Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Artificial graphite requires four major processes and more than ten minor processes.

Artificial graphite aggregates are divided into three main categories: coal-based, petroleum-based, and a mixture of coal and petroleum. Among these, coal-based needle coke, petroleum-based needle coke, and petroleum coke are the most widely used. Generally, high-capacity anodes use needle coke as the raw material, while ordinary capacity anodes use the cheaper petroleum coke. Pitch is used as a binder.

Artificial graphite is manufactured by crushing, granulating, graphitizing, and screening aggregates and binders. The basic process flow is consistent, but the specific preparation process varies somewhat from one company to another.

The production process we have outlined and summarized is generally as follows:

(1) Preprocessing

Depending on the product, graphite raw materials are mixed with asphalt in varying proportions, with a mixing ratio of 100:(5~20). The materials are transferred to a hopper using a vacuum feeder and then fed into an air jet mill for grinding. The raw materials with a particle size of 5-10 mm are ground to 5-10 micrometres. After air jet milling, the desired particle size material is collected using a cyclone dust collector, with a collection efficiency of approximately 80%. The exhaust gas is filtered by a cartridge filter before being discharged, with a dust removal efficiency greater than 99%. The filter cartridge is made of filter cloth with pores smaller than 0.2 micrometres, which can intercept all dust particles larger than 0.2 micrometres. A fan controls the entire system to maintain a negative pressure.

(2) Granulation

The granulation process consists of a pyrolysis step and a ball milling and screening step.

Pyrolysis process: Intermediate material 1 is fed into the reactor. The air in the reactor is purged with N2, and the reactor is sealed. Under a pressure of 2.5 kg, the reactor is electrically heated according to a temperature curve, stirred at 200-300°C for 1-3 hours, and then further heated to 400-500°C with stirring to obtain a material with a particle size of 10-20 mm. After cooling, the material is discharged, resulting in intermediate material 2. Volatile gases from the reactor are extracted by a fan, condensed in a condenser, and the liquid condenses into a tar-like substance. The gaseous waste is drawn out by a fan, filtered through activated carbon, and then discharged.

Ball Milling and Sieving Process: Vacuum feeding is used to transport intermediate material 2 to the ball mill for mechanical grinding, reducing the 10-20 mm material to a particle size of 6-10 micrometres. The resulting powder is transported via pipeline to a sieving machine for screening. The undersized material is measured and packaged using an automatic packaging and metering device to obtain intermediate material 3. The oversize material is returned to the ball mill via a vacuum pipeline for further grinding. The ball milling and sieving processes are completely enclosed, and the material is transported using a vacuum. The air and material are separated by air jet vibration. The dust-laden exhaust gas after air-material separation is filtered through a filter cartridge before being discharged from the workshop.

(3) Outsourced graphitization

The graphitization process is handled through outsourcing, with intermediate material 3 being sent to a nearby carbon plant for graphitization processing.

(4) Ball milling and sieving

The graphitized material is transported to a ball mill via a vacuum conveyor for physical mixing and ball milling. It is then sieved using a 270-mesh molecular sieve. The sieved material is inspected, measured, packaged, and stored. The material retained on the sieve is further ball-milled until it meets the required particle size before being sieved again. As can be seen, the process from raw coke to the final lithium-ion battery anode material involves four major process steps (crushing, granulation, graphitization, and sieving), which can be further subdivided into more than ten smaller steps. The overall preparation process is very lengthy.

The granulation and graphitization stages represent technological barriers.

Among the four main processes of artificial graphite production, crushing and screening are relatively simple. The technical barriers and production capabilities of companies in the anode material industry are primarily reflected in the granulation and graphitization stages.

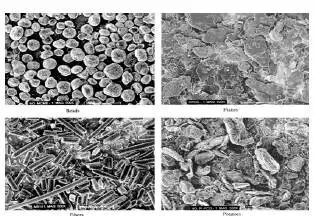

Granulation: The size, distribution, and morphology of graphite particles affect multiple performance indicators of the anode material. Generally, smaller particles lead to better rate performance and cycle life, but poorer initial efficiency and tap density, and vice versa. A reasonable particle size distribution (mixing large and small particles) can improve the specific capacity of the anode; the particle morphology also has a significant impact on rate performance and low-temperature performance.

Therefore, anode manufacturers need to possess the ability to design and control particle size and morphology in order to achieve the desired performance indicators.

Graphitization is another crucial step in the production of artificial graphite. This process transforms the carbon atoms from a thermodynamically unstable “two-dimensional disordered overlapping” arrangement to a “three-dimensional ordered overlapping” arrangement.

The most commonly used graphitization furnace in artificial graphite production is the Acheson graphitization furnace. The problem with the Acheson furnace is that it easily leads to uneven temperature distribution and thermal stress. When the furnace temperature rises rapidly, a significant temperature difference between the outer and inner parts can occur, resulting in cracks and defective products. Another type of graphitization furnace that has emerged in recent years, the internal series furnace, also has considerable problems. (For example, it easily causes graphite powder to detach from the crucible, introducing impurities and dust, and the volatile substances produced during the graphitization process are not easily discharged, leading to low purity.)

To achieve better graphitization results, anode manufacturers need to focus on the following aspects:

1. Mastering the methods of loading resistive materials and other materials into the furnace (including horizontal loading, vertical loading, staggered loading, and mixed loading), and adjusting the distance between materials based on the properties of the resistive materials;

2. Using different power curves to control the heating and cooling rates during the graphitization process, depending on the capacity of the graphitization furnace and product specifications;

3. In specific cases, adding catalysts to the material mixture to improve the degree of graphitization, i.e., “catalytic graphitization.”

In addition, the selection and proportioning of raw materials (petroleum coke, needle coke, and binder) are also a core technology for the negative electrode.