Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Unlocking Longevity: Smart Tactics to Boost Sodium Battery Life

(Strategies For Improving The Cycle Life Of Sodium Battery Materials)

Sodium batteries promise a cheaper, more sustainable energy storage future. But keeping them strong through hundreds of charging cycles remains tricky. Let’s explore practical ways scientists and engineers are stretching sodium battery lifespans.

1. What is a Sodium Battery?

Think of it like a cousin to the familiar lithium-ion battery. Instead of scarce lithium, sodium batteries use abundant sodium – yes, the stuff in table salt – as the key shuttle for electrical charge. Inside, sodium ions travel between two electrodes during charging and discharging. This simple swap offers big advantages: lower material costs, reduced reliance on mined minerals, and potentially better safety. But sodium ions are larger and behave differently than lithium ions. This difference creates unique challenges, especially when it comes to how long the battery lasts before fading. The core goal? Make sodium batteries tough enough for daily use in everything from electric cars to grid storage.

2. Why Focus on Sodium Battery Cycle Life?

Cycle life matters. A lot. It tells us how many times you can charge and drain a battery before it loses too much capacity. Imagine buying an electric scooter only to find its range halves within a year. That’s poor cycle life. For sodium batteries to compete with lithium or lead-acid, they need endurance. Long cycle life means:

Lower Cost Per Use: Replacing batteries less often saves money long-term.

Reliability: Devices and vehicles work consistently without sudden power drops.

Sustainability: Fewer dead batteries end up in landfills.

Market Acceptance: Consumers and industries won’t adopt tech that wears out fast. Improving cycle life isn’t just nice; it’s essential for sodium batteries to become a real-world solution.

3. How to Improve Sodium Battery Cycle Life?

Boosting longevity means tackling the weak points. Here are key strategies making waves:

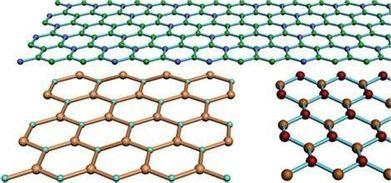

Material Makeover: The electrodes are ground zero. Using hard carbon instead of graphite for the negative electrode handles sodium ions better. For the positive electrode, layered oxides or Prussian blue analogs offer more stable structures. These materials resist cracking and crumbling as ions move in and out.

Electrolyte Engineering: The liquid (or solid) bath ions swim through needs careful tuning. Creating electrolytes that form a super-stable protective layer on the electrodes prevents continuous side reactions eating away capacity. Using special salts and additives helps build this shield.

Interface TLC: The spot where electrodes meet electrolyte is critical. Unwanted chemical buildup here increases resistance and kills batteries faster. Scientists are designing artificial protective coatings and tweaking electrolyte chemistry to keep this interface clean and smooth over thousands of cycles.

Smart Charging: Pushing sodium batteries too hard damages them. Smarter battery management systems use gentler charging speeds, avoid extreme high and low voltages, and maintain optimal temperature. This careful handling reduces internal stress.

Structural Smarts: Designing electrodes with clever structures helps too. Creating nano-sized particles, porous frameworks, or even mixing in flexible binders gives materials room to expand and contract without breaking. Think shock absorbers for ions.

4. Sodium Battery Applications

Where will these longer-lasting sodium batteries shine?

Massive Grid Storage: Storing solar power for night use or wind energy for calm days demands huge, affordable batteries. Sodium’s low cost and improved cycle life make it ideal for power plants and renewable farms needing daily cycling for decades.

Budget-Friendly EVs: Electric cars and scooters need range and durability. Sodium batteries offer a cheaper alternative to lithium, especially for shorter-range city vehicles where daily charging is normal. Long cycle life means the car lasts as long as the body.

Backup Power Systems: Keeping data centers running during outages or powering remote telecom towers requires reliable storage. Sodium batteries provide a cost-effective, safer option than some alternatives for these critical backup roles.

Consumer Electronics: While phones need extreme energy density, larger devices like power tools, home energy storage units, or electric bikes benefit from sodium’s safety and potential for long service life at lower cost.

Emerging Markets: Regions needing basic, reliable energy access can leverage sodium’s abundance. Durable batteries for microgrids or home systems support development without relying on expensive imports.

5. Sodium Battery FAQs

Let’s clear up common questions:

Are sodium batteries ready now? Early versions are hitting markets, especially in China for grid storage and e-bikes. Mass adoption needs more cycle life improvements and large-scale manufacturing.

Are they safer than lithium? Generally, yes. Sodium is less reactive, and many designs use safer electrolytes. They handle heat and overcharging better, reducing fire risk.

How long do they last currently? Top lab cells exceed 5000 cycles. Commercial products aim for 3000-4000 cycles. This competes well with lithium iron phosphate batteries used in storage.

Will they replace lithium batteries? Not entirely. Lithium still rules for high energy density (like laptops). Sodium will likely dominate large-scale storage where cost and cycle life matter most.

(Strategies For Improving The Cycle Life Of Sodium Battery Materials)

What’s the biggest hurdle besides cycle life? Energy density. Sodium batteries store less energy per pound than lithium. Improving density while keeping long life is the ongoing challenge. Progress is steady.