Natural flake graphite: "taking the lead" in the field of graphite

Introduction to natural flake graphite

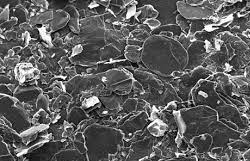

Natural flake graphite is a very important natural mineral. It is composed of carbon elements and has a layered structure and crystal structure. Its appearance is black, its surface has a metallic luster, its texture is soft, and it has specific conductive properties.

Flake graphite is formed by high-pressure transformation. It is generally blue-gray, and the weathered layer is brown or gray-white. It is mostly produced in gneiss, schist, crystal basalt and skarn. The interdependent minerals are complex and the main component is block. Crystalline carbon is accompanied by residual minerals such as marble, quartzite, biotite, hematite, pyrrhotite, and rutile. High-purity graphite in iron ore is crystalline porphyry or leaf-like, black or steel gray. It is mainly stored in marble, quartz or diopside, and diopside particles, with obvious ordering. , consistent with the layer orientation. Most of the flake graphite is pure natural crystalline high-purity graphite with a lamellar structure. It is nearly scaly in shape and belongs to the hexagonal crystal system. The crystal state is good, the particle size distribution diameter is 0.05 to 1.5 μm, and the flake thickness is 0. 02~0.05mm, the larger scales can reach 4~5mm, and the high purity graphite carbon content is generally around 2%~5% or 10%~25%.

Flake graphite is mainly distributed in Australia, Brazil, Canada, China and Madagascar. In China, flake graphite is concentrated primarily on Heilongjiang, Shandong and Inner Mongolia. The Luobei area of Heilongjiang has the largest reserves of flake graphite mineralization in my country, with reserves of 13.48 million tons. Flake graphite can be produced into three grades of products. Grade 1 high-purity graphite flakes have larger diameters, grade 2 high-purity graphite flakes have medium size, and grade 3 is fine flake graphite. After sorting and aggregation, the carbon content of flake graphite is generally 80 %~99.5%.

Mining and processing of natural flake graphite

Natural flake graphite's mining and processing methods are relatively simple, generally using mechanical stripping methods and chemical etching methods. The mechanical stripping method strips the natural flake graphite from the ore and then cleans and dries it. The chemical corrosion rule is to put natural flake graphite into an acid solution and separate the natural flake graphite from the ore through the corrosion effect of the acid solution.

Application of natural flake graphite

Natural flake graphite has a wide range of uses, the most important of which is in the fields of metallurgy and machinery manufacturing.

In the field of metallurgy, natural flake graphite can be used as a lining material for crucibles and smelting furnaces. It can withstand high temperatures and high-intensity smelting processes and improve the quality and output of metallurgical products.

In the field of machinery manufacturing, natural flake graphite can be used to manufacture various mechanical parts and molds. It has high strength, high wear and corrosion resistance characteristics, and can improve the performance and service life of mechanical equipment.

In addition, natural flake graphite can also be used in the electronics and chemical industries. In the field of electronics, natural flake graphite can be used to manufacture electronic devices such as batteries and capacitors. It has high conductivity and stability characteristics and can improve the performance and reliability of electronic devices.

In the chemical industry, natural flake graphite can be used to manufacture various chemical products, such as graphite emulsion, graphite coatings, etc. It has high corrosion resistance and stability characteristics and can improve the quality and performance of chemical products.

Uses of flake graphite

1) Refractory materials

Flake graphite is broadly used in the metallurgical industry's advanced refractory materials and coatings. Such as magnesia carbon bricks, crucibles, etc. Stabilizer for pyrotechnic materials in the military industry, desulfurization accelerator in the smelting industry, pencil lead in the light industry, carbon brushes in the electrical industry, batteries in the fertilizer industry, etc.

After in-depth flake graphite processing, graphite emulsion can be produced and used for lubricants, release agents, drawing agents, conductive coatings, etc. Expanded graphite can also be generated and used as basic material for adaptable graphite products, such as graphite seals and composite products.

2) Coating

As a functional filler in coatings, flake graphite is mainly used in anti-corrosion, fire retardant, and conductive coatings.

As an anti-corrosion product, it and anti-rust primers made from carbon black, baby powder and oil have excellent resistance to chemicals and solvents. If chemical pigments such as zinc yellow are contributed to the formula, the anti-rust impact will be much better.

Expandable graphite is used as a fire-retardant coating. It is a graphite interlayer compound obtained by chemical or electrochemical treatment using natural graphite flakes as raw materials. Expandable graphite rapidly expands in volume (up to 300 times) when heated, suffocating the flame and generating expansion materials to isolate the flame and delay or disrupt the spread of the flame. It is non-flammable and has good softness and high surface energy. , the carbonized layer has good strength. However, the volume and dosage of the expansion body must be selected appropriately. Tests have shown that 150um particles, an expansion factor of 30%, and a dosage of 5% are most suitable.

Flake graphite can be directly used as carbon conductive filler or made into composite conductive filler for conductive coatings. However, due to the large addition of graphite flakes, the performance of the coating will become brittle and its application will be subject to certain limitations. As a result, procedures are required to enhance graphite's conductivity and efficiently decrease the quantity of graphite flakes added. The residential Tianhua Chemical Equipment Research Study Institute created a product that makes use of high-temperature corrosion-resistant resin as the primary material and large, strong graphite flakes with solid electrostatic conductivity as the main accumulation. It has high body strength and good wear resistance.

3) Expanded graphite

As a new kind of functional carbon material, expanded graphite (EG) is a loose and porous worm-like substance obtained by intercalating, washing, drying and high-temperature expansion of natural graphite flakes. Large flake graphite and fine-grained graphite must be used for production. Levels cannot be used or are difficult to use.

4) Graphite negative battery material

Graphite has excellent electrical conductivity, 100 times higher than that of ordinary non-metallic minerals. It is currently the most widely used negative electrode material for lithium-ion batteries. Both flake and artificial graphite can be used as battery anode materials, and each has its advantages. However, earthy graphite cannot be used as a graphite anode battery material because its capacitance is too low.

Is flake graphite natural graphite?

Flake graphite is natural graphite. Graphite is divided into artificial graphite and natural graphite. Flake graphite is a natural crystalline graphite which is extracted directly from flake graphite ore. The graphite raw material mined from the flake graphite ore is processed through raw ore crushing, wet rough grinding, rough selection, coarse concentrate regrinding and selection, selection, dehydration and drying, and graded packaging to obtain the finished flake graphite.

What are the specifications of flake graphite?

Flake graphite comes in various specifications, usually in powder form. Depending on the size of the flakes, flake graphite can be divided into large flake graphite and fine flake graphite. Large flake graphite refers to +50 mesh, +80 mesh, +100 mesh flakes. Graphite and flake graphite below these mesh numbers is called fine flake graphite.

Supplier

Graphite-crop corporate HQ is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of Silicon materials, we are high quality silicon supplier. Our Company has a diversified product structure with silicon carbon materials, and other negative materials (graphite materials, etc.). Please feel free to contact us. Or click on the needed products and send us an inquiry: sales@graphite-corp.com.