Can Nano silicon anode greatly increase the capacity of lithium-ion batteries?

With the rapid development of technology, the demand for battery capacity in new energy applications such as electric vehicles and mobile devices is increasing. Nano silicon anode has attracted widespread attention as a high capacity battery material. This article will explore whether nano silicon anodes can improve the capacity of lithium-ion batteries.

Nano silicon anode is an anode material manufactured using nanotechnology, which has high capacity, high conductivity, and good mechanical properties. In lithium-ion batteries, nano silicon anodes can provide higher energy density, thereby achieving longer battery life.

The researchers explained that, when it is charging lithium ions are made to travel from one side (cathode) that is the cathode via an electrolyte solution until they reach the opposite one (anode). Then, when using the battery, the lithium ions return to the cathode and the battery releases current. However, in graphite anodes, storing one lithium ion requires six carbon atoms, so the energy of these batteries is very low.

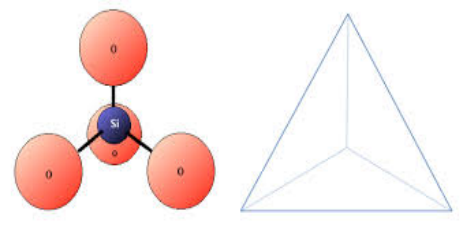

As science and industry explore the use of lithium-ion batteries to power electric vehicles and space shuttles, improving energy density has become increasingly important. Researchers are currently seeking new materials that will enhance the quantity of lithium ions that are stored inside the anode. A very promising option is silicon. It could mix the lithium ions of up to 4 every silicon atom.

Researchers explained that, in the event that the battery gets charged lithium ions are made by force to migrate from one side of the battery (the cathode) via an electrolyte solution to the other (the anode). Then, when the battery is used, the lithium ions return to the cathode, and the battery releases an electric current. In graphite anodes, however, it takes six carbon atoms to store a lithium-ion, so the energy density of these cells is low.

Increasing energy density is becoming increasingly important as science and industry explore the use of lithium-ion batteries to power electric cars and space shuttles. The researchers are currently searching for new materials that could enhance the amount of lithium ions that are stored inside the anode. The most promising option is silicon. It could connect up to four lithium ions in each silicon atom.

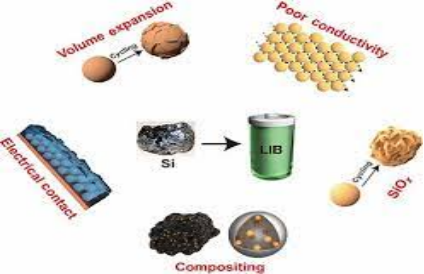

"Silicon anodes can store up to 10 times as much charge in a given volume as graphite anodes and a full order of magnitude more energy density," the researchers said. But the problem is that when lithium ions enter the anode, the volume change is huge, up to about 400 percent, which can cause the electrode to break."

In addition, the large volume change prevents the stable formation of a protective layer between the electrolyte and anode. As s result, this layer has to be modified each time the battery is recharged, which is depleting the amount of lithium ions and reducing the battery's lifetime and its rechargeability.

"Our objective is to attempt to create a stronger anode that can withstand these pressures, and can absorb the maximum amount of lithium and allow the most charging cycles feasible," said Dr. Grammatikopoulos, senior author of the study. The approach we took was to build a structure out of nanoparticles."

In the initial stage, the silicon film appears as a rigid but fragile columnar structure. In the second stage, the pillars touch at the top, forming an arch structure that is strong because of the arch. In the third stage, the silicon atoms are further deposited to form a spongy structure. The red dotted line shows how the silicon deforms when applied.

"The arches are strong, like arches in civil engineering," Dr. Grammatikopoulos said. The same concept applies at the nanoscale."

Importantly, the increase in structural strength also coincides with improvements in battery performance. When the scientists ran electrochemical tests, they found that the charging capacity of the lithium-ion batteries increased. The protective layer is also more stable, which means the battery can withstand more charging cycles.

The discovery of the arch structure and its unique properties is not just an essential step toward the commercialization of silicon-based anodes in lithium-ion batteries. Still, it is also a great opportunity for other applications in the material science field.

"This arch can be used when materials that are strong and can withstand a variety of pressures are needed, such as for biological implants or hydrogen storage," the researchers said. You just need to know the exact type of material, whether it's harder or softer, more elastic or less elastic, and you can do that precisely by simply changing the thickness of the layer, and that's the beauty of nanostructures."

Although nano silicon anodes have high capacity in theory, there are still some challenges in practical applications. For example, the preparation cost of nanosilicon anodes is high, and volume effects may occur during the charging and discharging process, which may result in damage to the internal structure of the battery. In addition, the poor electronic conductivity of nano silicon anodes limits their practical applications.

Nano silicon anode, as a high capacity battery material, has great potential. In order to fully leverage its advantages, it is necessary to address issues such as preparation costs, volume effects, and electronic conductivity. Future research directions can include optimizing the preparation process of nano silicon anodes, researching new structural designs, and researching nanocomposites. With the continuous progress of technology, nano silicon anodes are expected to bring revolutionary breakthroughs to the field of new energy.

High height ion batteries manufacturer

Graphite-corp corporate HQ is a high tech enterprise committed to the research and development, production, processing, sales and technical services of nano silicon anode materials, we are high quality nano silicon anode supplier. Please feel free to contact us. Or click on the needed products and send us an inquiry: sales@graphite-corp.com