Super quick billing method for lithium-ion power batteries

Although numerous services to a material degree have good outcomes, their commercialization is still hard to attain in the near future. Researchers have scooted billing remedies to the battery and Load levels to be used in the short term. The design of the charging method is essential to solving this problem.

Kinds of billing techniques

Standard charging

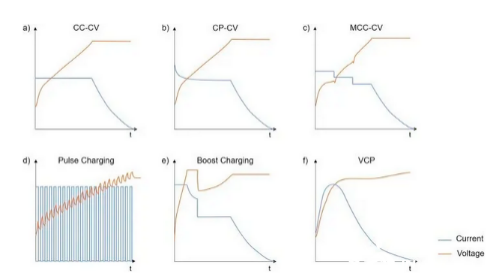

CV is currently one of the most common billing procedures: an initial charge with the constant present to the cut-off voltage (CC phase) and, after that, a charge with consistent voltage to a tiny current close to 0 (CV phase). The constant voltage procedure can make the ion concentration circulation in the electrode product a lot more uniform, which is essential for the product to exert a high details capability; however, the current at continuous voltage gradually lowers, making the billing time of curriculum vitae significantly longer than that of CC. The straightforward operability of the CC-CV charging mode makes it one of the most widely used conventional charging protocols. Yet numerous other vital strategies can reduce billing time, boost billing efficiency, and enhance capacity/power retention. Number 1 reveals several usual rapid billing strategy contours.

Figure 1: Common fast charging strategy curves a) constant current-constant voltage (CC-CV); b) constant power-constant voltage (CP-CV); c) multi-stage constant current-constant voltage (MCC-CV); d ) Pulse charging; e) CC-CV-CC-CV mode continuous charging (Boostcharging); f) Variable current charging (VCP)

Figure 1 Common quick charging strategy curves a) consistent current-constant voltage (CC-CV); b) continuous power-constant voltage (CP-CV); c) multi-stage continuous current-constant voltage (MCC-CV); d) Pulse billing; e) CC-CV-CC-CV setting continual charging (Boostcharging); f) Variable current charging (VCP).

Multi-stage constant existing charging

Several researchers have proposed that changing the existing charging procedure can slow down the battery's aging and lower the billing time. The objectives of these studies are typically to minimize warm production, prevent lithium deposition, or lower mechanical stress and anxiety. MCC is just one of the earliest strategies for fast charging. It includes two or even more actions of the constant current phase, followed by a consistent voltage phase. Considering that the capacity of the adverse electrode at the start of billing can not easily go down to the lithium advancement potential, the present in the early CC phase is bigger. Nonetheless, some researchers embrace the contrary billing method; that is, the CC section present progressively rises because the inner resistance of the battery will slowly lower.

Pulse charging

Throughout the pulse billing procedure, the current modifications regularly to lower focus polarization, prevent local potential from becoming unfavorable or minimize the rise in mechanical stress and anxiety brought on by regional lithium ion deintercalation.

Enhance billing

A bigger typical current is utilized in the first charging stage, and the present is reduced for CC-CV charging. The initial charging stage can be a CC phase (the whole charging strategy amounts to MCC-CV), a curriculum vitae stage after the battery voltage gets to the set maximum voltage (CV-CC-CV), or a total CC-CV stage (CC-CV -CC-CV). This strategy sets higher present and voltage than CC-CV to reduce the total billing time. Nevertheless, under the same charging time, the capability of improved billing degenerations is faster than that of CC-CV, while pulse charging has no evident distinction from CC-CV. Some scientists have revealed that CC-CV is appropriate for rapidly charging high-power batteries, and MCC is typically utilized in accountable situations prone to lithium precipitation.

Variable existing charging

In order to achieve fast charging, some researchers have proposed a series of more complex variables that present billing contours, consisting of VCD, UVP, and so on. As the battery ages, the present contour requires to be changed based on modifications in interior resistance at the same voltage. In addition to aging aspects, the present is always low in the first charging stage and then rises rapidly. This is because the inner resistance of the battery at 0% SOC is the largest and then decreases swiftly. The optimum existing usually shows up in the lower SOC area. Then, the existing gradually lowers due to the boost in the amount of lithium installed in the particles and the constraint of Li transmission. Additionally, the temperature level circulation inside the battery and Pack during charging is crucial. Yet, billing control approaches frequently only take into consideration surface temperature level as the major factor in depletion.

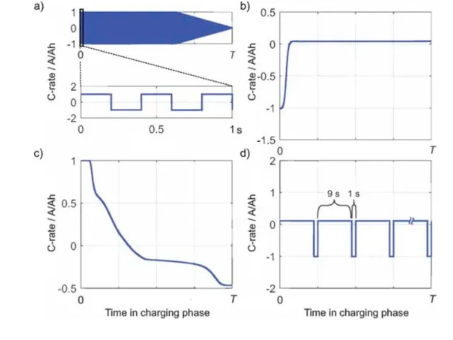

Schindler incorporated various billing strategies in Number 2 to conduct cycle experiments on the battery and contrasted it with CC-CV to examine the ability of the battery to fade under various cycles. The outcomes show that by incorporating all charging techniques for cycle experiments, the battery preserves 80% capacity after 800 cycles, the best performance among all cycles; the battery with only CC-CV cycle rots to the very same capacity just 400 times; while CC -Under the combined cycle of curriculum vitae and chilly derating, the battery only cycled 330 times, revealing the worst efficiency.

Figure 2: Current curve

Many fast-charging strategies operate at typical temperatures and specific battery setups. Because large currents will cause better mechanical tension inside the electrode particles, accompanied by significant irregular current and temperature circulation, treatment needs to be taken when quick charging is utilized for various sorts of batteries. The universality of several current billing strategies still lacks additional speculative confirmation. With the promo of electric automobiles in low-temperature locations, more research on quick billing methods at reduced temperature levels is needed. On top of that, it is the battery's temperature instead of the ambient temperature that identifies the performance of the battery. Changes in battery temperature during the charging procedure also require to be considered. Lastly, the influence of different charging methods at the load level must still be examined urgently.

High quality lithium-ion batteries supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for Lithium battery anode material,click on the needed products and send us an inquiry:sales@graphite-corp.com