Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Catchy Title: Silicide Supercharge: The Secret Weapon in Your Battery’s Negative Electrode?

(Application Of Silicide In Negative Electrode Materials Of Lithium-Ion Batteries)

Blog Post:

Imagine your phone lasting days, not hours. Picture electric cars driving hundreds more miles on a single charge. This future might rely on a tiny material hero: silicide. Buried deep within the negative electrode of advanced lithium-ion batteries, silicide is stepping into the spotlight. Forget basic silicon; silicide offers a smarter path to the energy storage revolution we desperately need. Let’s uncover why scientists are so excited about this under-the-radar material.

What Exactly is Silicide?

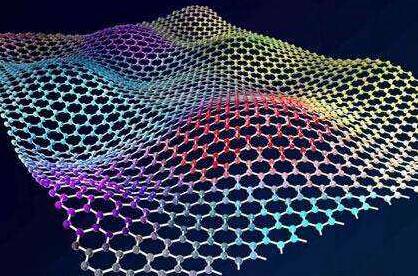

Think about silicide as silicon’s tougher cousin. Silicon alone is great at storing lithium ions – that’s the energy. But silicon has a big problem. It swells up huge when charged, like a sponge soaking up water. Then it shrinks back down when you use the power. This constant swelling and shrinking breaks the silicon apart over time. Your battery dies fast. Silicide changes the game. It’s not pure silicon. It’s silicon chemically bonded with another metal. Common partners include magnesium, calcium, titanium, or iron. This bonding creates a new material. This new material inherits silicon’s amazing ability to hold lots of lithium ions. Crucially, it also gains much better stability. The swelling problem is drastically reduced. Silicide acts like a reinforced structure, holding its shape far better during the battery’s charging and discharging cycles. It’s a fundamental shift in the negative electrode material.

Why Use Silicide Instead of Graphite?

Graphite is the standard stuff in almost all lithium-ion batteries today. It works okay, but it’s hitting its limits. We need more power packed into smaller, lighter batteries. Graphite can only hold so much lithium. Silicon, and silicide by extension, can hold nearly ten times more lithium than graphite! That means potentially ten times more energy in the same space. But silicon’s swelling problem made it unusable alone. Silicide offers a brilliant solution. It delivers most of silicon’s incredible capacity. It does this while being much more stable. Graphite is also pretty slow at letting lithium ions move in and out. This limits how fast you can charge or discharge the battery. Silicide often conducts electricity better than graphite. This means potentially faster charging times for your devices and more power available instantly for your electric car. Silicide tackles both the capacity and the speed bottlenecks graphite faces.

How Do We Put Silicide into Battery Electrodes?

Getting silicide into a working battery electrode isn’t simple. Scientists and engineers use clever methods. One main way involves mixing silicon powder with the chosen metal powder. Think magnesium or titanium. They heat this mixture very carefully under controlled conditions. The heat makes the silicon and metal react, forming the silicide compound. Another method coats silicon particles directly with the metal. Then, heat treatment causes the metal to react with the silicon surface, creating a protective silicide layer. This layer acts like armor. Once the silicide powder is made, it needs to be turned into a functional electrode. This means mixing the silicide particles with special glue (a binder) and a conductor (like carbon black). This slurry is spread thinly onto a metal foil, usually copper. It’s then dried very carefully. The key is making sure the silicide particles are the right size and shape. They need to be small enough to handle the lithium movements without cracking. The binder must hold everything together tightly through all the swelling and shrinking that still happens, just less severely. It’s a precise balancing act.

Where Will Silicide Batteries Make a Difference?

The potential uses for silicide-enhanced batteries are huge. The most obvious impact is in electric vehicles (EVs). Everyone wants EVs that go further on a charge and charge much faster. Silicide’s high capacity and potentially better conductivity directly address these needs. Lighter batteries with more range are crucial for wider EV adoption. Next, think about your gadgets. Phones, laptops, tablets, smartwatches – we hate it when they die quickly. Silicide batteries could mean phones lasting two or three days easily. Laptops could run all day without needing the charger. Wearables could become smaller yet last weeks. Power tools are another big market. Imagine a cordless drill that works longer and charges in minutes, not hours. Silicide can make that possible. Even large-scale energy storage for solar and wind farms could benefit. While cost is always a factor for grid storage, the improved performance and lifespan of silicide batteries could make them viable for storing renewable energy more effectively. Anywhere we currently use lithium-ion batteries, silicide promises a significant upgrade.

Silicide in Batteries: Your Questions Answered

Is silicide safe? Safety is always the top priority in battery research. Early studies show silicides can form more stable interfaces with the battery’s electrolyte compared to pure silicon. This potentially reduces risks like thermal runaway. Research is ongoing to ensure they meet all safety standards before commercial use. Safety testing is rigorous.

Will silicide batteries last longer? That’s the goal! By reducing the damaging swelling of silicon, silicide electrodes should withstand many more charge-discharge cycles. This means your battery won’t lose its capacity as fast. Your device stays useful longer. Durability is a key target.

How soon can I buy one? Silicide battery tech is moving beyond the lab. Several companies are actively developing prototypes. We might see them in high-end, specialized devices within a few years. Mass-market adoption in phones and cars will likely take longer. Production scaling and cost reduction are challenges. It’s coming, but not tomorrow.

Are they expensive? Initially, yes. The materials and manufacturing processes are more complex than graphite batteries. Costs should come down as production scales up. The performance benefits – longer range, faster charging – might justify a higher price for many users, especially in premium EVs and electronics. Cost is a hurdle being worked on.

(Application Of Silicide In Negative Electrode Materials Of Lithium-Ion Batteries)

Can silicide work with other new battery tech? Absolutely! Silicide is primarily about improving the negative electrode. It could potentially be paired with advanced positive electrodes (like lithium-rich cathodes or sulfur) and better electrolytes (like solid-state). This combo could unlock even bigger leaps in battery performance. Silicide is one piece of a larger puzzle.