Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

** Silicide Ceramics: Breaking Obstacles in Extreme Settings **.

(Research And Development Progress Of High-Performance Silicide Ceramics)

Forget regular products. Think of the penalizing problems inside a jet engine, the intense re-entry of a spacecraft, or the intense warmth of next-generation nuclear power plant. Requirement stuff just thaws or shatters. That’s where silicide ceramics step in. These aren’t your average porcelains. They are difficult, unbelievably heat-resistant champions constructed for the most demanding tasks.

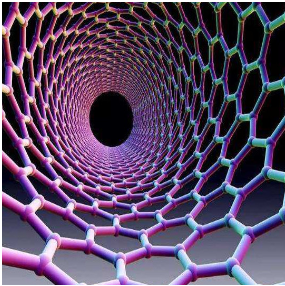

Their secret hinge on the silicon. When silicon bonds firmly with steels like molybdenum, tantalum, or chromium, something special happens. The outcome is a material with a rock-solid framework. This structure pokes fun at blistering temperatures. We’re chatting countless levels Celsius. Steel would certainly be a pool. Numerous ceramics would certainly crumble. Silicide ceramics simply maintain going. They likewise shake off corrosion. Rough chemicals and reactive gases? No worry. This toughness is vital. Assume reducing devices that last ages or heating system parts that make it through brutal cycles.

But raw durability isn’t enough. Early versions can be weak. Imagine a super-strong material that fractures conveniently under anxiety. Not really useful. The genuine progress has actually had to do with making them trusted. Scientists are masters at tweaking the recipe. They add small quantities of various other components. They have fun with how the material kinds. They carefully regulate the grain size inside the ceramic. Think about grains like microscopic blocks. Smaller, more consistent blocks make a more powerful, less crack-prone wall. This is essential for critical parts. Think of turbine blades rotating at outrageous rates. They need to be remarkable.

Making these ceramics is an art also. Traditional approaches often struggled. They could not always attain the perfect thickness or structure required. More recent techniques are altering the game. Stimulate plasma sintering is one interesting technique. It uses extreme warmth and stress in a jiffy. This produces exceptionally dense, near-perfect components much faster. Additive manufacturing, or 3D printing, is likewise signing up with the party. Visualize printing complicated forms layer by layer straight from ceramic powders. This opens doors to styles difficult prior to. Think complex cooling channels inside rocket nozzles or custom heat shields.

(Research And Development Progress Of High-Performance Silicide Ceramics)

The progression is actual. We see silicide ceramics moving from lab curiosities to real-world services. They are discovering homes in aerospace engines. They secure elements in advanced nuclear systems. They make it possible for much more efficient energy production. Every improvement in their strength, their toughness, their manufacturability pushes the borders. It allows designers to create devices that run hotter, quicker, and much longer. This unlocks new opportunities. We can build much better spacecraft, extra powerful jets, cleaner nuclear power plant. The race to overcome extreme atmospheres simply obtained an effective new ally.