Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Okay, here is the rewritten title and the blog post crafted according to your specifications:

(Research And Development Progress Of Silicon-Based Negative Electrode Materials For Sodium Batteries)

Catchy Title: Silicon Shakes Up Sodium Batteries: The Race for Better Power

Blog Post:

1. What Exactly Are Silicon-Based Negative Electrode Materials For Sodium Batteries?

Think about the battery in your phone or laptop. It stores energy using chemicals. Batteries have a positive side and a negative side. The negative side is called the anode. In regular lithium-ion batteries, graphite is a common anode material. Sodium batteries are a newer kind. They use sodium ions instead of lithium ions. Sodium is cheaper and more common than lithium. This makes sodium batteries potentially cheaper and better for large-scale energy storage.

But sodium ions are bigger than lithium ions. Graphite, the usual anode in lithium batteries, doesn’t work well with sodium. Scientists needed a new material. They turned to silicon. Silicon can hold a lot of sodium ions. This means it can store a lot of energy. So, silicon-based negative electrode materials are essentially the anode part made mostly from silicon. They are designed specifically to work well in sodium-ion batteries. The goal is to make batteries that charge faster, last longer, and hold more energy.

2. Why Focus on Silicon for Sodium Battery Anodes? The Big Appeal.

Why are researchers so excited about silicon for sodium batteries? It comes down to a few key reasons. First, silicon promises a massive jump in energy storage capacity. Silicon can theoretically hold much more sodium than traditional carbon materials. This means a battery could be smaller but hold the same energy, or last much longer on a single charge.

Second, silicon is incredibly abundant. It’s one of the most common elements on Earth, found in sand and rocks. This abundance means silicon is cheap and readily available. It helps keep the overall cost of sodium batteries low. Cost is a major factor for widespread use, especially for storing renewable energy or powering electric vehicles.

Third, sodium batteries themselves offer advantages. Sodium is much cheaper and easier to find than lithium. Using silicon anodes could unlock the full potential of sodium batteries. It could make them a real competitor to lithium-ion batteries. This is crucial for building a more sustainable energy future. Lithium resources are limited. Finding alternatives like sodium batteries with high-performance silicon anodes is important.

3. How Are Scientists Making Progress on Silicon Anodes for Sodium?

Developing silicon anodes for sodium batteries isn’t simple. Pure silicon has problems. When it absorbs sodium ions, it swells up a lot. This swelling can break the silicon particles. It also breaks the connections inside the battery. This leads to poor battery life. The silicon surface can also react badly with the battery’s liquid part. This forms a weak protective layer. These issues have slowed down progress.

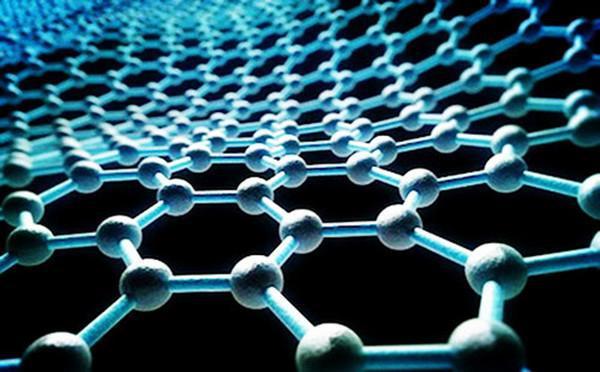

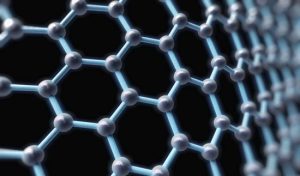

Researchers are tackling these challenges head-on. One major strategy is nano-sizing. Scientists make silicon particles extremely small, like nanoparticles or nanowires. Tiny particles can handle the swelling better. They are less likely to crack. Another approach is combining silicon with carbon. Carbon materials like graphene or carbon black are flexible and conduct electricity well. Mixing silicon with carbon creates composites. The carbon helps buffer the swelling. It also improves electrical connections. This makes the anode material more stable.

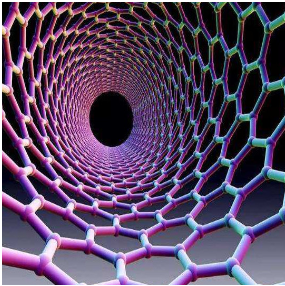

Scientists also work on the silicon surface. They coat silicon particles with special materials. These coatings protect the silicon from unwanted reactions. They help form a better protective layer. This layer is essential for long battery life. Creating special structures is another focus. Designing silicon inside porous carbon frameworks or unique 3D shapes gives the silicon room to expand. This reduces stress and prevents breakdown.

Testing new materials is constant. Researchers try different silicon sources. They experiment with various carbon types. They explore many coating materials. The goal is to find combinations that offer high capacity, long cycle life, and fast charging. Progress is happening. New materials are showing much better performance than just a few years ago. But turning lab success into reliable, mass-produced batteries is the next big hurdle.

4. Where Could These Advanced Sodium Batteries Be Used?

If researchers succeed in making reliable silicon anodes for sodium batteries, the impact could be huge. These batteries could find many important uses. One major area is renewable energy storage. Solar panels and wind turbines generate power intermittently. We need large batteries to store this energy for when the sun isn’t shining or the wind isn’t blowing. Sodium batteries with silicon anodes could be cheaper and have high capacity. This makes them ideal for grid storage.

Electric vehicles (EVs) are another exciting possibility. Today’s EVs mostly use lithium-ion batteries. These are expensive. Sodium batteries with silicon anodes could offer a more affordable option. They could provide longer driving ranges because of silicon’s high capacity. This could help make EVs cheaper and more appealing to more people.

Smaller devices could also benefit. Think about power tools, e-bikes, or even some portable electronics. Batteries that are cheaper, safer, and hold more energy are always desirable. Sodium batteries might not replace lithium in your phone tomorrow. But for power-hungry devices where cost and safety are key, they could be a great fit. Silicon anodes would boost their performance.

Stationary power backup is another application. Homes, businesses, and telecom towers need reliable backup power. Affordable, high-capacity sodium-silicon batteries could be perfect for this. They could provide power during outages. The potential is vast, especially as the world moves towards cleaner energy and electrification.

5. FAQs: Silicon Anodes and Sodium Batteries

Q: Aren’t silicon anodes also being developed for lithium batteries? Why do them for sodium too?

A: Yes, silicon is a hot topic in lithium battery research too. It faces similar challenges like swelling. The push for sodium batteries is strong because sodium is cheaper and more abundant than lithium. Developing silicon anodes for sodium batteries helps create a viable alternative. It diversifies our energy storage options beyond lithium.

Q: How close are we to seeing commercial sodium batteries with silicon anodes?

A: They are not in your local store yet. Progress in the lab is encouraging. Scientists are making materials that work well over hundreds of charge cycles. But moving from lab prototypes to mass production takes time. Companies are starting to explore pilot production. Realistically, widespread commercial availability might still be several years away. More development and testing are needed.

Q: Are sodium batteries with silicon anodes safer than lithium batteries?

A: Potentially, yes. Sodium batteries generally operate at slightly lower voltages than lithium batteries. This can reduce certain safety risks. Also, the materials involved (sodium, silicon, specific salts) can be less reactive than some lithium chemistries. However, safety depends heavily on the exact battery design and chemistry. All batteries need proper safety systems.

Q: Will silicon anodes make sodium batteries charge super fast?

A: Silicon itself doesn’t inherently make charging faster. The speed depends on many factors. These include how well ions move through the material and the battery design. Silicon anodes could enable faster charging if researchers optimize the material structure. For example, nano-sizing silicon and combining it with conductive carbon can improve ion movement. But achieving very fast charging without degrading the battery remains a challenge for both sodium and lithium technologies.

Q: What’s the biggest hurdle left for silicon-sodium anodes?

(Research And Development Progress Of Silicon-Based Negative Electrode Materials For Sodium Batteries)

A: The biggest challenge is achieving long-term stability. Silicon expands a lot when it absorbs sodium ions. This expansion and contraction during charging and discharging puts huge stress on the material. It can cause cracks and breakdown over time. While progress is being made, creating a silicon anode that lasts for thousands of cycles without significant capacity loss is the critical hurdle. Researchers are focused on solving this through material design and engineering.