Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Opening Battery Power: Exactly How Material Framework Forms Lithium Efficiency

(Research On The Relationship Between The Structure And Performance Of Lithium Battery Materials)

Lithium battery products are the heart of every rechargeable device. Their hidden style determines if your phone lasts all the time or your electrical automobile goes the extra mile. Neglect boring labs– we’re exploring a tiny universe where atomic setups make or break your battery life.

1. What Are Lithium Battery Materials? .

Lithium battery materials develop the core components inside batteries. They consist of cathodes, anodes, electrolytes, and separators. Cathodes store lithium ions when charging. Typical kinds are lithium cobalt oxide or lithium iron phosphate. Anodes launch ions during usage, often made of graphite. Electrolytes are liquids or gels allowing ions relocate between electrodes. Separators function as safety obstacles avoiding brief circuits.

These materials collaborate during billing and discharging. When you connect in your phone, lithium ions take a trip from cathode to anode. When unplugged, they recede, powering your tool. Tiny adjustments in product dishes impact rate, ability, and safety and security.

2. Why Does Material Structure Matter for Performance? .

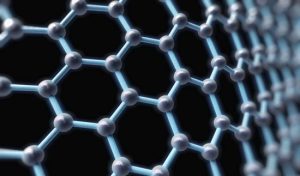

Structure means just how atoms arrange inside materials. Visualize building blocks. Neat heaps let ions relocate openly. Untidy heaps create traffic jams. This impacts 3 vital locations:.

Rate issues. Ions taking a trip faster suggests quicker charging. Phones butt in minutes, not hours. Framework creates freeways or barricades for ions.

Capacity discolors if frameworks fall apart. Repetitive charging strains materials. Splits reduce energy storage space. Much better designs prevent decay, maintaining batteries stronger much longer.

Safety and security risks rise with poor framework. Overheating can cause leaks or fires. Stable atomic layers resist warm, making batteries much safer for electrical automobiles or planes.

3. How Do Scientists Designer Better Structures? .

Researchers modify materials like chefs improving recipes. They use 3 primary approaches:.

Doping adds little contaminations. Believe spraying salt in dough. Adding light weight aluminum to cathodes creates bigger ion paths. Batteries bill much faster without shedding capability.

Covering shields surface areas. A nanometer-thick layer shields electrodes from corrosive electrolytes. Like raincoats for batteries, this avoids decay during severe temperatures.

Nano-shaping develops customized styles. Researchers design porous anodes appearing like sponges. More area implies more ion storage. Believe packing extra shelves in a storage room.

Actual tests show these work. Batteries with silicon nanowire anodes last 400 cycles longer than graphite ones. Fine-tuning frameworks isn’t simply laboratory fun– it upgrades genuine items.

4. Where Do Advanced Lithium Materials Apply? .

Anywhere energy lives. Below’s where framework upgrades radiate:.

Electric lorries need endurance. Batteries with nickel-rich cathodes store 20% more energy. Automobiles drive farther per cost. Secure structures protect against overheating mishaps.

Smartphones yearn for slim power. Ultra-thin batteries utilize compact split cathodes. Phones stay light but run all the time.

Eco-friendly storage counts on durability. Solar farms utilize lithium iron phosphate batteries. Their durable frameworks handle day-to-day charging for years.

Medical gadgets demand security. Pacemakers utilize particularly layered batteries. Also a little leak risks lives. Exact design prevents catastrophes.

5. Frequently Asked Questions on Lithium Battery Materials .

Q: Can much better materials make batteries last forever? .

Regretfully, no. All batteries deteriorate. But improved frameworks sluggish aging. Today’s ideal batteries maintain 80% ability after 2,000 fees.

Q: Why not utilize pure lithium metal? .

Pure lithium responds strongly with air. Dendrites develop throughout charging, puncturing separators. Researchers evaluate lithium-silicon blends– much safer but still experimental.

Q: Are solid-state batteries better? .

Yes. They change fluid electrolytes with solids. This stops leaks and fires. Strong frameworks likewise pack more energy. Expect them in EVs by 2028.

Q: Just how warm is too hot for batteries? .

The majority of stop working above 60 ° C. Warmth loosens atomic bonds. Materials warp, ions reduce. Thermal-stable layouts hold up against desert heat or engine anxiety.

Q: Will we run out of lithium? .

Unlikely. Recycling recovers 95% of battery lithium. New mines open annual. Salt batteries could supplement quickly, reducing lithium need.

(Research On The Relationship Between The Structure And Performance Of Lithium Battery Materials)

Material science never stops. Tomorrow’s batteries might use self-healing frameworks or 3D-printed electrodes. Something’s clear– exactly how we construct at the atomic scale specifies our power future.