Essential information for lithium batteries: Voltage analysis and capacity analysis

Voltage analysis

The open circuit voltage of the constructed lithium-ion battery refers to the prospective distinction between the favorable and adverse electrodes when no present circulations through the external circuit. It can be straight measured by a multimeter (accuracy is not less than 0.1 mV; it is suggested to use a special voltmeter with high inner impedance to prevent self-discharge) or review the worth straight after linking to the battery test system. This worth is only the initial open circuit voltage after the battery is constructed. The open circuit voltage under full SOC requires to be determined by the galvanostatic recurring titration (GITT) approach, which will certainly be presented in a succeeding write-up. The working voltage refers to the immediate prospective difference between the favorable and adverse electrodes when current circulates with the external circuit, which can be shown straight in the battery examination system data. Working voltage U= E0 ± IRi, where E0 is the thermodynamic stability voltage, Ri is a particular resistance inside the button battery or in contact, such as the ohmic resistance, fee transfer resistance, diffusion resistance of a specific structural component, I for the test existing. The operating voltage is associated with the current dimension.

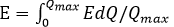

The average discharge voltage analysis calls for formula processing of the curve, that is,  important completely dry details for lithium batteries. Charge and discharge examination data evaluation. In the formula, Qmax is the discharge capacity in the contour, and E is the ordinate voltage of the discharge contour.

important completely dry details for lithium batteries. Charge and discharge examination data evaluation. In the formula, Qmax is the discharge capacity in the contour, and E is the ordinate voltage of the discharge contour.

Ability evaluation

Battery capacity is just one of the crucial performance indicators of lithium-ion battery performance. It shows the amount of power saved in a lithium-ion battery under particular problems, typically in systems of A · h (ampere-hour) or mA · h( milliamp-hour )( 1 A · h= 1000 mA · h), the major technique used to get the capability parameters of lithium-ion batteries is to incorporate the existing with time when the battery is released from 100% SOC to 0% SOC (within the examination voltage range), that is the lithium battery Crucial dry information. Charge and discharge examination information analysis, where Q is the battery capacity (A · h), I is the existing (A). T is the test time (h ). 1 milliamp amounts to 3.6 coulombs. In general, capability information can be checked out straight in the test system software.

the lithium battery Crucial dry information. Charge and discharge examination information analysis, where Q is the battery capacity (A · h), I is the existing (A). T is the test time (h ). 1 milliamp amounts to 3.6 coulombs. In general, capability information can be checked out straight in the test system software.

For the tested battery materials, capacity evaluation normally needs to figure out three pieces of information: very first cost capacity, very first discharge ability (positive electrode material) and reversible capacity.

a. The initial billing capability is the billing ability of the lithium-ion battery at the end of the initial fee;

b. The first discharge capability is the discharge capability of the lithium-ion battery at the end of the initial discharge;

c. The reversible capacity is the ability value after the battery cycle is secure (the examination worth at a typical temperature level is likewise called the rated ability). Usually, the discharge capacity in the 3rd to fifth weeks is chosen. Occasionally, it may be necessary to choose the discharge ability after 10 weeks.

In functional applications, the evaluation of the gram ability, surface capability and volume capacity of the test material or post piece has even more referral worth. For example, gram capability is the discharge capacity of each mass of active material, C= Q/m; surface capability is the discharge ability of each location of the test electrode piece, C= Q/S; quantity ability is the discharge capability per unit electrode item volume, C= Q/ V. In the formula, C is the discharge details capability mA h/g (milliamp hours per gram), mA h/cm2 (milliamp hours per square centimeter) or mA h/cm3 (milliamp hours per cubic centimeter), Q is discharge capacity mA · h( milliamp hours), m is the mass of the active product g (grams), S is the area of the examination electrode piece cm2 (square centimeters), and V is the quantity of the test electrode piece cm3 (cubic centimeters). The gram capacity criterion is extra user-friendly for contrasting the performance of the test material, while the surface capacity and volume capability are of even more recommendation value for the real application of the test material and when the favorable and negative electrode capacities are matched. It is suggested to supply three sorts of certain capacity details at the same time when releasing an article.

Switch battery data can additionally review the power density (W) of the favorable energetic product, which refers to the energy that can be kept and launched per unit mass of the positive energetic product. W= EQ/m is the item of the typical discharge voltage and gram ability. The commonly utilized unit is W · h/kg (often called particular power), which additionally includes the volumetric power density W · h/L. Generally, the mass proportion of favorable active material in the battery core is 30% to 50%. The details proportion depends upon the favorable electrode product's compressed density and genuine thickness. For that reason, based on the power density of the cathode active material, the matching complete battery's power density can also be estimated. This is of reference relevance for those who do not have problems establishing a full battery but want to assess the cathode product and anticipate the energy thickness of the cell advantages.

High quality lithium-ion batteries supplier

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for Lithium battery anode material,click on the needed products and send us an inquiry:sales@graphite-corp.com