Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

From Laboratory Grams to Factory Lots: The Difficulties of Product Scale-Up .

(From Lab Grams to Factory Tons: The Challenges of Material Scale-Up)

Visualize baking a best cookie in your kitchen. It tastes remarkable. You decide to make thousands for a big celebration. You face unanticipated issues. Perhaps the stove chefs unevenly. Ingredients act in a different way in huge sets. Your excellent cookie dish needs adjustments. Scaling up materials from the lab to the feels a whole lot like that. It’s a substantial jump. It transforms small scientific research jobs right into big manufacturing difficulties.

1. What is Product Scale-Up? .

Material scale-up is taking a material made effectively busy and creating it in much bigger amounts for commercial use. Consider moving from grams made by a scientist to loads required by a factory. This process involves much more than just making more of the same stuff. It requires changing the whole manufacturing procedure. The techniques used in the small, regulated atmosphere of a laboratory often do not function straight on a huge commercial range. Brand-new tools is normally needed. Various procedure specifications have to be discovered and examined. The goal is to make large batches of the material that match the high quality and homes of the initial small samples. It’s a bridge in between scientific research and manufacturing.

2. Why Scaling Up Products is difficult .

Scaling up materials is tough for numerous key reasons. Initially, processes behave differently at various dimensions. Mixing a small beaker in the lab is basic. Blending a large barrel in a factory is complex. Heat transfer changes. Responses may accelerate or slow down unexpectedly. Contaminations that were minimal in percentages can end up being big problems in big batches. Second, managing quality comes to be much harder. Making one excellent gram is achievable. Making a ton of similar material is much harder. Little variations in resources or procedure conditions can bring about huge distinctions in the end product. Third, economics issue. Procedures that are great in the laboratory might be too slow-moving or too expensive for massive production. Discovering an economical way to make tons is crucial. Fourth, security issues multiply. A small reaction in a laboratory fume hood is workable. The very same reaction happening thousands of times bigger requirements cautious safety and security planning. Scaling up ways dealing with real-world chaos.

3. Just how Do We Range Up Materials Successfully? .

Successfully scaling up products requires a mindful, detailed technique. It seldom takes place over night. It usually entails several phases. Initially, researchers and engineers function very closely together from the start. They make the laboratory procedure with eventual scale-up in mind. They stay clear of excessively complicated steps that will not equate. Next off, they relocate to pilot-scale manufacturing. This is like a middle step. They may produce kilos rather than grams. They use bigger equipment that simulates factory machinery. This stage assists determine troubles early. It allows them to examine different process conditions and fine-tune techniques. They accumulate lots of information. They consider exactly how the material’s buildings transform. They look for uniformity batch-to-batch. After pilot-scale success, the procedure transfers to major manufacturing. Designers develop the factory setup based upon the pilot results. They select the right huge devices. They compose comprehensive treatments. They train operators. Continuous monitoring is important. Even after full production begins, adjustments are often needed. The team must prepare to fix new problems that appear just when making tons.

4. Where Do We See Material Scale-Up Obstacles? .

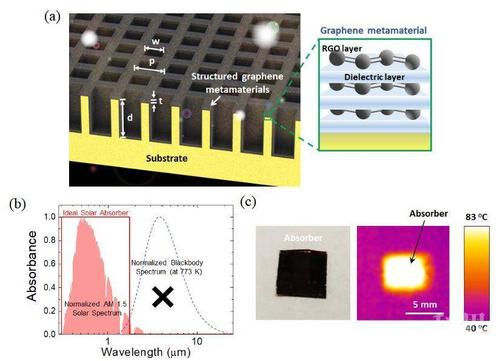

Product scale-up challenges appear across many advanced industries. The pharmaceutical sector continuously handles it. Developing a brand-new medication includes making small amounts for screening. Later on, they require to generate massive quantities reliably and safely. Any kind of modification in the medicine’s crystal structure or pureness during scale-up can impact its effectiveness. The battery market encounters large scale-up difficulties. New battery materials reveal promise in small lab cells. Scaling production to meet electric car demands is a huge task. Keeping efficiency and power density at the lot level is challenging. Nanomaterials are another area. Making one-of-a-kind nanoparticles in the lab is one point. Producing them constantly in big volumes for use in coverings or electronics is another difficulty entirely. Advanced composites used in aerospace or automotive industries additionally require careful scale-up. The materials and fibers need to perform perfectly each time, even when generated in enormous amounts. Also in the food industry, scaling up brand-new healthy protein sources or additives offers similar hurdles. The core issue continues to be the same: moving from regulated small sets to reliable large-scale manufacturing without losing quality.

5. Typical Concerns Regarding Product Scale-Up .

People often ask inquiries concerning material scale-up. Right here are response to some regular ones.

Why can’t we just utilize bigger versions of the lab tools? Occasionally you can, but often you can not. Laboratory equipment is developed for accuracy and flexibility. Factory equipment prioritizes effectiveness, price, and dependability. The physics of procedures like blending or warming adjustment with dimension. Bigger equipment may function in a different way. You generally need specialized industrial machinery.

The length of time does material scale-up generally take? There’s no fixed time. It depends heavily on the complexity of the material and the process. Simple products could scale up in months. Complex ones, like unique drugs or sophisticated batteries, can take several years. Pilot studies and repairing take time.

What’s the biggest risk during scale-up? Consistency is a significant threat. Making product that doesn’t match the lab sample’s residential properties prevails. This can take place as a result of unanticipated process changes or product variations. Stopping working to fulfill quality targets is a large setback.

Just how much does scale-up expense? Costs vary a great deal. Pilot plants need considerable financial investment. Designing and developing full-scale assembly line costs much more. Failed sets or delays add to the expenditure. It’s a significant monetary dedication for any kind of firm.

(From Lab Grams to Factory Tons: The Challenges of Material Scale-Up)

Can computer system simulations assist with scale-up? Yes, significantly. Versions can predict just how procedures could behave at bigger scales. They aid identify prospective troubles prior to constructing costly devices. However simulations are overviews. Real-world testing is still crucial. You require both tools.