Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Title: Silicide Sensors: The Secret Sauce for Supercharged Sensing

(Application Of Silicide In Sensor Sensitive Materials)

Imagine your auto promptly discovering engine difficulty before it strands you. Or a clinical probe noticing the faintest chemical change inside your body. What makes such super-sensing feasible? Commonly, it’s a small yet magnificent product: silicide. This isn’t sci-fi. Silicides are silently reinventing exactly how sensing units see, really feel, and react to the globe. Allow’s study this concealed hero of modern-day picking up technology.

What Exactly is Silicide? .

Think about silicide as an unique alloy. It creates when silicon bonds with certain steels. Common companions include platinum, palladium, nickel, cobalt, and titanium. This bonding develops something entirely new. Silicides aren’t just blends. They are distinct substances with unique homes silicon and the metal alone don’t possess. These properties make them super stars in the sensing unit world. They act as the crucial interface, the energetic component that in fact communicates with things being gauged– be it warm, gas, light, or stress. Without this delicate layer, many advanced sensors simply would not function as well or in any way.

Why Silicides Rule in Sensor Sensitivity .

So why pick silicide over various other products? Its benefits are clear and powerful. Initially, silicides are incredibly stable. They handle high temperatures without damaging down. This is important for sensing units inside hot engines or commercial processes. Second, they are tough. They withstand rust from rough chemicals, guaranteeing the sensor lasts longer and remains precise. Third, they play exceptionally well with silicon chips. Because most sensors are built on silicon platforms, silicides incorporate effortlessly. This combination is crucial for miniaturization and performance. 4th, they have amazing electric homes. They perform electricity well and can develop sharp electrical junctions. These joints are vital for equating a physical modification (like temperature level rising) into a clear electric signal the sensor can read. Silicide gives a trusted, high-performance path for signals. In other words, silicide offers the excellent mix of stability, longevity, compatibility, and electrical prowess required for excellent noticing.

Just How Silicides Power Up Sensing Unit Efficiency .

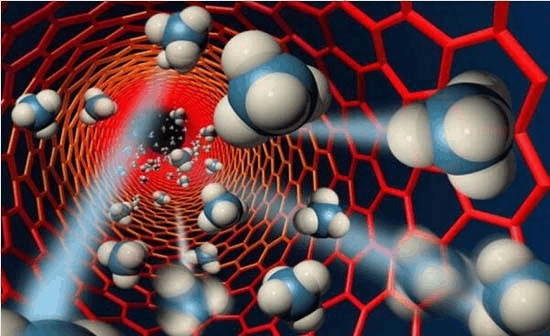

The magic occurs at the atomic level. Silicides work as the sensor’s frontline. Take a temperature sensor. A platinum silicide layer may be used. As warm boosts, the electric resistance of the silicide adjustments in an accurate, foreseeable method. The sensing unit gauges this resistance modification and determines the temperature. In gas sensing units, details silicides react selectively with target gases like hydrogen or carbon monoxide. When gas molecules interact with the silicide surface area, they alter its electric homes. This change produces an obvious signal. For light sensing units (photodetectors), silicides like platinum silicide or iridium silicide are superb at soaking up particular wavelengths of light. When light hits them, they create electric costs symmetrical to the light strength. Stress sensing units may utilize silicides in stress determines. The silicide layer flaws a little under stress, changing its resistance. Silicides supply the crucial web link between the real world and the electronic signal.

Where Silicide Sensors Make a Genuine Distinction .

You may not see them, but silicide sensors are all over, making things smarter and safer. In your automobile, silicide-based temperature level sensing units monitor engine heat and exhaust gases. They help maximize gas efficiency and lower exhausts. Gas sensors with palladium silicide sniff out hazardous leaks in homes or industrial plants. Clinical devices rely upon them. Think about little probes gauging blood oxygen or identifying particular biomarkers with extraordinary precision. Industrial setups utilize them greatly. They monitor furnace temperature levels, spot toxic fumes, and make sure procedure control in extreme settings. Aerospace is another big individual. Silicide sensing units endure severe conditions in jet engines and spacecraft. They keep an eye on important criteria. Also everyday tools advantage. Premium smoke alarm and ecological screens usually use silicide technology for better precision. Their ability to carry out reliably in difficult problems makes them vital across numerous areas.

Silicide Sensing Unit FAQs .

Are silicide sensing units expensive? They can be a lot more pricey than fundamental sensors, especially those utilizing rare-earth elements like platinum. However the price is usually warranted by their exceptional efficiency, longer life expectancy, and reliability in essential applications. Think about it as a financial investment in precision and longevity.

Can silicides pick up anything? Not whatever directly. Their sensing power depends heavily on which steel is bound with silicon. Platinum silicide excels in warmth discovery. Palladium silicide is fantastic for hydrogen gas. Nickel silicide is usually made use of in pressure sensors. The selection of steel customizes the silicide for certain jobs.

Are they secure? Yes, when effectively produced and encapsulated within the sensor device. The silicide layer itself is generally a very slim film securely bonded within the sensor structure. It positions no direct safety and security risk to individuals.

Why not utilize pure metal rather? Pure steels usually lack the thermal stability or chemical resistance needed. They can deteriorate quicker at high temperatures or corrode. Silicides combine the steel’s advantageous homes with silicon’s security and compatibility with electronics. They create a more robust picking up user interface.

(Application Of Silicide In Sensor Sensitive Materials)

What’s following for silicide sensors? Research study is expanding. Researchers are exploring brand-new metal mixes for better sensitivity to different targets. They are also dealing with nanostructured silicides to make sensing units also smaller sized, faster, and more energy-efficient. The objective is sensors that detect things we can’t gauge well today.