source is rich with low price has been widely used in commercial lithium ion battery cathode materials, after the modification of the use has excellent quality and strong market competition. As a kind of graphite material with high crystallinity, the particle size of natural graphite directly affects the proportion of electrode specific surface area and edge carbon, which has a great influence on the irreversible specific capacity of the first charge. However, the influence of the initial physical parameters on the material properties of the negative electrode is rarely reported.

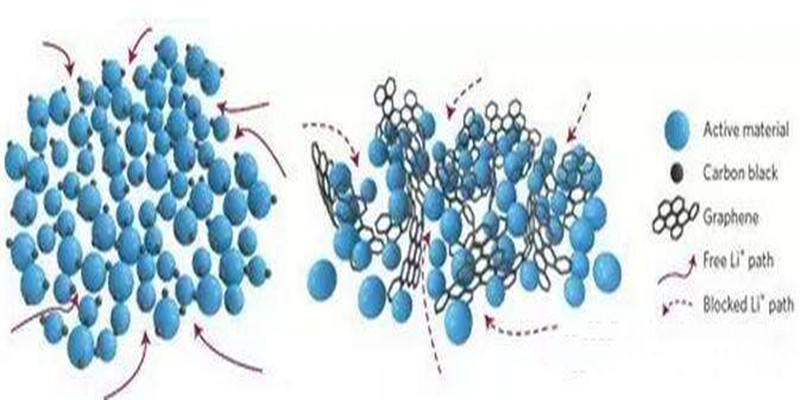

The increase of the particle size of graphite is beneficial to reduce the irreversible capacity loss of the first charge discharge.However, due to the longer diffusion path of lithium ion in the large particle size of graphite, the dynamic resistance of diffusion is larger and the anode polarization is increased.

The contact surface between the powder particles is less, the electron conduction ability is reduced. These factors affect the circulatory energy with the increase of the circulatory times.As the number of cycles increases, the tolerance is increased, and the circulatory energy becomes bad.

Considering the above reasons, the use of medium size stone ink material is beneficial to obtain a better synthesis of electrochemical properties. Taking S G 18 as an example, its particle size distribution has a slightly wider range, so that there is a certain amount of smaller powder filling between larger stone and ink particles.It is beneficial to improve the comprehensive performance of the negative electrode by increasing the contact surface product between particles, reducing the internal resistance and increasing the electronic conduction ability.

The particle size and distribution of natural graphite have a greater effect on the initial charge and discharge capacity of lithium ion battery, but a smaller effect on its first efficiency. The natural graphite powder with smaller particle size has larger capacity of first charge, but its irreversibility is also larger. The natural graphite with medium size has a higher initial efficiency. With the increase of the granule size, the first charge and discharge capacity decreases.The irreversible capacity of the graphite powder with smaller particle size increases. When the cell size was 16 ~ 18 Ds and the particle size distribution is concentrate, the battery had better initial discharge capacity and first efficiency.

High quality graphite manufacturer

If you need graphite powder, please feel free to contact: sales@graphite-corp.com