Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Title: Silicates: The Trump Card for Safer, Smarter Battery Separators?

(Application Exploration Of Silicates In Battery Separator Materials)

Blog site: .

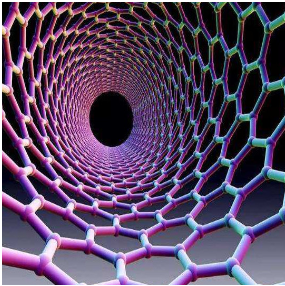

Batteries power our globe. Phones, laptop computers, electrical cars and trucks– they all rely on saving power safely and efficiently. Inside every lithium-ion battery, an essential yet usually neglected component works quietly: the separator. This slim membrane layer keeps the favorable and negative electrodes apart. It protects against short circuits. It permits ions to stream easily during billing and releasing. The separator is crucial for battery performance and safety and security. Now, scientists and designers are transforming to a shocking product to make separators even much better: silicates. This isn’t science fiction. It’s occurring in labs and manufacturing facilities today. Allow’s check out how silicates are ending up being the secret component for next-generation battery separators.

Main Item Keywords: Silicates, Battery Separators.

1. What Exactly Are Silicates Carrying Out In Battery Separators? .

Silicates are common minerals. Think about sand, clay, or quartz. They are made from silicon and oxygen, frequently incorporated with other elements like light weight aluminum or magnesium. In battery separators, we’re not talking about huge portions of rock. We’re talking about tiny bits or layers. These are added to the separator product itself. The separator is normally a porous plastic film, like polyethylene or polypropylene. Silicates are incorporated into this movie. They can be blended right into the plastic. They can form a slim layer externally. Sometimes, they are embedded within the separator’s structure. The goal is to improve the separator’s residential or commercial properties utilizing the distinct capabilities of silicates. It has to do with providing the separator superpowers stemmed from the planet itself.

2. Why Inconvenience Putting Silicates right into Separators? .

Common plastic separators function. However they have restrictions. Security is a major worry. If a battery obtains too hot, the plastic separator can reduce or thaw. This causes the electrodes to touch. The outcome? Fire or surge. Performance is an additional concern. Separators need to let lithium ions relocate quickly. Slow ion movement indicates slow billing and reduced power result. Stability matters as well. Batteries weaken over time. Separators need to endure severe chemical settings inside the battery for years. Silicates supply options. They are exceptionally heat-resistant. They don’t melt like plastic. They can literally strengthen the separator. Silicates can likewise communicate with the electrolyte liquid inside the battery. They can aid ions relocate quicker. They might even help develop a much more secure safety layer on the electrodes. Making use of silicates takes on the core weak points of traditional separators head-on. It makes batteries more secure, much faster, and longer-lasting.

3. How Are Silicates Really Contributed To Separator Products? .

Obtaining silicates right into separators requires creative design. It’s not almost mixing sand into plastic. The silicates require to be refined. They are ground down into very fine powders. These particles are nanometers or micrometers in size. This ensures they do not obstruct the separator’s pores. Pores are essential for ion flow. There are different approaches for integration. One typical means is covering. A slurry containing silicate particles is used straight onto the surface of the existing plastic separator film. This develops a protective silicate layer. Another approach is blending. Silicate particles are mixed straight into the molten plastic before it’s stretched into the slim separator movie. This installs the silicates throughout the product. A third method includes producing composite membrane layers. Right here, the silicate material might develop a scaffold or network combined with polymers. The chosen method relies on the kind of silicate utilized. It likewise depends on the specific property designers want to enhance the majority of. The trick is making certain the silicates are equally distributed. They have to not block the pores. They must bond well with the plastic.

4. What Real-World Applications Gain From Silicate-Enhanced Separators? .

The influence of silicate separators is being felt throughout the battery market. Electric cars are a prime beneficiary. EV batteries need severe safety and security. They additionally require quick billing and lengthy driving varieties. Silicate separators substantially decrease fire threat by preventing thermal runaway. Their boosted thermal stability is important right here. They likewise enable faster ion transportation. This suggests quicker charging times at stations. Consumer electronics additionally get. Laptop computers and phones using silicate separators are much less likely to overheat. Battery life might improve. Power tools need ruptureds of high power. Silicate separators assist provide that power accurately. Power storage space is one more big area. Large batteries keeping solar or wind power need to be secure and secure for years. Silicate-enhanced separators offer that long-term reliability. They handle the continuous billing and discharging cycles much better. Even arising modern technologies like solid-state batteries are checking out silicate layers. These layers function as protective barriers. They aid take care of ion flow effectively. The applications are wide because the core advantages– security, rate, stability– are universally needed.

5. Frequently asked questions: Your Silicate Separator Questions Answered .

Q: Aren’t silicates hefty? Will not this make batteries bulkier? .

A: The quantities made use of are very little. We’re discussing thin finishings or small particles mixed in. The weight rise is minimal. The efficiency and security gains far outweigh any type of minor weight enhancement.

Q: Are silicate separators a lot more expensive? .

A: First costs could be a little higher than standard plastic separators. However silicates themselves are abundant and economical products. Assume sand! The processing includes some cost. However, the lasting benefits are considerable. Safer batteries suggest less recalls. Longer-lasting batteries mean much less frequent replacement. Faster charging enhances user experience. These elements make silicate separators cost-efficient overall.

Q: Do silicate separators collaborate with all battery kinds? .

A: A lot of research concentrates on lithium-ion batteries. This includes typical types like Lithium Iron Phosphate and Nickel Manganese Cobalt. The concepts can apply to various other lithium-based chemistries. Sodium-ion batteries are additionally checking out similar principles. Compatibility relies on the specific silicate and the battery chemistry. However lithium-ion continues to be the main target and recipient today.

Q: Can silicates trigger any troubles inside the battery? .

A: Study is continuous. The major problem is making sure silicates do not respond adversely with the electrolyte or electrodes gradually. Mindful option of the silicate kind is vital. Bit size and circulation are also crucial. If done right, silicates really boost stability and lower unwanted side reactions. They aid develop much better safety layers. Quality control during production is vital to stay clear of any type of potential concerns.

Q: Are batteries with silicate separators readily available to buy currently? .

(Application Exploration Of Silicates In Battery Separator Materials)

A: Yes, certainly. Several major battery makers and separator distributors have actually established business items. These are utilized in EVs, power devices, and consumer electronics. Adoption is proliferating. As the innovation develops and sets you back maximize, anticipate to see silicate separators become the requirement, not the exception. The change is happening now.