Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Magnetic Wonders: The Unforeseen Function of Silicates .

(Application Attempts Of Silicates In Magnetic Materials)

Forget every little thing you believed you found out about dull old sand. Deep within the globe of cutting-edge materials scientific research, silicates– yes, those usual compounds found in rocks, clay, and glass– are staging a peaceful revolution. They’re tipping onto the phase of magnetic materials, appealing remedies to some challenging troubles. Allow’s study this fascinating blend of the old and the ultra-modern.

Main Product Keywords: Silicates, Magnetic Products.

1. What Are Silicates and Magnetic Materials? .

Silicates are everywhere. They create the bulk of the Earth’s crust. Assume sand, quartz, clay, mica, and also asbestos. Their fundamental building block is the silicon-oxygen tetrahedron. 4 oxygen atoms border one silicon atom. These tetrahedra web link with each other in plenty of methods. This creates a massive family of minerals and artificial substances. They are known for security, insulation, and chemical resistance. Usually, they are cheap and bountiful.

Magnetic materials are various. They create electromagnetic fields. They react to magnetic fields. Usual examples consist of iron, nickel, cobalt, and their alloys. Ferrites (ceramic magnets made from iron oxide and other steels) are additionally principals. We find magnets in motors, generators, hard disks, audio speakers, clinical tools, and sensors. Their efficiency depends on homes like magnetic toughness (saturation magnetization), resistance to demagnetization (coercivity), and just how well they carry out magnetic change (permeability).

So, silicates are steady insulators. Magnetic materials are typically conductive steels or porcelains producing electromagnetic fields. Incorporating them seems odd in the beginning glance. Why blend an insulator with a magnetic conductor? The answer depends on developing composites with distinct, hybrid buildings.

2. Why Combine Silicates with Magnetic Materials? .

Designers and researchers face constant difficulties with typical magnetic materials. Pure steels like iron can rust. They can experience power losses, specifically at high regularities. This is due to eddy currents– swirling currents induced within the conductor. Ferrites are much better insulators, minimizing eddy currents. But they can be brittle. Their magnetic stamina is often lower than metal alloys. Locating materials that are strong, reliable, steady, and cost-efficient is tough.

This is where silicates come in. Scientist discover them for a number of compelling reasons:.

Electrical Insulation: Silicates are superb electric insulators. Installing magnetic bits within a silicate matrix can considerably reduce swirl current losses. This is essential for applications involving alternating currents or high regularities, like transformers or high-speed motors.

Thermal Security: Several silicates endure very heats. They don’t quickly decompose or melt. This shields the magnetic fragments within a composite. It allows procedure in hotter settings.

Chemical Resistance: Silicates stand up to deterioration from water, acids, and bases much better than many pure metals. A silicate finish or matrix can shield magnetic fragments. This enhances the general longevity and lifespan of the material.

Mechanical Reinforcement: Silicates can include firmness and structural honesty. They make fragile magnetic ceramics harder. They provide a stiff structure for magnetic bits.

Expense and Wealth: Silica (SiO ₂), the base for lots of silicates, is unbelievably economical and abundant. Using it can dramatically reduce the price of sophisticated magnetic compounds.

Tailoring Residences: By thoroughly picking the silicate type and the magnetic filler, scientists can design compounds. These compounds have specific magnetic stamina, electrical resistivity, thermal actions, and mechanical homes. One product does not fit all needs.

The goal isn’t to change powerful neodymium magnets. It’s to create smarter compounds. These compounds address certain issues in demanding applications.

3. Just How Are Silicates Integrated into Magnetic Materials? .

It’s not merely mixing sand with iron filings. Producing efficient silicate-magnetic compounds requires innovative strategies. The aim is to accomplish a solid bond. This bond makes certain the silicate matrix appropriately surrounds and safeguards the magnetic fragments. Below are vital approaches:.

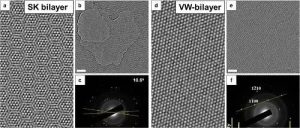

Sol-Gel Process: This is preferred. It begins with liquid forerunners (like silicon alkoxides). These forerunners go through chemical reactions. They create a gel. Magnetic nanoparticles (like iron oxide) are spread within this gel. The gel is after that dried and warmed (calcined). This produces a solid, frequently glazed, silicate matrix. The magnetic fragments are ingrained within it. This permits outstanding blending at the nanoscale.

Sintering: Fine powders of a magnetic product (like a ferrite) and a silicate (like powdered glass) are mixed. The mix is pressed right into a desired shape. It’s after that warmed to a heat below the melting point. The fragments fuse with each other. This forms a dense ceramic compound. Controlling the temperature level and time is important. It prevents unwanted responses and makes certain excellent bonding.

Layers: Magnetic fragments (microns or nanometers in size) can be covered with a thin layer of silicate. Techniques include chemical rainfall or specialized deposition strategies. This creates a core-shell structure. The magnetic core is secured by the silicate covering. These layered particles can then be made use of as is. They can additionally be compressed right into larger elements.

Glass-Ceramic Routes: Certain silicate glasses include parts that can develop magnetic crystals. The glass is melted and shaped. It is then given a specific heat therapy. This therapy creates small magnetic crystals (like magnetite) to expand within the lustrous silicate matrix. This creates a solid, incorporated composite product.

Polymer-Assisted Techniques: Silicate forerunners and magnetic particles are sometimes blended into a polymer binder. This paste can be formed a lot more conveniently. Later home heating burns off the polymer. It sinters the silicate and magnetic particles together.

The selected approach depends on the preferred residential properties. It additionally relies on the scale of manufacturing and cost targets. Nanoscale blending frequently provides the best performance. Yet it can be more complicated and costly.

4. Where Are Silicate-Magnetic Composites Made Use Of? .

These hybrid products are locating particular niches. They stand out where conventional magnets face limitations:.

High-Frequency Power Electronics: This is a significant location. Believe transformers and inductors in switch-mode power supplies. Swirl existing losses are a big issue at high frequencies. Silicate composites (like ferrites embedded in glass) provide high electric resistivity. They considerably reduced these losses. This improves performance. It enables smaller, cooler-running elements.

Electromagnetic Protecting: Instruments need defense from roaming electromagnetic fields. Silicate compounds can be developed to take in or mirror these areas. Their tunable electric and magnetic buildings make them beneficial. They protect sensitive electronic devices.

Biomedical Applications: Magnetic nanoparticles coated with biocompatible silicates (like silica) are encouraging. They are used in magnetic hyperthermia cancer cells therapy. The bits are injected. They are heated by an alternating magnetic field. This kills cancer cells. Silicate coatings make them secure in the body. They enable surface area alteration for targeting. They are likewise discovered for magnetic resonance imaging (MRI) comparison representatives and targeted drug distribution.

Sensors: The magnetic homes of these compounds can transform. They respond to stress, temperature, or chemical environment. This makes them candidates for numerous sensing units. Silicates supply stability and protection.

Advanced Motors and Actuators: Decreasing eddy present losses is crucial in high-speed electric motors. Silicate-magnetic compounds make it possible for a lot more effective layouts. They allow procedure at greater speeds and power densities. This is specifically pertinent for electrical lorries and aerospace.

Durable Magnets in Rough Settings: Where rust or high temperatures deteriorate steel magnets, silicate composites provide strength. Examples consist of downhole drilling devices and sensors in chemical processing plants. The silicate matrix shields the magnetic bits.

Catalysis: Magnetic fragments covered with silicate can serve as catalyst supports. The magnetism allows easy separation of the driver from the response mixture using a magnet. This simplifies recycling.

5. FAQs Concerning Silicates in Magnetics .

Q: Can silicates themselves be magnetic? Normally not highly. Pure silica is diamagnetic (weakly repelled by magnets). Some unusual all-natural silicate minerals consist of iron or various other magnetic aspects. They show weak magnetism. But the actual power comes from incorporating silicates with strongly magnetic materials like iron, cobalt, nickel, or ferrites.

Q: Do these compounds make more powerful magnets than neodymium? Typically, no. Neodymium-iron-boron magnets are much stronger. Silicate composites are not around raw toughness. They concentrate on solving specific problems. These troubles include high-frequency losses, corrosion, and brittleness. They provide one-of-a-kind mixes of magnetic, electric, and mechanical buildings.

Q: Are silicate-magnetic composites costly? It varies. The raw products (silica, typical ferrites) are typically affordable. However innovative processing, particularly for nanostructured composites, can enhance cost. The trade-off is better performance and longer life in demanding applications. This often warrants the price.

Q: Exactly how temperature level resistant are they? This is an essential benefit. Numerous silicate glasses and porcelains endure very high temperatures. They conveniently surpass 1000 ° C. This secures the magnetic bits within. It enables procedure where polymer-based compounds or some metals would stop working. The actual limit depends on the details silicate and magnetic material utilized.

(Application Attempts Of Silicates In Magnetic Materials)

Q: Is this innovation new? The concept of compounds isn’t brand-new. Ferrites themselves are ceramic oxides. However actively designing and maximizing silicate-based matrices for magnetic composites got significant momentum. This happened with advancements in nanotechnology and processing methods over the last couple of decades. Research is extremely energetic now.