Application of carbon nanotubes in the new energy vehicles

From January 1, 2019, the Luoyang region, even the whole Henan region began to restrict motor vehicles for the whole year. The restrictions have been adjusted all the time. However, one thing remains unchanged. The new energy vehicles are not restricted. As the new energy vehicles set off a global sales boom. The people’s attention is attracted by the new energy vehicles.

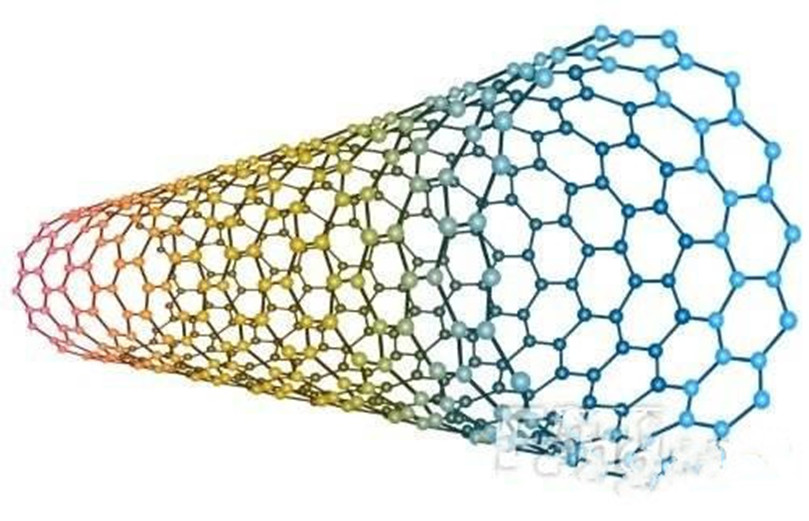

Definition of carbon nanotubes

Carbon nanotube, also known as buckytube, is a one-dimensional quantum material with special structures (the radial size is nanometer, the axial size is micron, and both ends of the tube are sealed). Carbon nanotubes consist of several to dozens of layers of coaxial tubes composed of carbon atoms arranged in a hexagonal pattern. There is a fixed distance between layers, about 0.34nm, the diameter is generally 2~20 nm. The carbon nanotube can be divided into three types: zigzag, armchair and spiral according to the different orientation of carbon hexagon along the axis. The spiral carbon nanotubes are chiral, while the serrated and armchair carbon nanotubes are not. Carbon nanotubes are generally strong. They are always applied for concrete rebar.

Application of carbon nanotubes

Carbon nanotube can be made into a transparent, electrically conductive film which can replace ITO (indium tin oxide) as the material for touch screens. At present, the scientist uses the carbon nanotube powder for match to the solution which can be coated directly onto PET or glass substrates. But the technology is not yet in mass production. Now, the successful mass production is the use of super sequential carbon nanotubes technology.

A composite material with excellent properties can be made by using the properties of carbon nanotubes. For example, plastic reinforced with carbon nanotubes has excellent mechanical properties, good electrical conductivity, corrosion resistance and shielding of radio waves. The carbon nanotube composites made of cement have good impact resistance, anti-static, abrasion resistance and high stability, and are not easy to affect the environment. Carbon nanotubes reinforced ceramic composites have high strength and good impact resistance. Due to the defect of the five-membered ring on the carbon nanotubes, the reactivity is enhanced. In the condition of high temperature and other substances, the carbon nanotubes are easy to open at the end face to form a pipe, which is easy to be infiltrated by metal and form metal matrix composites with metal. Such materials have high strength, high modulus, high-temperature resistance, small coefficient of thermal expansion and strong resistance to thermal change.

Conclusion: While the ultracapacitors have numerous advantages, such as faster charging and discharging. A full charge just need one minute. With long operation life and low loss, it can charge and discharge hundreds of thousands of times. Even in cold and low temperature, the performance of capacitors is not affected. But currently, the energy density of ultracapacitors can not reach the level of lithium-ion batteries. Now the scientific experts are focusing on the development of carbon nanotube supercapacitors. In a few words, a ping-pong ball would spread out over an area the size of a ping-pong ball. But if the ping-pong ball is made of carbon nanotubes, it would spread out over an area the size of a football field. Therefore, using carbon nanotubes to make ultracapacitors can greatly increase the adsorption capacity of ions, that is to say, the energy density of captors increase. But the cost of ultracapacitor is still very high. And there are a lot of technical challenges that need to be overcome.

High quality graphite manufacturer

If you need graphite powder, please feel free to contact: sales@graphite-corp.com