Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

** Silicide Shield: Just How Tiny Shields Supercharge Our Technology **.

(Development And Application Of Silicide Coating Technology)

Ever before question how jet engines endure scorching warm? Or why your phone does not melt in your pocket throughout heavy usage? In some cases, the ace in the hole is unseen. Think about non-stick frying pans. That glossy finish stops food from burning. Now envision something comparable, however way tougher, safeguarding essential parts inside devices pushing their limitations. That’s where silicide finishes action in. They’re like microscopic armor plating.

So, what are they? Silicides are substances made by blending silicon with metals like chromium, molybdenum, or titanium. They develop exceptionally hard, steady layers. Heat doesn’t faze them much. Rust battles to bite via. They poke fun at damage. Think of it as giving metal surfaces a superhero upgrade. This isn’t just lab things. It’s a real-world shield for critical components.

How do we get this super-coating onto parts? Scientists and designers got clever. They developed unique methods. One popular means is pack cementation. It seems complex, yet the concept is easy. You surround the steel part requiring protection with a powder mix including silicon and other elements. Then you bake the entire thing in a heater. The heat functions magic. Silicon atoms vaporize and permeate right into the metal’s surface area. They respond, forming that hard silicide layer right where it’s required. It bonds firmly, entering into the component itself. Other approaches exist as well, like spraying molten material or using chemical vapors directly. The objective is constantly the exact same: develop that perfect, resilient guard.

Where does this silicide shield turn up? Almost everywhere demanding efficiency fulfills punishment. Aerospace is a substantial customer. Turbine blades inside jet engines encounter extreme temperature levels and pressure. Silicide coatings act like a thermal obstacle. They keep the underlying metal cooler, letting the engine run hotter and more successfully. This implies far better gas economic situation and even more power. Rockets heading to space advantage too. Their components encounter brutal problems during launch and re-entry.

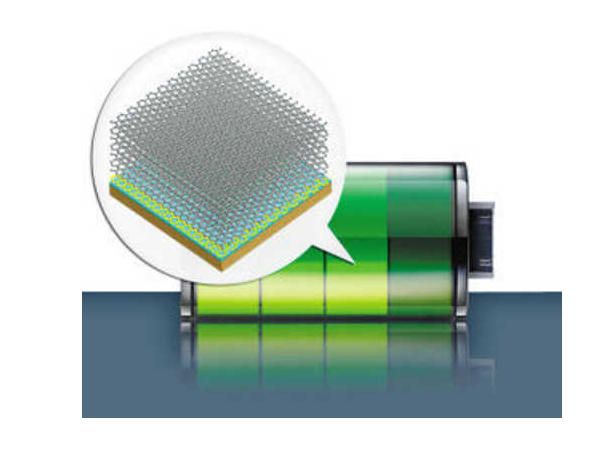

It’s not almost flying high. Power plants depend on silicide finishings. Gas wind turbines producing electrical power run under intense warm. The coatings protect essential parts, expanding their life and minimizing costly downtime. Even the tiny world of electronics gets an increase. Silicide layers help take care of heat in effective computer chips. They stop overheating that can fry delicate circuits. This maintains your devices running smoothly.

(Development And Application Of Silicide Coating Technology)

The story of silicide finishings is about resolving challenging issues. Materials fall short under tension. Warmth, rubbing, and chemical attack take their toll. Silicide modern technology uses a powerful solution. It’s the science of putting a virtually unnoticeable, incredibly resistant skin on steels. This tiny shield allows devices function harder, last longer, and perform accomplishments once believed impossible. Next time you fly or flick on a light, keep in mind the hidden silicide armor making it feasible. It’s a silent change in product scientific research, occurring right on the surface.