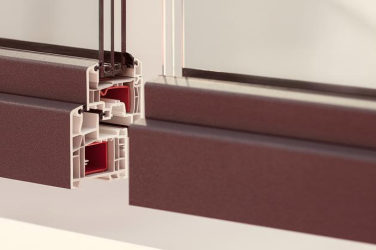

Expandable graphite can be used as a flame retardant and fireproof material - used for sealing strips of fire doors and fireproof glass windows

Application of expanded graphite in fireproof sealing materials

Due to the expandability and high temperature resistance of expanded graphite, expanded graphite has become an excellent sealing material and is widely used in fireproof sealing strips. There are two main forms: the first is to mix and vulcanize expanded graphite materials with rubber materials, inorganic flame retardants, accelerators, vulcanizing agents, reinforcing agents, fillers, etc., to make expanded sealing strips of various specifications. In fire doors, fire-resistant glass windows, and other occasions, this kind of inflatable sealing strip can block the flow of smoke from beginning to end at normal temperatures and in fires. The other is to use glass fiber tape as a carrier, and the expanded graphite is bonded to the carrier with a certain adhesive. The shear resistance provided by the carbide formed by this adhesive at high temperatures can effectively prevent graphite from Being damaged. It is mainly used for fire doors but cannot effectively block the flow of cold smoke at normal or low temperatures, so it must be used in conjunction with normal-temperature sealant.

Protect life and protect safety - the importance of fire door seals

As people's awareness of safety continues to increase, fire doors and important passageway devices in buildings are widely used in public places, residences, shopping malls, and industrial areas. As a key component of fire doors, the fire door sealing strip cannot be ignored.

A fire door sealing strip is a sealing material made of rubber or silicone installed on the fire door. It is used to fill the gap between the door frame and the door frame to achieve a complete seal between the door frame and the door. Its main function is to prevent smoke, flames, heat, and harmful gases from entering other areas through door gaps, thereby slowing the spread of fire and protecting people's lives and property.

First of all, fire door seals can effectively isolate smoke. In a fire, smoke is one of the most deadly threats. By installing the sealing strip correctly, you can seal the door gaps and prevent the penetration of smoke. According to statistics, most fire casualties are caused by inhalation of toxic smoke. Therefore, the role of fire door sealing strips at fire scenes must be addressed. It can buy people valuable escape time.

Secondly, fire door seals can effectively isolate flames and heat. Door gaps often accelerate the rapid spread of flames in a fire. Applying sealing strips can effectively inhibit the spread of flames and reduce fire spread to other areas. In addition, the sealing strip can also play the role of heat insulation, prevent the fire from radiating heat to the surrounding environment, and provide more time for firefighters to carry out fire extinguishing and rescue work.

Finally, fire door seals can also isolate harmful gases and provide people with a safer escape environment. During a fire, the harmful gases produced are often one of the main causes of casualties. Sealing strips can effectively reduce the spread of harmful gases and give people more opportunities to escape from a fire.

Remember, fire door seals are not excessive; they are a protective barrier in our buildings to withstand the threat that fire poses to us. Its importance cannot be ignored because it is directly related to our safety and life.

However, more than having a fire door seal alone is required to ensure safety. Correct use and routine maintenance are equally important. First, we should follow the correct installation requirements to ensure that the sealing strip is correctly installed in the gap between the door frame and the door. The sealing strip should fit tightly without any gaps. Secondly, we should regularly check the condition of the sealing strips. If there is any aging, damage, or looseness, replace it and repair it in time. Unqualified sealing strips cannot function properly and may even cause safety hazards.

Supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for graphite powder for battery li-ion anode, click on the needed products and send us an inquiry: sales@graphite-corp.com