Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Power Up: The Secret Globe of High-Performance Lithium Battery Separators .

(Preparation And Application Of High-Performance Lithium Battery Separators)

We like our gadgets. Phones, laptops, electric cars and trucks– they all need power. That power originates from lithium batteries. However what makes a battery secure and effective? A big component is the separator. Think of it as a small, incredibly important gatekeeper inside your battery. This blog site studies high-performance lithium battery separators. We’ll see what they are, why they matter, exactly how they’re made, where they’re used, and answer typical questions. Allow’s begin.

1. What is a High-Performance Lithium Battery Separator? .

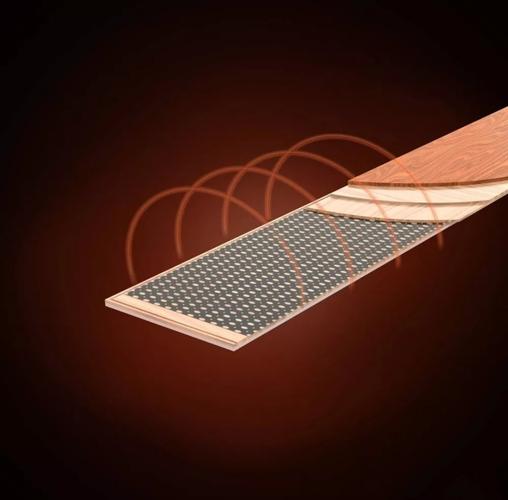

Visualize a battery. Inside, you have a favorable end (the cathode) and an unfavorable end (the anode). They must never touch directly. If they do, bad points take place– short circuits, fires, also explosions. The separator rests right between them. It’s a slim, porous film. Its major job is basic: keep the cathode and anode apart. But it does a lot more.

A high-performance separator isn’t simply any plastic sheet. It’s crafted for quality. It allows lithium ions to move easily backward and forward throughout billing and releasing. That ion circulation is the electrical energy we utilize. At the very same time, it blocks electrons. Electrons taking a shortcut reason shorts. Crucially, it should be strong, stable, and manage warm well. It imitates a safety net. If points get as well warm inside the battery, a superior separator can shut down ion flow. This prevents thermal runaway– a chain reaction leading to fire. So, it’s a physical barrier, an ion freeway, and a safety fuse, done in one ultra-thin layer.

2. Why Do We Need High-Performance Separators? .

Batteries are anywhere. We demand even more power, longer life, faster billing, and absolute safety and security. Requirement separators can fight with these demands. High-performance versions are essential for numerous factors.

Initially, safety is non-negotiable. News stories concerning battery fires are frightening. A weak or flawed separator is commonly the culprit. High-performance separators are harder. They resist tearing and shrinking. They have better thermal security. This means they stand up under anxiety and warmth much better, substantially decreasing fire threats. Second, they increase battery performance. Better separators enable faster ion activity. This equates to quicker charging times. They likewise support higher power density. This suggests more power loaded right into a smaller sized or lighter battery. Think much longer phone life or higher electrical cars and truck variety. Third, they boost battery lifespan. A robust separator holds up against the chemical and physical wear inside a battery longer. This leads to batteries that last even more cost cycles prior to passing away. Without high-performance separators, next-generation batteries for electric cars and advanced electronics just would not be possible or risk-free.

3. Just How Are High-Performance Lithium Battery Separators Made? .

Making these thin movies is a sophisticated process requiring precision. The main material is usually polyolefin, like polyethylene (PE) or polypropylene (PP). Occasionally porcelains or various other finishings are added. Below’s a simplified consider common methods:.

Dry Refine: Believe extending plastic. A polymer resin is thawed and extruded right into a thin film. This movie is then stretched extremely carefully in one direction (uniaxial) or more instructions (biaxial). Extending produces tiny pores. The size and shape of these pores are crucial for ion circulation. This approach is quick and prevents solvents.

Wet Refine: This makes use of liquids. Polymer powder is blended with a fluid plasticizer and various other stuff. This blend is expanded right into a movie. After that, the plasticizer is washed out with an additional solvent. Washing leaves the permeable polymer structure. The movie is then stretched and dried out. This method commonly gives a lot more consistent pore structures yet entails handling chemicals.

Finishings: Commonly, a base separator made by dry or wet process gets an added layer. A typical layer is ceramic bits (like alumina). This ceramic layer is applied to one or both sides. Why? It drastically boosts heat resistance. It stops the separator from reducing too much if things get hot. It additionally makes the separator more powerful and improves electrolyte absorption. Other finishings could add unique shutdown homes or boost attachment.

Quality assurance is constant. Every batch is examined for density, pore size, toughness, warmth resistance, and extra. Tiny flaws can ruin battery performance or safety.

4. Where Are High-Performance Lithium Battery Separators Utilized? .

These aren’t for your fundamental push-button control batteries. High-performance separators are important for demanding applications where failing isn’t a choice:.

Electric Vehicles (EVs): EV batteries are substantial packs consisting of hundreds of cells. They need tremendous power, lengthy array, super-fast charging, and absolute safety and security. High-performance separators, specifically ceramic-coated ones, are common below. They handle the high energy density and warmth produced throughout quick charging and discharging.

Advanced Customer Electronic Devices: Your mobile phone, premium laptop, tablet computer, or drone. We desire them slim, light, powerful, and safe. High-performance separators enable the slim, high-capacity batteries that power these devices dependably. They help stop overheating occurrences.

Power Tools: Cordless drills and saws need bursts of high power. They likewise get knocked around. Separators right here require to be difficult and handle high existing draw consistently.

Energy Storage Equipment (ESS): Large battery banks store solar or wind power for homes or the grid. These systems run constantly and require long lifespans (10-15+ years). High-performance separators make sure stability and longevity over countless cycles.

Medical Gadgets: Implantable gadgets like pacemakers or critical health center tools require entirely reputable power. Battery failing is undesirable. The greatest grade separators are used here for optimum safety and security and efficiency consistency.

Essentially, anywhere you need an effective, safe, and durable lithium battery, particularly if it’s rechargeable, a high-performance separator is likely working within.

5. Frequently Asked Questions About High-Performance Lithium Battery Separators .

Let’s deal with some typical inquiries:.

Q1: Are all battery separators the very same? No. Standard customer batteries could make use of easier, more affordable separators. High-performance batteries (EVs, costs electronic devices) call for sophisticated separators with better products, layers, and tighter quality assurance for superior security and power.

Q2: What’s the greatest advantage of ceramic coatings? Warmth resistance. The ceramic layer imitates armor. It stops the separator from shrinking and thawing also promptly under high warm. This is important for quiting thermal runaway in large or fast-charging batteries.

Q3: Can a poor separator trigger a battery to explode? Yes. If a separator splits, diminishes excessive, melts, or gets punctured (like by lithium dendrites), it can allow the anode and cathode touch. This creates an internal brief circuit, generating intense warm really quick, potentially resulting in thermal runaway and fire/explosion. A high-performance separator is a crucial safety obstacle.

Q4: Do separators affect charging speed? Yes. The separator’s pore structure and material influence just how quickly lithium ions can move. A well-designed high-performance separator allows faster ion circulation, making it possible for quicker charging without harming the battery.

(Preparation And Application Of High-Performance Lithium Battery Separators)

Q5: Exist choices to polyolefin separators? Research is continuous. Products like cellulose, aramid fibers, or advanced composites are being discovered. Some show assurance for also much better thermal security or performance. Nevertheless, polyolefins, frequently with coatings, remain the leading choice for high-performance applications as a result of their proven equilibrium of homes and manufacturability.