Single-walled carbon nanotubes VS Multi-walled carbon nanotubes

Carbon atoms can combine in different ways, resulting in many allotropes of carbon with different physical properties. Known allotropes include graphite, diamond, fullerenes, nanotubes, and graphene, most of which are man-made.

When these allotropes of carbon are used as additives, their source, form, and production method can affect the properties of the material, because the different forms of carbon are very different. Graphene and single-walled carbon nanotubes have the best performance combination and advantages.

Except for graphene, these carbon-based additives can be produced on a scale of hundreds or thousands of tonnes and can be used for industrial purposes.

Carbon nanotubes

Carbon nanotubes fall into two categories

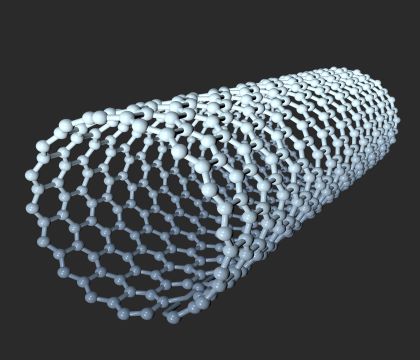

Single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). Although there are obvious commonalities, the physical properties of single-walled carbon nanotubes and multi-walled carbon nanotubes are significantly different due to structural differences.

The most important feature that distinguishes single-walled carbon nanotubes is that they have only one layer of the wall. In other words, single-walled carbon nanotubes can be described as a seamless hollow cylinder formed by rolling up a single layer of the graphene sheet. This is why they are often referred to as monolayer graphene nanotubes.

Unlike single-walled carbon nanotubes, multi-walled carbon nanotubes can be seen as a concentric arrangement of single-walled carbon nanotubes, which consists of multiple layers of graphene sheets seamlessly rolled up into tubes.

These differences between single-walled carbon nanotubes and multi-walled carbon nanotubes lead to great differences in the properties of materials when they are added to the material, and have corresponding effects on the material.

For example, the young's modulus of single-walled carbon nanotubes (sometimes referred to as the elastic modulus related to a material's ability to withstand length changes under stretching or compression) is almost an order of magnitude higher than that of multi-walled carbon nanotubes.

Properties of single-walled carbon nanotubes

1. True nanoscale pipe diameter

The diameter of single-walled carbon nanotubes is less than 2 nm, while the diameter of multi-walled carbon nanotubes is mostly larger than 5 nm and can be up to hundreds of nanometers.

2, long and less defect structure

Both types of carbon nanotubes can grow to a few hundred nanometers or even a few millimeters in length but are typically in the 1-30 micron range.

3. Height-length-diameter ratio (length-diameter ratio)

Due to their small diameter and long length, single-walled carbon nanotubes usually have a high length-diameter ratio, thus providing unprecedented flexibility. Many of the mechanical properties improved by single-walled carbon nanotubes can be attributed to the high aspect ratio.

A THREE-DIMENSIONAL conductive network can be formed at a very low additive amount, starting at 0.01% of the total weight. Such a low addition has little effect on color.

The typical aspect ratio of MWCNTS is low, so the permeability threshold of conductivity is high. Because of their larger diameter, multi-walled carbon nanotubes are very stiff and their asbestos-like properties also pose health risks.

4, elastic

Due to their high rigidity, multi-walled carbon nanotubes are not easy to bend, twist, kink, or buckle without damaging the structure, while single-walled carbon nanotubes are flexible and can more easily restore their original structure.

5, excellent mechanical properties

Single-walled carbon nanotubes have one of the highest tensile strength and elastic modulus of materials (~50 GPa and ~ 1000 GPa, respectively), which are suitable for strengthening a variety of materials, including polymer composites.

Theoretically, the ideal dispersion of single-walled carbon nanotubes with isotropic distribution can be achieved in polymer composites, and the tensile strength can be increased by 100 MPa per addition of 1% (mass ratio) of single-walled carbon nanotubes. In practice, the amount of single-walled carbon nanotubes required to achieve the desired mechanical improvement can be as low as 0.2% (mass ratio).

For multi-walled carbon nanotubes, 3-5% addition is usually required to improve mechanical properties. High addition levels can affect other important features, such as the surface quality and color of the final product.

High quality graphite manufacturer

If you need graphite powder, please feel free to send an email: sales@graphite-corp.com