Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Silicates: The Secret Heroes in Your Gizmos .

(Application Progress Of Silicates In Electronic Packaging Materials)

Ever question how your phone keeps cool throughout a marathon video gaming session? Or what keeps your laptop computer’s mind safe from bumps and heat? The answer could amaze you. It involves materials dug straight from the earth, transformed right into state-of-the-art guards. We’re discussing silicates stepping into the spotlight of electronic packaging. Forget boring rocks; these minerals are the unsung heroes making contemporary electronic devices possible. Allow’s split open the instance and see just how silicates are altering the video game.

1. Just What Are Silicates? .

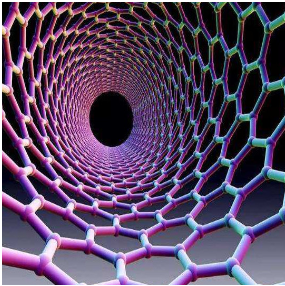

Silicates are everywhere. They are the most common group of minerals on Earth. Think quartz, feldspar, clay, also mica. Chemically, they all share a fundamental building block: silicon and oxygen atoms connected together in frameworks called tetrahedra. This silicon-oxygen bond is unbelievably strong and steady. These tetrahedra can connect in numerous ways, forming different silicate frameworks. Some are straightforward chains, others complex 3D frameworks. This variety offers silicates a substantial range of properties. We find them in sand, glass, porcelains, and even gemstones. In electronic devices, we do not utilize raw beach sand. We utilize extremely improved silicate powders, typically incorporated with other aspects like aluminum, magnesium, or boron. These crafted silicate ceramics become the foundation of essential product packaging elements. Their natural abundance and security make them an amazing starting factor for state-of-the-art materials.

2. Why Are Silicates Perfect for Electronic Packaging? .

Electronic packaging has a laborious. It shields delicate chips from the outside world. It additionally manages warm and electrical power. Silicates, specifically crafted porcelains, radiate here. First, they are electric insulators. This is crucial. Product packaging has to quit electrical signals from leaking or short-circuiting. Silicate ceramics obstruct electrical power really properly. Second, they handle warmth superbly. Modern chips create a lot of warm. Silicate materials perform this heat away successfully. This quits chips from overheating and failing. Third, they are extremely secure. They do not broaden or shrink much with temperature level adjustments. This thermal security avoids fractures and breaks. Product packaging needs to make it through soldering procedures and day-to-day usage. 4th, silicates are strong and rigid. They secure chips from physical damages. Lastly, they withstand chemicals and wetness. Moisture or harsh materials will not quickly harm them. Silicates offer an unusual combination: excellent insulation, good warm monitoring, high stability, strength, and chemical resistance. This mix is difficult to beat for shielding important electronic devices.

3. Just How Are Silicates Made Use Of in Packaging? .

Silicates don’t go into packaging as raw minerals. They undertake advanced processing. One of the most usual form is ceramic. Right here’s a simplified check out the procedure. Designers start with ultra-pure silicate powders. These powders might be alumina (aluminum oxide), silica itself, or complicated mixes like aluminum nitride or forsterite. They mix these powders with binders and other additives. The mix obtains shaped. Common shaping approaches consist of pushing it right into mold and mildews, casting it like slurry, or even 3D printing. The shaped component, called a “environment-friendly body,” is still fragile. Following comes shooting. The eco-friendly body goes into a high-temperature kiln. This is sintering. The intense warmth integrates the powder bits together. The binder burns away. The result is a thick, hard ceramic part. This component comes to be the substrate, the base layer holding the chip. It might end up being the real estate or lid securing the chip. In some cases, silicates are made use of in glass type. Unique glasses seal elements together. Silicate-based composites are additionally typical. Blending silicate porcelains with various other products like polymers creates unique residential or commercial properties. Engineers frequently modify the powder dishes, ingredients, and processing actions. The objective is constantly the very same: develop the excellent protective shell for sensitive electronic devices.

4. Secret Applications: Silicates at work .

Silicates play crucial roles across lots of digital tools. Look inside nearly any kind of device, and you’ll likely discover them. One significant usage is chip substratums. The tiny circuit board holding the silicon chip is usually ceramic. Alumina (Al2O3) is the workhorse right here. It gives a stable, shielding base. For high-power tools requiring much better heat retreat, aluminum nitride (AlN) substrates are common. These handle warm far better than alumina. Silicate ceramics likewise create the protective bundles around chips. These packages secure the chip from dirt, wetness, and physical shock. They frequently have metal leads for link. One more crucial application is sealing. Glass including silicates seals steel covers onto ceramic plans. This produces a hermetic seal, keeping air and wetness out completely. Silicate-based products are additionally key in published circuit boards (PCBs). The fiberglass reinforcing most PCBs? That’s woven from silica glass fibers. Even the solder mask safeguarding the copper traces often includes silicate fillers. Thermal management pastes and pads, used to draw heat away from chips, regularly include silicate powders. From your smartphone and laptop to your car’s engine control device and industrial power modules, silicates supply crucial protection and efficiency.

5. Silicates in Packaging: Usual Concerns .

Q: Aren’t silicates simply sand? How is that high-tech? .

A: Yes, the raw product originates from minerals like sand. However it’s not coastline sand. The silicates used are very cleansed. They are processed under rigorous problems. The resulting porcelains are crafted products with accurate properties. Consider it like transforming crude oil into sophisticated plastic.

Q: Are silicate-based bundles fragile like glass? .

A: Not truly. While silicate porcelains are difficult and brittle compared to metal, they are extremely strong under compression. Packaging style considers this. Designers shape them to avoid sharp impacts on slim sides. The outcome is packaging tough sufficient for daily electronic devices.

Q: Can silicates take care of the warm from effective cpus? .

A: Absolutely. This is a major strength. Typical alumina works well for numerous chips. For extreme warmth, like in high-power LEDs or server processors, materials like aluminum nitride (AlN) or beryllium oxide (BeO – though much less typical currently) are utilized. These silicate-based porcelains perform warm much better than many metals.

Q: Exist any type of drawbacks to utilizing silicates? .

A: Expense and processing can be variables. Making high-purity ceramics needs considerable energy. Accuracy machining of difficult ceramics includes cost. They are additionally more challenging to reuse than some metals. Research concentrates on making processing less costly and locating even more lasting choices.

Q: Will silicates be changed by newer products? .

(Application Progress Of Silicates In Electronic Packaging Materials)

A: It’s unlikely quickly. Their combination of electric insulation, thermal performance, stability, and expense is tough to match. New composites typically still make use of silicates as a base. They stay essential. Future product packaging may utilize innovative silicate types or composites, yet the core material remains appropriate.