Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Anode Product Regrowth Technology in Power Battery Recycling

(Anode Material Regeneration Technology in Power Battery Recycling)

What Is Anode Material Regeneration Modern Technology

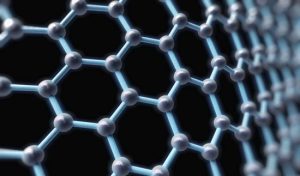

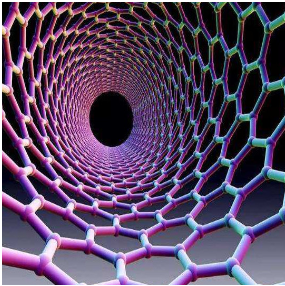

Anode product regeneration innovation is a wise means to bring made use of battery components back to life. When electrical automobiles or power storage systems get to completion of their life, their lithium-ion batteries still hold valuable materials. The anode– the component that stores lithium ions throughout billing– is usually made of graphite or silicon-carbon composites. As opposed to throwing these anodes away, regeneration modern technology cleans, repairs, and upgrades them so they can be reused in new batteries. This procedure saves resources and lower waste. It likewise helps reduce the demand for mining brand-new graphite, which is both costly and eco tiring. Companies like those behind man-made graphite anode manufacturing are now exploring just how to integrate recycled web content without compromising efficiency.

Why Is This Modern technology Important

The globe is using a lot more batteries than ever. Electric automobiles, phones, and grid storage all rely on lithium-ion power. Yet making new batteries requires a great deal of resources. Graphite alone represents around 10– 15% of a battery’s complete weight. Mining all-natural graphite or generating artificial versions makes use of huge quantities of power and develops contamination. If we keep discarding old anodes, we will run out of sustainable sources faster. Anode product regeneration tackles this issue head-on. It reduces the carbon footprint of battery production. It additionally makes battery reusing more rewarding by recuperating high-value components. And also, regenerated anodes can meet rigorous safety and security standards. For example, appropriate material design throughout regeneration can boost thermal stability, as shown in research studies on battery safety via material design. Simply put, this innovation sustains a cleaner, extra circular economy for power storage space.

Just how Does the Regeneration Refine Work

The procedure begins with accumulating spent batteries and securely discharging them. After that, the batteries are uncoupled to separate the cathode, anode, electrolyte, and case. The anode aluminum foil– generally copper coated with energetic product– is isolated. Next off, the active material is removed off the aluminum foil utilizing chemical or mechanical approaches. As soon as divided, the graphite or silicon-carbon mix goes through a number of cleansing steps to eliminate pollutants like lithium residues, binders, or electrolyte leftovers. After cleansing, the material is assessed for architectural damage. If needed, it is restructured or doped with additives to restore its capacity to save lithium ions successfully. Lastly, the regenerated powder is tested and combined right into new anode slurries. This approach is not simply theoretical– it’s already being scaled up by companies working with silicon-carbon anode material modern technology, where also tiny improvements in recycled content can increase total battery ability.

Applications of Regenerated Anode Materials

Regrowed anode materials are discovering real-world usage in many locations. One of the most evident remains in brand-new electrical car batteries. Automakers seeking to reduce expenses and meet sustainability objectives are eager to make use of recycled content. Power storage space systems for homes and solar ranches likewise benefit because they do not constantly require top-tier efficiency– simply dependability and reduced expense. Even customer electronics like laptop computers and power devices can include these products without users noticing any kind of difference. Some companies are additionally checking regenerated anodes in specialty applications, such as backup power for telecommunications towers or aquatic vessels. As battery standards progress, regenerated materials that satisfy efficiency standards will end up being more usual. The secret is uniformity: if every batch of recycled anode carries out like a fresh one, adoption will certainly grow quick. That’s why ongoing research right into quality control and product blending is so essential.

FAQs Concerning Anode Material Regrowth

Can regenerated anodes perform as well as brand-new ones? Yes, when correctly processed, they can match or perhaps go beyond the cycle life and capability of virgin products. Performance relies on just how extensively contaminations are eliminated and just how well the crystal framework is restored.

Is this modern technology widely made use of today? It’s still emerging but expanding rapidly. Pilot plants are running in Europe, China, and The United States And Canada, with full-blown business procedures anticipated within the next couple of years.

Does regeneration benefit all anode kinds? It functions ideal for graphite-based anodes, which dominate the market. Silicon-carbon blends are harder because of silicon’s propensity to swell, yet advancements in binder technology and particle engineering are making progress.

Is it more affordable than using new materials? Not always yet– yet as recycling framework improves and guidelines push for greener supply chains, prices are falling.

What happens to the copper foil after stripping? It’s normally cleansed and sold back to steel refiners, adding an additional revenue stream to the recycling procedure.

(Anode Material Regeneration Technology in Power Battery Recycling)

This technology isn’t practically taking care of old batteries– it has to do with constructing a smarter future for energy storage space. Every regenerated anode implies less mining, much less waste, and a lot more value from what we currently have.