Essential information for lithium batteries: polarization and differential curve analysis

Polarization analysis

During lithium batteries' billing and discharging process, polarization is unpreventable, particularly throughout high-rate charging and discharging. It is essential to research the capacity adjustments caused by polarization and evaluate the polarization according to the cost and discharge contours. Compared with assessing the electrode procedure kinetics through GITT, continuous voltage periodic titration (PITT) or electrochemical impedance spectroscopy (EIS) is required to analyze the polarization via cost and discharge. The kinetic details gotten from the curve are a lot more user-friendly. The capacity measured at reduced cost and discharge rates (such as 0.05 C, 0.02 C, 0.01 C or reduced prices, relying on the material) can essentially disregard the capacity change brought on by polarization. The difference between the ability value tested at a particular rate and the ability value examined at that reduced price can be considered a change in ability triggered by polarization. In the constant current-constant voltage (CC-CV) charging continuous present discharge contour, the polarization situation can be characterized by the proportion of the continuous present billing capability and the continuous voltage charging capability in the billing contour to the complete ability. The reduced proportion of consistent present billing ability to total billing capability or the higher the proportion of continuous voltage charging capability to total billing capacity, the greater the polarization.

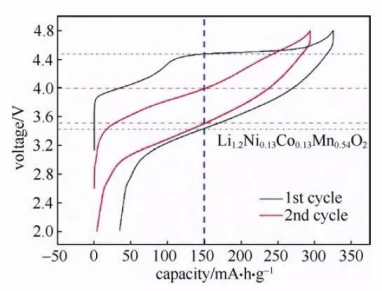

Figure 1: Charge and discharge curves of lithium-rich cathode material (Li1.2Ni0.13Co0.13Mn0.54O2)

Furthermore, the rise in the charge-discharge plateau voltage difference in the charge-discharge curve can likewise mirror the increase in electrode polarization. This difference is easier to review in the "cyclic" charge-discharge curve. An initial understanding can be made via the difference in the upright axis of the cost and discharge contour of this contour. In Number 4, the cost and discharge contour of the lithium-rich cathode material (Li1.2 Ni0.13 Co0.13 Mn0.54 O2) is compared to the contour of the very first cycle. The void in the vertical axis of the 2-cycle cycle contour is smaller sized, suggesting a decrease in polarization. On top of that, this value can also be characterized by the possible distinction between the lithium insertion and elimination optimal in the differential tolerance contour. As the potential distinction becomes larger, the polarization boosts.

Differential curve analysis

In evaluating the battery charge and discharge curve, the curve is differentiated, and the plateau location is exchanged for a peak curve to facilitate the research study of the cost and discharge curve. The frequently made use of techniques is the differential capacity curve (step-by-step capability, dQ/dV vs. V) and various voltage curve (differential voltage, dV/dQ vs. Q) to measure the charge and discharge curves.

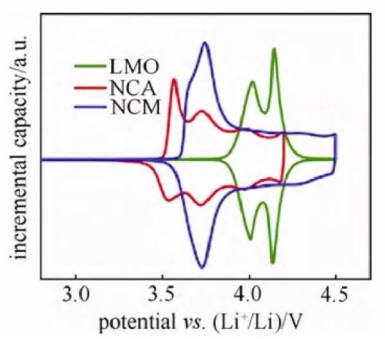

figure 2: Differential tolerance curves of half cells with several cathode materials

Among them, the differential resistance curve, described as the IC contour (Number 5), is extensively used. Nevertheless, as a result of the existence of a voltage platform (i.e., dV=0), information processing needs to be cautious. The oxidation and decrease peaks in the contour correspond to the billing and discharge plateau in the charge-discharge curve and have an equivalent relationship with the oxidation peak and decrease top in the cyclic voltammetry contour. According to the peak setting in this curve, a referral can be made to validate and judge the redox reaction. The cost and discharge curves of the exact same cycle are differentially refined, and the peak placements are compared and presented. The intermediate value corresponding to the redox optimal capacity is the thermodynamic equilibrium capacity. In addition, the motion and depletion of the peak placement also have specific relative values. For example, the behavior of the peak position indicates that the charge and discharge plateau possibility near the potential has actually moved, which belongs to the problem of intercalation and extraction of lithium caused by the architectural changes of the material; the intensity change of a certain peak placement can represent the modification in the length of the fee and discharge plateau of that potential.

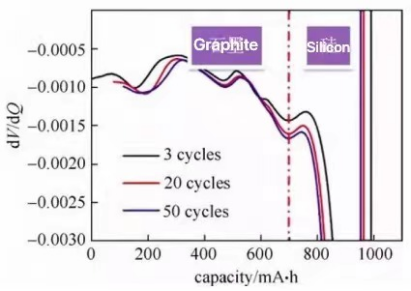

Figure 3: Differential voltage curve of silicon-carbon hybrid material/metal lithium sheet half-cell during discharge

Differential voltage contour, referred to as dV contour, can be based upon literature or speculative comparison curve optimal placement acknowledgment, and based on the abscissa of the peak placement, the capability performance of various products or systems can be preliminarily evaluated. The information processing of this contour is more convenient and is primarily used for mixing In the analysis of material pole items. Figure 3 reveals the dV curve of the silicon-carbon hybrid material/metal lithium sheet half-cell discharge process. Via relative evaluation, it can be wrapped up that in the 3rd cycle of discharge ability, the silicon material puts in a capability of 293 mA · h, and the graphite puts in a capacity of 293 mA · h. It is 697.6 mA · h, and the capacity of silicon and graphite both decreases with cycles. It needs to be kept in mind that whether the data of differential capacitance and differential voltage contours are smooth has an effect on the voltage dimension precision, current control accuracy of the cost and discharge instrument, the temperature level stability throughout testing, and the density of tasting points.

High quality lithium-ion batteries supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for Lithium battery anode material,click on the needed products and send us an inquiry:sales@graphite-corp.com