Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Picture cooking a lump of clay. Initially, it’s soft and quickly formed. Warm it carefully, and it solidifies. However cook it at sweltering temperature levels for hours? You obtain something entirely various: difficult, resistant ceramic. Artificial graphite goes through a comparable, dramatic change. Its journey from an easy carbon product to a high-performance marvel hinges entirely on one crucial step: high-temperature graphitization. This intense warm therapy unlocks homes that make artificial graphite essential in our contemporary world, powering whatever from your mobile phone to electric autos and substantial industrial heating systems. Allow’s discover this fascinating procedure.

(How Artificial Graphite Achieves Superior Performance Through High-Temperature Graphitization)

1. What is Artificial Graphite? .

Artificial graphite isn’t extracted from the earth like its all-natural counterpart. We make it. Think of it as carbon, carefully crafted. The trip starts with basic materials abundant in carbon. Oil coke is a typical option. Often, coal tar pitch or other carbon precursors are used. These materials are very first processed right into a strong shape. This could entail mixing, molding, cooking at modest temperature levels, or even extrusion. The outcome is a carbonaceous product. It has some carbon framework, but it’s untidy and incomplete. This intermediate item is called ‘environment-friendly carbon’ or baked carbon. It has some graphite-like high qualities but does not have truth crystalline perfection needed for top performance. It’s the starting block, ready for its metamorphosis.

2. Why High-Temperature Graphitization is Vital .

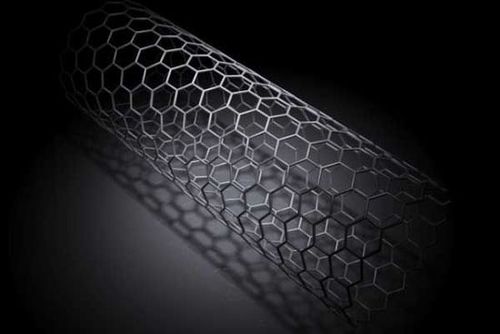

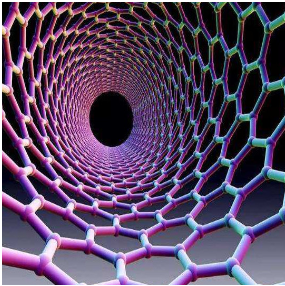

Baked carbon alone isn’t good enough for requiring jobs. Its carbon atoms are jumbled. The framework is disordered, like a heap of blocks instead of a cool wall. This implies it conducts electrical power poorly. It might break conveniently under stress. Warm resistance isn’t ideal. High-temperature graphitization fixes this. It’s the magic heating system that reorganizes whatever. Using extreme warm requires the carbon atoms to relocate. They organize themselves right into organized layers. These layers pile nicely, developing the timeless graphite framework. This transformation is important. It upgrades the material from sub-par to extraordinary. Without this high-heat therapy, synthetic graphite wouldn’t accomplish its trademark buildings: fantastic electrical and thermal conductivity, impressive stamina and lubricity, and exceptional chemical stability. It merely wouldn’t be ‘graphite’ in the true, high-performance sense.

3. Exactly How High-Temperature Graphitization Changes Carbon .

The procedure itself is intense. We take the baked carbon blocks. We put them inside large, specialized furnaces. Believe enormous ovens developed for severe conditions. The temperature inside climbs up exceptionally high. We’re speaking about 2500 to 3000 levels Celsius. That’s hotter than molten lava. This warmth is preserved for a long period of time. It could be days and even weeks. What occurs inside? The harsh warm provides energy. This energy enables carbon atoms to break without their disordered placements. They begin moving. Led by the warm, they arrange themselves into level, hexagonal patterns. These patterns form layers. The layers pile neatly on top of each various other. This creates the particular graphite crystal framework. Consider it like forging steel. The warm reshapes the interior design. It lines up the carbon aircrafts. This placement is the vital to unlocking graphite’s exceptional attributes. The longer and hotter the therapy, generally the much better the crystal positioning and the greater the final top quality. It’s a slow-moving, energy-intensive procedure, however the results deserve it.

4. Applications Leveraging Artificial Graphite’s Performance .

Thanks to graphitization, synthetic graphite stands out where various other materials fail. Its unique residential properties make it essential throughout lots of markets. Lithium-ion batteries are an archetype. Inside your phone or electric vehicle battery, graphite serves as the anode material. Its split framework enables lithium ions to slip in and out easily throughout charging and releasing. This is vital for battery performance and life-span. Electric Arc Furnaces (EAFs) utilized in steelmaking depend greatly on graphite electrodes. These substantial rods conduct massive electric currents to thaw scrap metal. Graphite’s conductivity and capacity to hold up against extreme warm are excellent right here. Factories make use of graphite for molds and crucibles. Its warm resistance protects against contorting when putting molten steel. Chemical plants gain from graphite’s corrosion resistance in heat exchangers and piping. Also day-to-day items like pencils use graphite for lubrication and marking. The high-temperature therapy makes certain the graphite does reliably in these demanding functions. Without graphitization, these applications would not be feasible or efficient.

5. FAQs on Artificial Graphite and Graphitization .

Can’t we just use all-natural graphite? Natural graphite exists. However, its top quality varies significantly. It typically contains impurities. Handling it to the purity and consistency required for high-tech applications is hard and pricey. Fabricated graphite provides exact control over structure and pureness. This makes it much more trusted for essential uses like batteries and electrodes.

Is the graphitization procedure costly? Yes, definitely. Running heating systems at nearly 3000 ° C for days eats substantial amounts of energy. The heaters themselves are complicated and pricey to develop and keep. This adds dramatically to the last rate of top notch man-made graphite. It’s a significant factor in production costs.

Are there different qualities of synthetic graphite? Definitely. The quality depends greatly on the starting products and the graphitization process itself. Elements like the optimum temperature got to and the duration of heating issue substantially. Greater temperature levels and longer times usually produce graphite with better crystal placement, bring about superior electric and thermal buildings. Grades are tailored for specific applications.

What limits the size of graphite items created? The graphitization furnace itself imposes dimension limitations. Manufacturing large, uniform blocks is challenging. Heating such massive items equally throughout to the called for extreme temperatures is practically challenging. This can limit the maximum measurements of electrodes or various other elements made from a solitary piece.

(How Artificial Graphite Achieves Superior Performance Through High-Temperature Graphitization)

Does graphite break? Graphite is durable, yet it isn’t unbreakable. In applications like electrodes, the suggestion gradually wears down due to the intense arc heat and oxidation. In batteries, the graphite framework can break down a little over countless fee cycles. However, the stability achieved via correct graphitization guarantees it lasts far longer than non-graphitized carbon would under the same conditions. It’s developed for endurance.