Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Hot Stuff: How Silicides Are Powering Up Thermoelectric Technology .

(Application Research Of Silicides In Thermoelectric Devices)

Bear in mind those old sci-fi flicks where spacecrafs ran on warmth? That future is closer than you think, thanks partially to products called silicides. They’re silently coming to be the secret sauce inside thermoelectric devices, turning waste heat directly into power. Allow’s study why these substances are triggering such a stir.

1. What Exactly Are Silicides? .

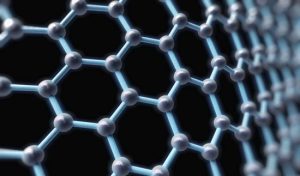

Consider silicides as an unique club where silicon meets metal. They create when silicon atoms bond securely with atoms from metals like magnesium, iron, or cobalt. This isn’t simply a laid-back relationship; it’s a strong chemical bond. The outcome? Materials that typically look metallic, perform electrical energy quite well, and can handle significant warmth without breaking down. Picture them as tough, heat-resistant hybrids. They’re not brand-new– silicides have been used for years in things like integrated circuit. Now, scientists are unlocking their possibility for a different work: ordering warm and transforming it right into power.

2. Why Silicides Rock for Thermoelectric Jobs .

Thermoelectric gadgets are great. They make electrical energy from temperature level distinctions– no moving components, just pure physics. But they need special products. Great thermoelectric things needs to do 3 things well: conduct electrical power like a champ, block warm like an insulator (so the temperature level difference remains solid), and create a good voltage when heated. This trio is difficult to discover. Silicides tip up. Lots of silicides normally have low thermal conductivity. Heat battles to move via them easily. That’s half the battle won. And also, we can modify their electrical homes. Researchers include tiny quantities of other aspects or play with their framework to make them much better at shuttling electrons. They’re also challenging cookies. Silicides deal with heats far better than several elegant, more recent thermoelectric products. They don’t thaw or degrade conveniently. This ruggedness matters for real-world usage near engines or heating systems. Lastly, they’re made from typical stuff. Silicon and several partner metals are bountiful and less costly than uncommon aspects like tellurium frequently utilized somewhere else. This makes silicide-based tools potentially much more inexpensive and scalable.

3. Exactly How Silicides Get Into Thermoelectric Devices .

So, just how do we in fact make use of these silicides? It begins with making the ideal things. Researchers prepare silicide powders utilizing approaches like melting aspects together or very carefully reacting them in solid state. Getting the specific recipe is essential. Next off, we require solid items. The powder gets squashed and warmed under high stress in a process called sintering. This makes a thick chunk, like a small tile. This tile is the thermoelectric material. Currently, visualize 2 various ceramic tiles: one “p-type” (good with favorable charge service providers) and one “n-type” (great with adverse cost carriers). We generally make the n-type leg from a silicide like magnesium silicide (Mg two Si) or higher manganese silicide (HMS). The p-type leg could be one more silicide or a different product. These two legs get linked electrically in series yet thermally in parallel. One end fumes (say, near an exhaust pipeline), the various other end remains cool. This temperature difference makes electrons flow with the n-leg and openings circulation via the p-leg, producing an electrical present. Engineers construct most of these pairs right into components for more power. Safeguarding the whole point from oxidation at high warm is critical, typically with unique coverings.

4. Where Silicide Thermoelectrics Are Making Heat (and Power) .

Silicides aren’t just lab inquisitiveness any longer. They’re finding actual tasks. One big target is your cars and truck. Visualize catching the warmth lost in the exhaust pipe and utilizing it to power the radio, lights, and even help charge the battery. That improves gas effectiveness. Silicides, specifically magnesium silicide, are strong candidates right here since they take care of the exhaust warm range well. Manufacturing facilities are an additional hotspot. Industrial refines blast out huge quantities of waste heat. Silicide modules could use this, generating power right on-site to reduce energy bills. Assume heating systems, kilns, or power plants. Also area expedition benefits. Area probes need trustworthy, resilient source of power much from the sun. Radioisotope thermoelectric generators (RTGs) convert warmth from decaying nuclear material right into electricity. Silicides can make these RTGs extra effective or long lasting for deep room missions. Smaller-scale usages are appearing too. Assume wearable sensing units powered by your body heat or systems maintaining satellite electronics warm using their own waste warm. Silicides supply a sturdy, possibly cost-effective course for these specific niche applications.

5. Silicides in Thermoelectrics: Your Inquiries Addressed .

Let’s deal with some typical questions concerning silicides and thermoelectric gadgets.

Are silicide tools the best? They might not defeat the outright peak efficiency documents of some exotic products yet . But they offer an excellent equilibrium: good performance, superb strength, high-temperature security, and reduced cost possibility. For numerous tough, warm settings, they’re usually the useful best option.

What’s the greatest challenge? Making p-type silicides comparable to the n-types has been complicated. Discovering silicides that function just as well for both legs streamlines module layout. Researchers are striving on this, discovering brand-new silicide make-ups and tweaks.

Are they risk-free? Normally, yes. Silicides made use of in thermoelectrics (like Mg ₂ Si, MnSi) are steady solids. They don’t posture significant poisoning threats like some lead or tellurium substances can. Taking care of fine powders requires care, as always, however the bulk materials are secure.

Why aren’t they anywhere currently? Scaling up manufacturing of top notch silicide products dependably and cost effectively requires time. Incorporating them perfectly into components and systems is likewise ongoing job. The technology is maturing quickly, moving from laboratories to pilot tasks and early industrial use.

(Application Research Of Silicides In Thermoelectric Devices)

What’s next? Expect more development! Research study concentrates on improving effectiveness further with nanostructuring (making little attributes inside the material to block warm better), finding new silicide compounds, enhancing production approaches, and creating far better modules particularly for silicides. The goal is cheaper, a lot more efficient tools catching waste warmth almost everywhere.