Innovative flake graphite technology to promote progress in materials science

Graphite is a carbonaceous non-metallic mineral and a high-performance crystalline carbon material. It has extraodinary thermal conductivity, electrical conductivity, high and low temperature resistance, radiation resistance, corrosion resistance, self-lubrication and other properties. It is widely used in metallurgy, machinery, automobiles, and atomic energy. , medicine, military industry, batteries, aerospace and other fields, it has actually become one of the crucial raw materials for materials in high, brand-new and advanced scientific and technological fields in the 21st century. In recent years, many developed countries have listed graphite as a strategic mineral for protection. In order to improve resource supply capabilities and development and utilization levels.

Category of graphite

The process characteristics of graphite mainly depend on its crystal form. According to the different crystal forms, natural graphite can be industrially divided into three categories: dense crystalline graphite (lumpy graphite), cryptocrystalline graphite (earth graphite) and flake graphite. .

Flake graphite is relatively rare in nature and is the most valuable graphite ore. It has the best crystallization state, with a particle diameter greater than 0.1mm. The crystals are visible to the naked eye. The specific surface area ranges from 0.1 to 1m2/g, and it has a dense block structure. The fixed carbon content is 60% to 65%, sometimes as high as 80% to 90%, but its plasticity and smoothness are not as good as flake graphite.

Earthy graphite has the worst crystallization state, with a crystal diameter less than 1 μm and a specific surface area mainly distributed between 1 and 5 m2/g. It is an aggregate of microcrystalline graphite. The complete crystal form can only be seen under an electron microscope. The surface is earthy. Shape, lack of luster and lubricity, poor floatability, but higher grade, fixed carbon content is generally 60% to 80%, and a few can reach more than 90%.

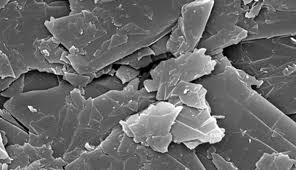

Flake graphite is one of the most floatable ores in nature. After multiple grinding and multiple separations, high-grade graphite concentrate can be obtained. The floatability, lubricity, and plasticity of this type of ore are superior to Other types of graphite, so its industrial application value is greatest.

Overview of flake graphite

Flake graphite is formed by high-pressure metamorphism. It is generally blue-gray in color and becomes yellow-brown or off-white when weathered. It is mostly found in gneiss, schist, crystalline limestone and skarn. The symbiotic minerals are complex and the main component is flake crystalline carbon, accompanied by There are impurity minerals such as feldspar, quartz, biotite, pyrite, pyrrhotite, and rutile.

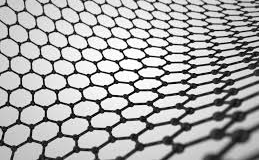

The graphite in the ore is in the form of crystalline scales or blades, black or steel gray, and is mainly found between feldspar, quartz or diopside and tremolite particles. It has an obvious directional arrangement and is consistent with the layer direction. Most of the flake graphite is natural crystalline graphite, which has a layered structure. It is shaped like fish scales, belongs to the hexagonal crystal system, and has a good crystallization state. The particle size diameter is 0.05~1.5μm, the flake thickness is 0.02~0.05mm, and the largest flake can reach 4 ~5mm, graphite carbon content is generally around 2% ~ 5% or 10% ~ 25%.

Classification and application of flake graphite

According to the total graphitic carbon content (Total Graphitic Carbon, TGC), flake graphite is divided into high purity graphite (TGC ≥ 99.9%), high carbon graphite (TGC 94.0% ~ 99.9%), medium carbon graphite (TGC 80.0% ~ 94.0% ) and low carbon graphite (TGC ≤ 50.0% ~ 80.0%) four categories. According to the size of the scales, flake graphite is divided into large flake graphite (>147m) and small flake graphite (<147m).

Flake graphite application areas

Flake graphite resource reserves and production

Natural flake graphite deposits are the main type of graphite deposits in the world. They are mainly found in China and Sri Lanka in Asia, Ukraine in Europe, Mozambique, Madagascar, Tanzania in Africa, and Brazil in South America. Mozambique, Tanzania, Madagascar and other countries are rich in them ( Super) large flake graphite has high industrial value.

The "MINERAL COMMODITY SUMMARIES 2021" released by the United States Geological Survey (USGS) shows that as of the end of 2020, the world's proven natural flake graphite reserves were 230 million tons, of which China, Brazil, Madagascar, and Mozambique accounted for more than 84% .

At present, the main producing countries of natural flake graphite are China, Brazil and India. From 2011 to 2016, the global production of natural flake graphite remained stable at 1.1 to 1.2 million t/a. Affected by a series of factors, it plummeted to 897,000 tons in 2017; slowly rose to 930,000 tons in 2018; and recovered to 1.1 million tons in 2019 due to the increase in the supply of natural flake graphite in Mozambique. In 2020, China's flake graphite output was 650,000 tons, accounting for approximately 59% of the world's total output, making it the world's largest producer; Mozambique's flake graphite output was 120,000 tons, accounting for 11% of the world's total output, making it the second largest producer. Producing countries.

Ore dressing and purification of flake graphite

The purity of graphite determines its use. As the application scope of graphite continues to expand, the requirements for its purity are becoming higher and higher. Experimental research and industrial practice show that different purification methods have different advantages and markets

Flotation method: Flake graphite has good natural floatability. After flotation, enrichment and purification, a concentrate product with a fixed carbon content of more than 90% can be obtained. The flotation process is unique. It must not only increase the fixed carbon content of the concentrate, but also increase the yield of large scales. However, the fixed carbon content of the raw ore is generally not high, about 3% to 10%. The process mineral processing ratio is large and rich. The degree of concentration is high and multi-stage grinding is required to achieve gradual dissociation from gangue minerals. Usually, the stage grinding stage flotation process is adopted. Exploring how to protect large flakes in flake graphite flotation, rationally optimizing the grinding process and flotation process, and improving large flake yield and concentrate quality are the mainstream development trends of flake graphite beneficiation.

Alkaline-acid method: It is a purification method for flake graphite that is currently widely used and has relatively ideal purification effects. However, this process has high energy consumption, complex processes, and large water consumption.

Hydrofluoric acid method: The effect of purifying graphite is remarkable, but hydrofluoric acid is highly toxic and seriously pollutes the environment, so its use is restricted.

Chlorination roasting method: The effect of purifying graphite is limited, and chlorine gas is toxic and harmful to health and environmental protection, and requires high equipment.

High-temperature method: It is an effective means to achieve ultra-pure graphite production, but this method has extremely high requirements for raw materials and equipment.

Global flake graphite trade pattern

At present, China, Brazil, Mozambique, Madagascar and other countries are the main exporters of natural flake graphite in the world, and China, the United States, India, Japan, Germany, Canada and other countries are the main importers. China is both a major exporter and a major importer of natural flake graphite. It is one of the world's largest producers and consumers of graphite and plays an important role in the global graphite trade market.

China mainly exports rough-processed, low-value-added graphite products such as raw flake graphite ore and low-grade flake graphite, while developed countries such as the United States, Japan, and Germany mainly export deep-processed, high-value-added graphite such as fluorinated graphite, expanded graphite, and high-purity graphite. graphite products.

Supplier

Graphite-crop corporate HQ is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of Silicon materials, we are high quality silicon supplier. Our Company has a diversified product structure with silicon carbon materials, and other negative materials (graphite materials, etc.). Please feel free to contact us. Or click on the needed products and send us an inquiry: sales@graphite-corp.com