Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

1.Introduction to the synthesis process of hard carbon

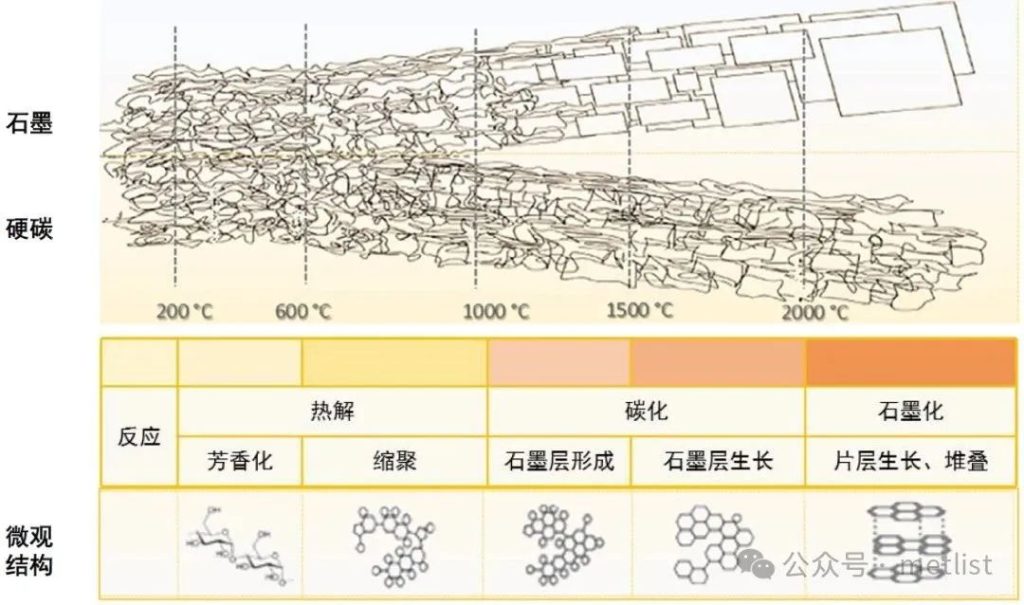

Unlike the synthesis of graphite, a lithium-ion anode material, hard carbon synthesis requires a series of processes, including aromatization, polycondensation, graphite layer formation, graphite layer growth, and finally, sheet growth and stacking.

Artificial graphite is primarily made from chemical raw materials such as needle coke, petroleum coke, and asphalt. These raw materials can melt over a wide temperature range during the carbonization process, allowing the carbon layers to rearrange and form a long-range, ordered sheet structure.

The organic precursors used in hard carbon often contain branched structures containing oxygen, sulfur, and nitrogen groups. During carbonization, these cross-links form a new network structure, which hinders the rearrangement of the carbon layers and prevents the formation of long-range ordered graphite sheets.

The precursor raw materials used in hard carbon are primarily biomass, resins, and polymer precursors.

2.Various process routes for hard carbon

Currently, commonly used hard carbon precursors are primarily bio-based polymers, such as bamboo, coconut shells, starch, and walnut shells. Chemical raw materials such as anthracite, asphalt, and phenolic resins can also be used.

Hard carbon products derived from different precursors exhibit significant performance differences, and the cost structure also varies significantly depending on the raw material source.

Multiple hard carbon processes are being developed in parallel, with anode companies each showcasing their strengths.

Japan’s Kuraray uses coconut shells as a biomass material as its hard carbon precursor. Traditional Chinese lithium battery anode companies like BTR, Shanshan, Zhongke Xingcheng, and Xiangfenghua utilize hard carbon anode processes that incorporate bio-based materials, resin-based raw materials, and asphalt-based raw materials, achieving a systematic patent portfolio.

As a hard carbon anode company competing with Kuraray, Bestec specializes in producing hard carbon materials from biomass materials such as glucose, starch, lignin, and coconut shells. Yuanli Co., Ltd. uses raw materials such as bamboo, coconut shells, and rice husks. Shengquan Group uses straw.

Wuhan Bishidi uses phenolic resin as a precursor.

3.Comparison of hard carbon precursor process routes of different companies

The hard carbon anode process developed by Japan’s Kuraray is relatively complex. It uses coconut shells as raw material and undergoes carbonization, crushing, alkaline treatment, heat treatment, purification, and CVD treatment, with the CVD process being the most challenging.

The domestic company Bester’s hard carbon products use biomass materials such as starch as raw materials. Through modification, cracking and polycondensation, carbonization, and surface modification, they produce sodium ion hard carbon materials that meet fast-charging performance requirements. This company’s product process is simpler and more cost-effective than that of international companies, with a price tag of approximately half that of overseas competitors.

According to publicly available patent information from Shanshan Technology and BTR, hard carbon processes for both asphalt-based and resin-based materials have been developed.

4.Comparison of the advantages and disadvantages of mainstream hard carbon precursors

Coconut shell biomass materials are one of the earliest industrialized hard carbon precursors. This type of material is widely present in nature, has few impurities, and has relatively high strength, which can bring a stable structure to hard carbon products. However, the current domestic supply of coconut shell raw materials to meet the production of hard carbon negative electrodes is insufficient and needs to rely on imports.

Polysaccharide biomass materials such as starch are widely available, inexpensive, and can be naturally degraded, giving them an advantage in terms of environmental protection. The main problem at present is the high process cost, which requires the addition of additives such as cross-linking agents or hydrogenation modification.

The hard carbon products obtained from phenolic resin precursors have good uniformity and high purity. The products are generally spherical particles. Because the raw materials are controllable, the process design is strong, but the disadvantage is that the cost is high.

Asphalt-based materials are widely available and inexpensive. Both coal-based asphalt and oil-based asphalt can be used. However, the disadvantage is that the asphalt contains a lot of volatile matter, requiring additional exhaust gas treatment, which increases costs. In addition, the current process is not mature and the product capacity is low.

5.Biomass-based precursors have moderate performance and a wide range of material sources

The raw materials for the biomass-based hard carbon negative electrode route come from various sources, such as walnut shells, fruit shells, grapefruit peels, animal and plant tissues, etc. From the perspective of the three technical routes of biomass-based, phenolic resin-based, and asphalt-based, the hard carbon produced by the biomass-based route has moderate performance, a wide range of material sources, and relatively appropriate costs. It is currently the choice of major production companies.

Hard carbon anodes using different biomass materials as precursors require different carbonization temperatures, and the resulting anode materials also have significantly different first-cycle coulombic efficiencies.

Synthetic polymer precursors offer superior performance but are expensive. These primarily include chemically synthesized materials like phenolic resins and polyacrylonitrile. Comparing the performance of current technology routes, the synthetic polymer precursor route offers superior performance, including specific capacity and coulombic efficiency. However, synthetic polymers are more expensive than biomass-based and fossil fuel-based routes.

Fossil fuel-based precursors are inexpensive but offer lower performance. These primarily include asphalt, coal tar, and related mixtures. Comparing the performance of current technology routes, the fossil fuel-based precursor route offers lower costs, but performance, including specific capacity, rate capability, and coulombic efficiency, is lower than the other two routes.

Biomass-based hard carbon anodes have outstanding profitability and are the primary direction for future hard carbon precursors. The core barrier to maintaining a high gross profit margin lies in a stable and large-scale biomass raw material source and advanced processing technology.