Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Trick Needs for Anode Products in Fast-Charging Batteries

(Key Requirements for Anode Materials in Fast-Charging Batteries)

What Are the Trick Needs for Anode Products in Fast-Charging Batteries

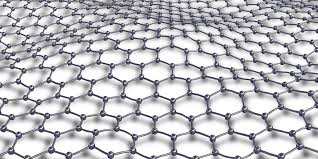

Fast-charging batteries require anode products that can take care of rapid lithium-ion movement without damaging down. The primary job of the anode is to keep lithium ions throughout charging and release them when releasing. For fast charging, this process must happen rapidly and securely. So the anode must have high electrical conductivity to relocate electrons fast. It likewise requires excellent structural stability so it does not break or weaken after several cost cycles. Another key point is reduced volume expansion. When lithium ions get in the anode, the product swells. Way too much swelling reasons damage. That is why materials like graphite are still extensively used. They broaden much less than options like silicon. You can discover more concerning why graphite remains leading in business anodes by visiting this blog site.

Why Do These Needs Issue for Fast Charging

If an anode can not meet these requirements, the battery will certainly bill slowly or stop working early. Slow ion diffusion suggests the battery takes longer to charge. Poor conductivity brings about warmth buildup, which is dangerous. High quantity expansion produces splits. Cracks break electric paths and trap lithium ions. This reduces capability in time. Security is one more large issue. Unsteady anodes can create brief circuits or even fires throughout rapid charging. That is why scientists focus on materials that stabilize rate, safety and security, and longevity. As an example, some permeable carbon products take care of silicon’s growth far better than others. The distinction hinges on their inner framework. Discover why some porous carbons endure silicon development while others fall apart after one usage at this web link.

How Are These Requirements Attained in Real-World Anode Design

Designers utilize numerous methods to satisfy these hard demands. One common technique is finish graphite fragments with carbon or metal oxides to boost conductivity and shield the surface area. One more strategy is blending silicon with graphite. Silicon stores more lithium, however it swells a whole lot. By utilizing percentages of silicon in a graphite matrix, they get higher capacity without way too much development. Some companies likewise make use of prelithiation. This technique adds extra lithium before the battery is made use of. It offsets the lithium lost throughout the first couple of cycles. That aids preserve capacity and boosts cycle life. To understand how prelithiation works and why it matters, look into this in-depth description. Fragment size and shape also play a role. Smaller sized bits reduce the path for lithium ions, quickening billing. However they must be loaded well to avoid throwing away room.

Applications Where These Anode Products Make a Distinction

Fast-charging anodes are important in electrical lorries (EVs). Chauffeurs wish to recharge in minutes, not hours. Without the ideal anode, EV batteries would overheat or wear out quickly. Consumer electronics additionally benefit. Consider smart devices or laptop computers that charge totally in 15 minutes. That just works if the anode can keep up. Power devices and drones require quick ruptureds of energy and fast reenergizing in between uses. Grid storage space systems occasionally call for fast response during peak demand. In all these cases, the anode’s capability to accept lithium promptly and securely specifies performance. Also emerging tech like solid-state batteries relies on suitable anode materials. So the influence of great anode style spreads across many industries.

Frequently Asked Questions Concerning Anode Products in Fast-Charging Batteries

1. Can any kind of anode material be made use of for quick charging?

No. Just products with high ionic and digital conductivity, reduced expansion, and solid structure job well. Graphite is the standard, yet blends with silicon or brand-new carbons are being tested.

2. Why not simply make use of pure silicon anodes?

Silicon holds ten times a lot more lithium than graphite, but it inflates to 300%. This damages the anode after a few cycles. That is why it is utilized in small amounts blended with stable materials.

3. Does fast charging lower battery life?

It can, if the anode is not created for it. Heat and stress and anxiety from rapid ion flow cause wear. Yet with the right anode, fast charging can be done securely for numerous cycles.

4. What is prelithiation and why is it used?

Prelithiation adds lithium to the anode before the very first fee. This replaces lithium lost in side responses during very early cycles. It improves usable capacity and extends life.

5. Exist alternatives to graphite?

Yes, yet none are ideal yet. Tough carbon, titanium-based oxides, and silicon compounds are alternatives. Each has trade-offs in price, energy density, or cycle life. Graphite stays the best equilibrium for many applications today.

6. Just how do makers evaluate anode efficiency for quick charging?

They run charge-discharge cycles at high currents and check temperature level, capacity retention, and architectural modifications. Real-world simulations aid predict lasting habits.

7. Will future batteries remove the need for these strict anode requirements?

(Key Requirements for Anode Materials in Fast-Charging Batteries)

Unlikely. Even with solid electrolytes or new chemistries, the anode must still hold lithium ions successfully. The core difficulties of speed, safety, and resilience will remain.