Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Shining Light on Silicates: The Secret Heroes in Optical Glass

(Application Research Of Silicates In Optical Glass)

Ever wonder how your camera lens captures such sharp images, or how telescopes see billions of light-years into space? The answer often lies hidden inside the glass itself. Silicates, those common compounds built from silicon and oxygen, are the quiet champions making it all possible. Forget boring lab reports; let’s uncover the fascinating role silicates play in crafting the super-clear, super-precise glass we rely on every day.

1. What Exactly Are Silicates in Optical Glass?

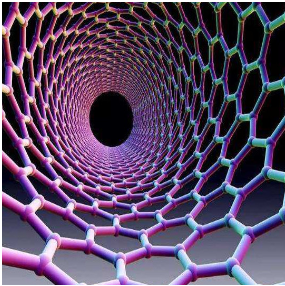

Think of silicates as the fundamental building blocks. Chemically, they are compounds made mainly of silicon (Si) and oxygen (O), often combined with other elements like sodium, potassium, calcium, aluminum, or boron. In the world of glass, especially optical glass, they form the primary network of the material. Picture a complex, three-dimensional web. Silica (SiO2), the simplest silicate, is the core structure. But pure silica glass is hard to melt and shape. This is where other silicates come in. Materials like soda ash (sodium carbonate) or potash (potassium carbonate) are added. They react with silica to form different silicate structures – sodium silicates, calcium silicates, etc. These additions fundamentally change the glass’s properties. They lower the melting point, making the glass easier to work with. They also influence critical optical characteristics like how much the glass bends light (refractive index) and how it spreads out different colors (dispersion). Essentially, silicates are the glass skeleton. The specific types and amounts chosen determine the glass’s final personality – its clarity, strength, and how it interacts with light.

2. Why Are Silicates So Crucial for Optical Glass?

Optical glass isn’t just any clear material. It needs extreme precision. It must bend light rays in predictable ways to form perfect images. Silicates deliver this precision in several key ways. First, they provide incredible chemical stability. Silicate-based glass resists attack from water, acids, and the environment. This stability is vital for lenses and prisms that must last for decades without degrading. Second, silicates allow glassmakers to fine-tune the glass’s optical properties with incredible accuracy. By changing the silicate recipe – adding more of one element, less of another – engineers can precisely control the refractive index and dispersion. This is how different types of optical glass are created, each designed for a specific role in a complex lens system. Third, silicates contribute to the exceptional homogeneity (uniformity) required. Any tiny bubbles, streaks, or variations in composition would distort the light passing through. The chemistry of silicate melting, when done right, allows for a highly uniform melt that solidifies into flawlessly clear glass. Without silicates achieving this level of control, consistency, and stability simply wouldn’t be possible. High-performance optics would be a dream.

3. How Do We Use Silicates to Make High-Quality Optical Glass?

Turning raw silicates into perfect optical glass is a careful art and science. It starts with selecting the purest raw materials: high-grade quartz sand (SiO2), carbonates, oxides. These are weighed precisely according to a secret recipe designed for the desired glass type. The materials are mixed thoroughly. This mixture, called the batch, is fed into a high-temperature furnace. Temperatures soar above 1500°C (2700°F), melting the batch into a bubbling, glowing liquid. Here, the silicate magic happens. Chemical reactions transform the mix into a uniform melt dominated by complex silicate structures. But the melt isn’t perfect yet. Gases bubble up, and impurities might remain. The molten glass undergoes fining. Temperatures are raised even higher, and sometimes chemicals are added, to help bubbles rise and escape. The glass becomes still and clear. Next comes stirring. Large paddles slowly churn the molten glass. This ensures every part has exactly the same silicate composition – critical for optical uniformity. Once perfectly homogeneous, the molten glass is carefully cooled down (annealed) in a controlled manner. This controlled cooling relieves internal stresses that could cause the glass to crack or distort light. The result is a large block of pristine optical glass. This block is then cut, ground, and polished with extreme precision into lenses, prisms, or windows. Every step relies on understanding and controlling the silicate chemistry.

4. Real-World Applications: Silicates Powering Our Vision

Silicates in optical glass are everywhere you need to see clearly, precisely, or far away. Look inside any camera lens, from a simple point-and-shoot to a professional DSLR. Multiple lens elements, each made from specific silicate glass types, work together to focus light sharply onto the sensor, correcting color errors and distortions. Binoculars and telescopes rely heavily on silicate glass. Large objective lenses gather faint light from distant stars, while prisms (often made from silicate glass like BK7) flip the image the right way up. Microscopes use specialized silicate glass lenses to magnify the tiny world, revealing details invisible to the naked eye. Projectors, both in movie theaters and conference rooms, need high-quality silicate lenses to throw bright, sharp images onto screens. Fiber optic cables, the backbone of the internet, use ultra-pure silicate glass fibers. Light pulses carrying data travel down these thin glass threads with minimal loss. Laser systems use silicate glass components like lenses, windows, and prisms to steer and focus powerful beams for cutting, welding, surgery, or scientific research. Even the lenses in your eyeglasses or the sensors in your smartphone camera likely involve silicate glass. Any device that manipulates light for imaging, communication, or measurement almost certainly uses silicate-based optical glass.

5. Silicate Optical Glass FAQs

Q1: Is all glass made from silicates?

Most common glass, like window glass or bottles (soda-lime glass), is silicate-based. Special glasses exist, like phosphate glasses for certain lasers or fluoride glasses for infrared optics. But the vast majority of optical glass, especially for visible light applications, relies on silicates.

Q2: Can silicate glass handle lasers?

Yes, but it depends. Standard silicate glasses work well for many low and medium-power lasers. For very high-power lasers, special compositions or ultra-pure grades are needed. These resist damage from the intense light better. Silicate glass is a key material for laser optics.

Q3: Why not just use plastic lenses?

Plastic lenses are cheaper and lighter, great for simple glasses or disposable cameras. But silicate glass wins for high performance. It’s much harder, scratch-resistant, and has far superior optical properties. Glass offers better clarity, less color distortion, and handles heat and environmental exposure better. Precision optics demand glass.

Q4: How do silicates affect the color of the glass?

Pure silicate glass is very clear. But impurities can cause color. Iron impurities, even tiny amounts, can give a greenish tint. Glassmakers use very pure materials and sometimes add “decolorizers” like manganese dioxide or selenium to counteract this, ensuring the glass stays colorless for optical use.

Q5: Is the glass in my smartphone camera special?

(Application Research Of Silicates In Optical Glass)

Yes. Smartphone camera lenses are incredibly small and complex. They use specialized silicate glass types. These glasses are designed to be ultra-thin, highly durable, and have excellent optical properties despite their miniature size. They often involve advanced manufacturing techniques to meet the demands of compact, high-resolution mobile imaging.