Artificial graphite leads the new trend in the global new material field

Fabricated graphite, as the name recommends, is graphite made by artificial techniques. It is similar to polycrystals in crystallography. There are many sorts of synthetic graphite, and the manufacturing processes vary commonly. In a wide sense, all graphite products gotten by carbonization of organic matter and high-temperature treatment of graphitization can be jointly described as artificial graphite, such as carbon (graphite) fiber, pyrolytic carbon (graphite), foam graphite, and so on. In a slim feeling, artificial graphite generally describes carbonaceous raw materials with low impurity content (oil coke, pitch coke, and so on) as aggregate and coal pitch as binder, via batching, kneading, molding, and carbonization (sector labeled It is a block solid material produced by processes such as roasting) and graphitization, such as graphite electrodes, isostatic graphite, and so on.

There are numerous means to make synthetic graphite. The most common one is to utilize powdered top quality calcined oil coke as the major raw material, add asphalt as a binder, and add a small amount of other complementary materials. After the numerous mixes are completed, they are pushed and created and then treated in a non-oxidizing gas at 2500 to 3000 levels Celsius to graphitize them.

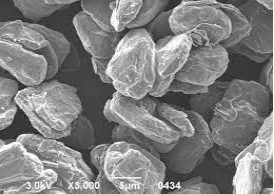

Synthetic graphite is available in many kinds, consisting of powder, fiber and block. Artificial graphite in the narrow feeling is usually in block kind and requires to be processed into a specific form when used. It can be regarded as a multi-phase product, consisting of the graphite stage changed by carbonaceous particles such as oil coke or pitch coke, the graphite phase changed by the coal pitch binder layer around the fragments, fragment buildup or coal pitch binder Pores formed after warmth treatment, etc. Typically talking, the higher the heat treatment temperature, the higher the level of graphitization. The level of graphitization of industrially produced synthetic graphite is typically less than 90%.

Compared to all-natural graphite, fabricated graphite has weak heat transfer performance, electric conductivity, lubricity and plasticity, but synthetic graphite likewise has the advantages of much better wear resistance, deterioration resistance and reduced leaks in the structure than natural graphite.

Currently, artificial graphite products are mostly used in complying with facets:

Graphite electrodes

It is mostly made from petroleum coke and needle coke as basic materials and coal pitch as binding agent. It is made by calcining, batching, working, pushing, roasting, graphitization and machining. It launches electrical energy in the form of arc in an electrical arc heater to bill the fee. Conductors that are heated up and thawed can be split into common power, high power and ultra-high power according to their top quality signs. Graphite electrodes consist of:

1) Normal power graphite electrode. It is enabled to make use of graphite electrodes with a current density lower than 17A/cm2, which are primarily used in average power electrical furnaces for steelmaking, silicon refining, yellow phosphorus refining, etc.

2) Anti-oxidation covered graphite electrode. The surface area of the graphite electrode is covered with an anti-oxidation safety layer to create a safety layer that is both conductive and resistant to high-temperature oxidation, decreasing electrode consumption throughout steelmaking.

3) High-power graphite electrode. It is allowed to utilize graphite electrodes with an existing thickness of 18 ~ 25A/cm2, which is primarily made use of in high-power electrical arc furnaces for steelmaking.

4) Ultra-high power graphite electrode. It is enabled to utilize graphite electrodes with present thickness higher than 25A/cm2. Mostly utilized in ultra-high power steelmaking electrical arc heaters.

Graphite anode kind

It is mainly made from oil coke as resources and coal pitch as binder and is made through calcination, batching, kneading, pressing, roasting, impregnation, graphitization and machining. Typically utilized as conductive anodes for electrolysis tools in the electrochemical market, include:

1) Anode plates for different chemical sectors;

2) Numerous anode poles.

Special graphite

It was generally using high-grade oil coke as basic material, coal pitch or synthetic material as binder, through raw material preparation, batching, massaging, tableting, squashing, re-kneading, molding, several roasting, numerous impregnation, filtration and graphitization, Made by machine processing. Typically utilized in aerospace, electronics, and nuclear market fields. It includes spectrally pure graphite, high pureness, high toughness, high thickness and pyrolytic graphite, etc.

Graphite heat exchanger

An impermeable graphite product for heat exchange made by processing artificial graphite into the required shape and then impregnating and solidifying it with resin. It is a heat exchange equipment processed with artificial impermeable graphite as the base. It is mainly used for heat exchange. Used in the chemical industry, include:

1) Block hole heat exchanger;

2) Radial heat exchanger;

3) Falling film heat exchanger;

4) Tube-type heat exchanger.

Non-standard products

This product refers to various special-shaped graphite products transformed from graphite products through further processing. Including shovel-type anodes, fluorine-making anodes, and various specifications of crucibles, plates, rods, blocks and other special-shaped products.

Impermeable graphite

This product refers to various graphite special-shaped products impregnated and processed with resin and various organic substances, including the base block of the heat exchanger.

Supplier

Graphite-crop corporate HQ is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of Silicon materials, we are high quality silicon supplier. Our Company has a diversified product structure with silicon carbon materials, and other negative materials (graphite materials, etc.). Please feel free to contact us. Or click on the needed products and send us an inquiry: sales@graphite-corp.com