Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

PRODUCT PARAMETERS

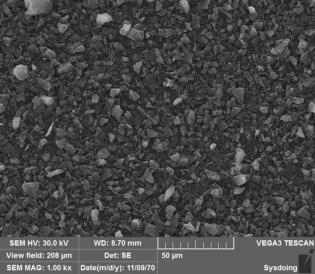

- Product Category: Hard Carbon Anode Materials for Sodium-Ion Batteries

- Features: Made from superior biomass precursors using a unique process, it boasts high specific capacity, excellent first-use efficiency, good rate performance, and exceptional processing properties.

- Applicable to: small-powered vehicles, two-wheeled vehicles, and other fields.

Description

This hard carbon anode material is prepared using selected biomass as a precursor, combined with a unique structural control and carbonization process. It achieves high specific capacity while exhibiting excellent first-time coulombic efficiency and stable electrochemical performance.

The material demonstrates outstanding rate performance, meeting the requirements of frequent start-stop and rapid charge-discharge conditions, and possesses good processing properties, facilitating large-scale fabrication and electrode shaping. With its safety, stability, and cost advantages, this product is highly suitable for battery systems in small electric vehicles and two-wheeled vehicles, providing a cost-effective and sustainable anode material solution for related applications.

key indicators

| number | name | unit | standard | Detection methods and instrument models | |

| 1 | particle size | D10 | um | 2.0~4.0 | Laser particle size analyzer |

| D50 | um | 6.0~8.0 | |||

| D90 | um | 10.0~14.0 | |||

| D100 | um | ≤25.0 | |||

| 2 | Moisture | % | ≤0.5 | moisture meter | |

| 3 | pH | / | 7.0~11.0 | pH 计 | |

| 4 | Ash content | % | ≤0.2 | muffle furnace calcination method | |

| 5 | Tap density | g/cm3 | ≥0.65 | Tap density tester | |

| 6 | compacted density | g/cm3 | 1±0.1 | Compacted density tester | |

| 7 | SSA | m2/g | ≤5 | Surface area meter/static method | |

| 8 | First charge specific capacity | mAh/g | 300±10 | 新威电池测试系统 0.1C/0.1C, 0-2.5 V | |

| 9 | Coulomb efficiency | % | ≥90 | ||

Note: The electrostatic homogenizer formulation is HC:SP: PVDF=92:4:4; if using an aqueous formulation, the recommended electrostatic homogenizer formulation is HC:SP:CMC: SBR=94:2:1.5:2.5.

transportation and storage

(1) The product should be stored in a dry, ventilated environment free of foreign objects.

(2) Handle with care during transportation to avoid damage to the inner plastic bag. Do not place heavy or sharp objects on the carton to avoid damaging the packaging.