Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Okay, below’s the blog post concentrating on making graphite anodes much better, contacted sound all-natural and specialist.

(Surface Coating Modification Techniques for Graphite Anode Materials)

Surface Area Covering Adjustment Techniques for Graphite Anode Products: Offering Your Battery a More Powerful Heart .

Everybody wants batteries that last much longer, fee faster, and remain safe. Think of your phone passing away prematurely or an electrical car needing constant billing. The key often lies inside the battery itself, especially in the anode material. For years, graphite has actually been the best material for the anode in lithium-ion batteries. It works well, however it has its limitations. That’s where surface area layer adjustment techniques for graphite anode materials come into play. It’s like giving the graphite an unique upgrade, a protective layer that makes it perform better. This blog site dives into what these strategies are, why they matter, how they function, where they’re made use of, and answers some common inquiries.

1. What Are Surface Layer Modification Methods for Graphite Anode Materials? .

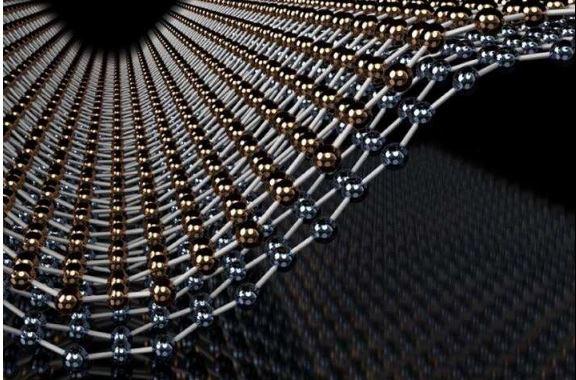

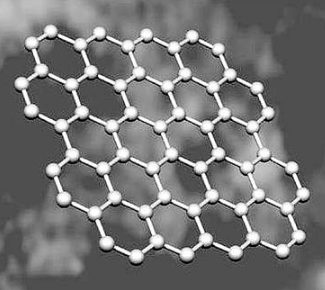

Allow’s break this down. Graphite anode materials are the component inside lots of rechargeable batteries that keep lithium ions when the battery costs. Surface coating modification techniques are methods to alter the extremely external layer of these graphite bits. Think about it like painting or plating something. Scientists use an extremely slim layer of a various material onto the graphite surface. This finish isn’t just a cover. It proactively changes how the graphite acts inside the battery. The finish product can be carbon, steels, steel oxides, and even special polymers. Each kind provides various advantages. The goal is basic: make the graphite job much better and last much longer by tweaking its surface.

2. Why Make Use Of Surface Area Finishing Alteration Techniques for Graphite Anode Products? .

Raw graphite encounters numerous troubles inside a battery. First, it reacts with the fluid electrolyte. This causes a loss of lithium ions right at the start, decreasing the battery’s ability. Second, graphite expands and diminishes a whole lot as lithium ions relocate in and out during billing and releasing. This consistent swelling and shrinking anxieties the product. It chips. It cracks. This subjects fresh graphite surface, causing more undesirable responses and additional lithium loss. Over time, this deterioration means the battery holds much less cost. Third, graphite can sometimes form hazardous lithium metal spikes called dendrites, specifically throughout rapid charging. These can penetrate the separator and trigger fires. Surface finishings tackle these problems head-on. They produce a barrier that secures the graphite. They reduce side responses. They aid the graphite handle growth much better. They can also guide lithium ions to down payment efficiently, preventing dendrites. The result? Batteries last much more cycles, fee much faster safely, and hold more power. Your phone lasts longer. Electric cars go even more. Power tools work harder. It’s a vital upgrade.

3. Exactly How Are Surface Area Coating Adjustment Techniques for Graphite Anode Materials Applied? .

Putting this slim, best coat on small graphite bits needs specific techniques. It’s not like painting a wall surface. A number of strategies prevail. Chemical Vapor Deposition (CVD) is one. Picture cooking the graphite in a special oven filled with certain gases. These gases break down and down payment a slim carbon layer straight onto the graphite surface area. It’s like growing a skin. Atomic Layer Deposition (ALD) is an additional super-precise technique. It functions layer by layer, practically atom by atom. Different chemicals are introduced one after one more. They react just at the surface, building up an ultra-thin, extremely also coating. This is excellent for materials like oxides. Then there’s physical covering. Think of mixing the graphite powder with the layer product in a solution. Techniques like round milling grind them together, requiring the finish material to adhere to the graphite surface. In some cases, the coating material is made independently and after that blended with the graphite. Electrostatic pressures or chemical bonds help them stick. Spray drying or various other drying approaches complete the procedure. The option relies on the finishing product, price, and the exact buildings required. Obtaining an attire, steady layer is key. Any type of weak spots or disproportion decreases the benefit.

4. Applications of Surface Layer Alteration Techniques for Graphite Anode Products .

This modern technology isn’t just lab talk. It’s already making batteries better in many locations. The largest use remains in lithium-ion batteries. These power virtually everything portable: smartphones, laptop computers, tablet computers. Coated graphite anodes help these gadgets last longer on a solitary charge and sustain even more charge cycles. Electric lorries rely heavily on high-performance batteries. Covered graphite anodes contribute considerably. They permit faster billing, which is crucial for EVs. They prolong the driving array by optimizing power storage space. They enhance safety by reducing risks like dendrite growth. Power devices and electric bikes likewise gain from the additional toughness and power. Past customer devices and transport, layered graphite anodes are crucial for power storage systems. These shop power from photovoltaic panels or wind farms. Lengthy life-span and security are essential right here. Layered graphite helps achieve that. Researchers are likewise exploring these finishings for next-generation batteries like sodium-ion or solid-state batteries. The keynote– shielding and boosting the electrode surface area– continues to be powerful throughout different technologies.

5. FAQs About Surface Area Covering Alteration Methods for Graphite Anode Materials .

Does finish graphite make the battery much more pricey? .

It does add price. Procedures like ALD are complicated and slow-moving. But the benefits frequently surpass the expense. Longer battery life suggests less substitutes. Faster charging is a large selling factor. Boosted safety and security lowers risks. Producers function to maximize the layer process and discover cost-effective products. As production ranges up, costs tend to come down.

What’s the most effective finish product? .

There isn’t one single “finest” product. Carbon layers (like amorphous carbon) prevail. They enhance conductivity and safeguard against some responses. Metal oxides (like Al2O3, TiO2) offer excellent security and protection yet may be less conductive. Polymers can be flexible and assist buffer volume adjustments. The option depends on the details battery chemistry and the efficiency objectives. Sometimes, crossbreed finishes integrating products are used.

Does the finishing add weight or use up area? .

The coating is unbelievably thin, typically simply nanometers thick. That’s method thinner than a human hair. So, it adds nearly minimal added weight. It doesn’t occupy significant room inside the battery either. The little bit of added material is a tiny price for the huge efficiency gains.

Can this method solution all graphite troubles? .

It aids a lot, but it’s not a magic fix. Coatings considerably reduce side reactions and boost stability. They aid handle growth. Nonetheless, the core graphite product still has physical restrictions. Really quickly charging or severe conditions can still challenge the battery. Coatings belong to a bigger solution that includes better electrolytes, enhanced cathode materials, and smarter battery administration systems.

Is this only for brand-new batteries, or can old graphite be covered? .

(Surface Coating Modification Techniques for Graphite Anode Materials)

The methods are almost always used during the manufacturing of the graphite anode material. It’s done before the anode is developed into a battery cell. Finish private graphite particles in an existing, utilized battery isn’t functional. The upgrade happens when the battery is made.