The depth summary of Natural graphite development direction

Natural graphite is widely used in refractory materials, heat insulating materials, and high temperature resistant materials due to its excellent electrical conductivity, thermal conductivity, lubricity, and plasticity.In recent years, with the in-depth study of natural graphite, it has been found that natural graphite has great room for development in the preparation of graphene, graphite oxide, expanded graphite, fluorinated graphite, antistatic materials, and as a negative electrode material for lithium ion batteries.

Natural graphite has excellent electrical conductivity and thermal conductivity, generally iron black, metallic luster and low hardness.In addition to this, the graphite flakes are also flexible. The purity of natural graphite ore is generally low, and the fixed carbon content is between 10% and 25%.

Purification is generally carried out by a flotation method, a chemical method, a chloride roasting method, a high temperature method, etc., wherein the flotation method is applied to natural flake graphite.

Chemical methods include acid-base melting and hydrofluoric acid methods.The acid-base melting method utilizes a strong acid, a strong base or other compound to act on impurities in natural graphite to convert it into a water-soluble substance, thereby improving the purity of the graphite.In the chloride roasting method, the graphite powder is doped with a certain amount of reducing agent and chlorine gas is introduced, and the chloride in the gas phase is released from the impurities in the graphite by high temperature conditions.

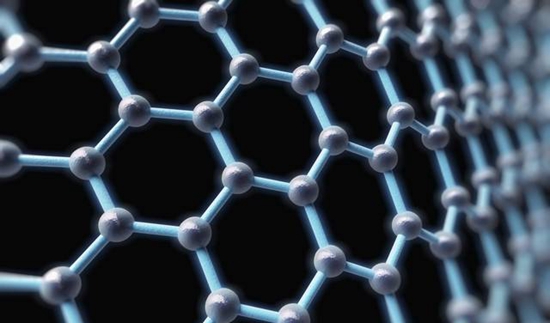

The high temperature method is based on heating and purifying the graphite and the boiling point of the silicate impurities contained therein.The commonly used raw materials are high-carbon graphene containing more than 99% of carbon which has been purified by flotation or chemical method. It is a monolayer of graphite, and the layers are only combined by van der Waals force to form a layered graphite structure.

The carbon atoms in the graphite sheet are bonded by a σ bond and a Π bond, so that the melting point is high and the temperature is high.From the viewpoint of crystallography, graphite can be divided into hexagonal graphite and rhombohedral graphite, with planar hexagons and diamonds as basic structural units, respectively, and the transition energy barrier between the two is small.

Graphite crystals with a diameter of >1 μm are crystalline graphite, and those with a diameter of<1 μm are cryptocrystalline graphite. In general, there is no ideal single graphite crystal, and natural graphite is a mixture of two crystal structures.The development direction of natural graphite is as follows:

1 Preparation of graphene

2 used as a negative electrode material for lithium ion batteries

3 Preparation of expanded graphite

4 nanometer graphite

The negative electrode materials of lithium ion batteries mainly include carbon materials and non-carbon materials. The carbon material anode includes a graphite-based carbon material anode and a non-graphite-based carbon material anode, and the non-carbon material anode includes an alloy anode and a transition metal oxide anode.

Among these negative electrode materials, the use of graphite materials is the most successful. Natural graphite has a high theoretical lithium insertion capacity, low embedding potential and excellent deintercalation function, and is a good anode material for lithium ion batteries.

However, the potential of the graphite electrode is relatively low, which leads to lithium deposition on the graphite electrode. Graphite itself has many reactive groups, resulting in poor compatibility of graphite with solvent, short cycle life of electrodes, and the like.Therefore, it is especially necessary to modify the graphite anode material. The modified graphite mainly includes oxidized graphite, coated graphite, and doped graphite.

High quality graphite manufacturer

If you need graphite powder, please feel free to contact: sales@graphite-corp.com