Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Title: Difficult Carbon: The Secret Sauce Powering Tomorrow’s Sodium Batteries? .

(Application Research Of Hard Carbon In Sodium Ion Batteries)

Blog Post: .

Batteries are everywhere. Phones, vehicles, also grids keeping sunlight and wind. Lithium commonly gets the limelight. But suppose there’s a less expensive, a lot more numerous different gurgling up? Enter sodium-ion batteries. And their celebrity gamer? Tough carbon. This isn’t simply another laboratory experiment; it’s a material trembling points up. Let’s fracture open the story of difficult carbon and see why it’s triggering such a buzz in the salt battery globe.

1. Exactly What is Difficult Carbon? .

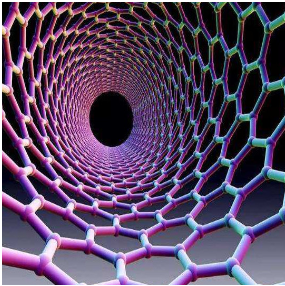

Think of carbon. Pencil lead? That’s graphite, soft and unsafe. Diamonds? Super hard, extremely structured. Difficult carbon sits someplace in the middle, yet it’s absolutely not graphite. Picture little, unpleasant heaps of graphene sheets. These sheets are all jumbled up, like a heap of old and wrinkly paper threw randomly. This creates a framework filled with nooks, crannies, and spins. Researchers make it by warming up things abundant in carbon– think sugar, wood, also old coconut shells– to truly high temperatures without oxygen. The key point? Its framework is disordered. It has lots of issues and areas. This messy, permeable nature is in fact its superpower for salt batteries. It’s tough, manages high warmth well, and conducts electrical energy halfway decent. Unlike graphite’s neat layers developed for tiny lithium ions, hard carbon’s disorderly innards are perfect for the bigger salt ions.

2. Why Hard Carbon for Sodium-Ion Batteries? .

Sodium ions are bigger than lithium ions. A lot larger. Trying to shove a large salt ion right into graphite’s neat, limited layers resembles trying to compel a basketball right into a tennis sphere tube. It does not fit well. The graphite structure gets damaged. Efficiency plummets. Tough carbon is different. Its disordered structure has uneven gaps and tunnels. These spaces are perfect for the bigger salt ions to insinuate and out quickly. Think of it like a custom-made garage for a huge vehicle versus trying to park it in a portable vehicle place. Tough carbon gives that sizable “garage.” It likewise supplies lots of spots on its surface and inside its pores where sodium ions can briefly park during billing and discharging. This combination indicates difficult carbon can keep a great deal of sodium. It charges reasonably fast. It lasts for lots of cycles without breaking down. Most importantly, it deals with products already readily available and inexpensive. This makes sodium-ion batteries utilizing hard carbon possibly much cheaper than lithium-ion.

3. How Do We Make and Use Difficult Carbon Anodes? .

Making difficult carbon anodes starts with selecting the right raw stuff. Biomass resources are prominent– things like peanut coverings, corn cobs, timber chips, even old tires. Oil pitch functions also. The picked material gets cooked in a heating system. This happens with no air (pyrolysis). The temperature is important– typically in between 1000 and 1500 degrees Celsius. This extreme warm repel whatever except the carbon, leaving behind that messy, hard framework. In some cases, additional actions assist. Cleaning the product first. Mixing it with chemicals like potassium hydroxide prior to heating. This can develop much more pores and enhance efficiency. After cooking, the difficult carbon is a black powder. This powder obtains combined with a sticky binder and a conductive additive like carbon black. The mixture is spread onto thin steel foil, usually copper. This covered aluminum foil is dried out and pushed. After that it’s reduced into the appropriate size and shape. This becomes the anode– the adverse electrode– inside a sodium-ion battery cell. The difficult carbon anode rests opposite a cathode made from products like layered oxides or Prussian blue analogs. Sodium ions shuttle in between them via a fluid electrolyte when the battery costs and discharges.

4. Real-World Applications Powered by Difficult Carbon & Sodium .

Sodium-ion batteries with tough carbon anodes aren’t science fiction anymore. They’re relocating into the real life. Their largest toughness? Expense. Salt is dirt cheap contrasted to lithium. Hard carbon from biomass can be affordable too. This makes them ideal for massive energy storage where expense per kilowatt-hour is king. Assume huge battery farms saving solar energy for the night or wind power for calm days. They’re additionally excellent for powering things like electric scooters, bikes, and smaller city cars where full throttle and severe variety aren’t the primary objectives, yet affordability is vital. They are discovering usage in backup power systems for cell towers and information centers. Their far better performance in very winter contrasted to some lithium batteries is an additional plus. Chinese business like CATL and HiNa Battery are already producing them. They see these batteries dominating the market for stationary storage space and light electrical transportation. The lower cost and use of plentiful materials (sodium, iron, manganese, carbon from waste) make them a sustainable choice for scaling up renewable energy usage worldwide.

5. Tough Carbon in Salt Batteries: Your Frequently Asked Questions Answered .

Is this innovation ready currently? Yes, however still boosting. Business are manufacturing them today, generally in China. They work well for specific uses like power storage space and light transport. Performance is getting better annually.

Are salt batteries with tough carbon safe? Typically, yes. They are typically taken into consideration much safer than some lithium-ion types. Difficult carbon is secure. Salt is less responsive than lithium. They commonly utilize more secure electrolytes. They produce less warmth during problems. They are less susceptible to thermal runaway fires.

How much time do they last? Cycle life is improving rapidly. Good cells now take care of a number of thousand cycles. This is suitable for several applications, particularly stationary storage space where long life is important. It’s obtaining closer to lithium-ion life expectancy.

Are they actually much more sustainable? Possibly, yes. Sodium is vastly extra bountiful than lithium. Tough carbon can be made from waste biomass (like nutshells, sawdust). This stays clear of mining issues linked to lithium and cobalt. Recycling processes are also being established. Their reduced cost aids release more renewable resource storage space.

(Application Research Of Hard Carbon In Sodium Ion Batteries)

What are the primary challenges left? Energy density is the huge one. They save less power per pound than the best lithium-ion batteries. This limits their usage in things like long-range electric automobiles or phones. Making tough carbon efficiency really consistent from batch to batch is likewise an emphasis for makers. Matching the ultra-fast charging of some lithium batteries is an additional area for improvement.