Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Just How Needle Coke Option Impacts the Quality of Artificial Graphite .

(How Needle Coke Selection Impacts the Quality of Artificial Graphite)

Think of building something absolutely strong and reliable. You require the very best materials. For fabricated graphite, that essential starting point is needle coke. Selecting the appropriate needle coke isn’t just an action in the process. It’s the foundation that establishes exactly how great the final graphite product will certainly be. Obtain it incorrect, and the graphite could split under pressure or break also quickly. Obtain it right, and you create a high-performance material ready for demanding tasks. Allow’s dig into why this selection matters so much.

1. What is Needle Coke? .

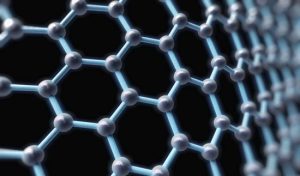

Needle coke is an unique type of petroleum coke. It gets its name from the special needle-like structure of its crystals when you consider it under a microscopic lense. This structure is crucial. It’s not such as normal petroleum coke, which has a much more arbitrary, mosaic-like plan. Needle coke stands out because of exactly how straight and orderly its particles are prepared.

This coke comes primarily from certain types of heavy oil deposits. The oil experiences a process called delayed coking. Here, the heavy oil is heated up to really heats. It breaks down. The lighter parts evaporate and are accumulated. The heavier parts solidify into coke. But only particular oils, refined under very carefully controlled conditions, generate this prized needle coke framework.

The value of needle coke lies entirely because interior structure. Those long, slim, identical crystals are the secret. They are the starting point for making high-grade graphite. This structure provides the raw product the potential to transform right into something exceptional throughout the following actions.

2. Why Does Needle Coke Choice Matter for Artificial Graphite Quality? .

Envision attempting to develop a strong block wall. If your bricks are weak, crunchy, or irregular forms, your wall will not be strong. It could break down. The exact same principle relates to making man-made graphite. Needle coke is the essential ‘brick’ in this procedure. The quality of these ‘blocks’ straight shapes the top quality of the last ‘wall surface’.

Artificial graphite is made via a complicated series of actions. Needle coke is the main ingredient. First, the coke is ground right into powder. Then it’s mixed with a binder, like coal tar pitch. This mixture is formed, typically right into blocks or poles. Following comes baking at heats. This step carbonizes the binder, turning it into solid carbon that holds the coke fragments with each other. Lastly, the baked pieces undergo graphitization. This involves heating them to also greater temperatures, near 3000 ° C. This extreme warmth repositions the carbon atoms right into the ordered layers normal of graphite.

If the needle coke itself has imperfections, these flaws obtain executed every action. They come to be permanent weak points in the graphite. Poor coke selection leads directly to graphite with issues. The graphite might be more likely to damage. It may put on down quicker. It can have irregular electric properties. Or it might respond unexpectedly with chemicals. Picking top notch needle coke avoids these concerns. It makes certain the graphite performs accurately under tough conditions.

3. How to Select the Right Needle Coke? .

Choosing needle coke isn’t about picking any kind of kind. It calls for cautious analysis of certain homes. These buildings predict exactly how well the coke will certainly do during graphite manufacturing and in the final product.

First, consider the physical framework. High-grade needle coke has a distinctive needle-like appearance. You can see this clearly under a microscope. The needles ought to be long, straight, and well-aligned. This placement is vital. It permits the graphite crystals to create correctly later. Stay clear of coke with a mosaic or granular framework. This type won’t create the required graphite properties.

Next off, think about the chemical make-up. Pure coke is much better. Lower degrees of impurities like sulfur, ash, and metals (vanadium, nickel, iron) are crucial. These contaminations don’t graphitize well. They create flaws in the crystal structure. They also hinder the graphitization process itself. Much less pure coke causes graphite that is weaker and less conductive.

The mass thickness of the coke powder matters as well. Higher thickness usually means the coke bits pack together much better. This results in a denser, more powerful graphite product after baking and graphitization. Lower density coke can create a more porous, weak final material.

Ultimately, review exactly how conveniently the coke graphitizes. This is called graphitizability. Great needle coke changes effectively into graphite throughout the high-temperature graphitization action. It establishes the wanted crystalline structure with marginal initiative. Coke with inadequate graphitizability needs extra energy. It may not get to the very same level of perfection. This causes lower-quality graphite.

4. Applications Demanding High-Quality Artificial Graphite .

Artificial graphite isn’t simply any type of product. It’s chosen for jobs where routine products stop working. Its one-of-a-kind buildings make it vital in several requiring areas. The high quality of the graphite, rooted in the needle coke selection, is critical for success in these applications.

Lithium-ion batteries are a significant customer. Inside these batteries, graphite works as the anode material. It shops lithium ions when the battery charges. Premium graphite is needed below. It permits faster charging and discharging. It boosts the battery’s energy storage capability. It also makes the battery last longer with more cost cycles. Poor graphite quality causes shorter battery life and prospective safety issues.

Electric Arc Furnaces (EAFs) in steel manufacturing rely greatly on graphite electrodes. These electrodes carry substantial electric currents to thaw scrap steel. The problems are extreme: intense heat, physical stress and anxiety, and chemical reactions. Only high-grade graphite can manage this. It needs to carry out power efficiently. It should withstand thermal shock from quick temperature modifications. It should not wear down too quickly. The right needle coke ensures the electrode does well and lasts much longer, saving costs.

Specialty graphite finds usages in numerous other locations. High-purity graphite is important in semiconductor manufacturing for making silicon wafers. It’s utilized in gas cells. It’s located in aerospace parts. It’s used in high-temperature heating systems. In all these instances, the graphite should fulfill rigorous requirements for strength, purity, thermal stability, and electrical conductivity. Consistent high quality starts with constant, top-quality needle coke.

5. Frequently Asked Questions on Needle Coke and Artificial Graphite .

People typically have questions regarding needle coke and its function. Below are some usual ones:.

Can other materials replace needle coke for making fabricated graphite? .

Potentially, yes. Products like pitch coke or carbon black are often made use of. However they usually don’t match the performance. Needle coke’s special structure offers graphite superior residential or commercial properties. It gives much better strength, higher thickness, improved conductivity, and longer life-span. For demanding applications, needle coke remains the top selection.

What occurs if low-quality needle coke is made use of? .

Utilizing low-grade coke leads straight to low-grade graphite. The graphite might be fragile and break easily. It might have bad electrical conductivity. It might wear out much quicker in applications like electrodes. Contaminations in the coke can trigger uneven graphitization. This leads to inconsistent efficiency. In general, the end product is less trusted and much less effective.

How does needle coke quality influence battery efficiency? .

In lithium-ion batteries, the anode graphite stores lithium ions. High-quality graphite made from great needle coke allows much more lithium ions to get in and leave promptly. This means faster billing. It additionally means the battery can hold more charge (higher capability). Plus, the structure stays secure over lots of fee cycles, leading to longer battery life. Poor graphite deteriorates quicker, decreasing battery efficiency and life-span.

Is all needle coke the very same? .

No, it differs dramatically. Quality relies on the source oil and the coking process conditions. Different qualities exist. Costs needle coke has extraordinary pureness, high thickness, and exceptional needle structure. Lower qualities have more pollutants or much less excellent framework. Manufacturers carefully select the grade based on the efficiency needs of the last graphite item.

Why is the rate of needle coke commonly high? .

(How Needle Coke Selection Impacts the Quality of Artificial Graphite)

Several factors drive the expense. Producing true needle coke requires certain, often limited, kinds of heavy oil. The coking process requires accurate control and high power input. Cleansing the coke to lower impurities adds more actions and expenditure. Because it’s important for premium graphite used in critical innovations like batteries and steelmaking, need is strong. This mix of specific production and high demand maintains rates raised.