Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Evaluating the Intercalation Dynamics of Lithium Ions in Graphite Layers

(Analyzing the Intercalation Dynamics of Lithium Ions in Graphite Layers)

What Is Lithium Ion Intercalation in Graphite Layers? .

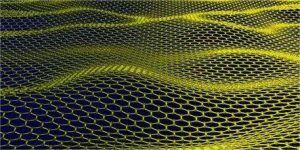

Lithium ion intercalation in graphite layers is an essential procedure that powers a lot of today’s rechargeable batteries. When you bill your phone or electric automobile, lithium ions relocate from the favorable electrode to the negative one. That adverse electrode is normally made of graphite. The ions slide between the piled carbon sheets of graphite without breaking its framework. This sliding-in activity is called intercalation. It is relatively easy to fix, which implies during discharge, the ions leave the graphite and go back to the other side. This back-and-forth motion is what allows batteries to store and release power over numerous cycles. Without this smooth insertion and removal of lithium ions, modern-day lithium-ion batteries just would not work.

Why Does Intercalation Issue for Battery Performance? .

Intercalation matters since it directly influences just how well a battery performs. If lithium ions can relocate easily into and out of the graphite layers, the battery costs quicker and lasts longer. However if the procedure is slow-moving or irregular, problems begin to appear. As an example, if too many ions crowd right into one spot, they might develop metal lithium instead of remaining as ions. This is called lithium plating, and it can trigger short circuits or even fires. Additionally, duplicated intercalation can emphasize the graphite framework over time, leading to splits or ability loss. That is why researchers invest a lot time examining how ions behave inside graphite. Understanding these characteristics helps engineers design more secure, a lot more efficient anodes. You can learn more about just how material selections impact safety and security in this discussion on battery safety through product style.

How Do Scientists Study and Enhance Intercalation Characteristics? .

Researchers utilize several devices to enjoy lithium ions relocate with graphite. One usual method is X-ray diffraction, which shows how the spacing between graphite layers changes as ions enter. Another is electron microscopy, which gives a close-up view of the graphite surface area prior to and after biking. Electrochemical tests also disclose exactly how fast ions relocate and just how much energy is shed throughout billing. With this data, researchers fine-tune the graphite itself. They could include coatings, adjustment bit dimension, or mix in other carbon kinds like graphene. Some also check out different materials stemmed from lasting sources. For example, biomass-derived carbon supplies a greener course for anodes while still supporting good intercalation behavior. Even more details on environment-friendly choices can be found in this item about biomass-derived carbon materials.

What Are the Real-World Applications of Optimized Intercalation? .

Maximized lithium ion intercalation contributes in almost every tool that uses a rechargeable battery. Electric automobiles rely on it for lengthy driving varieties and fast charging. Smart devices and laptop computers need it to remain light-weight yet effective. Also grid-scale power storage systems depend upon secure intercalation to hold solar or wind power for later use. As need expands, so does the requirement for far better graphite anodes. Firms are currently looking past just performance– they desire batteries that are secure, sturdy, and recyclable. That brings us to one more key location: regrowth. Used battery anodes can occasionally be cleaned and reused, decreasing waste and expense. This connections directly into round economic situation initiatives in the battery sector. If you are curious regarding just how old batteries get a second life, look into this summary of anode product regeneration technology in power battery recycling.

FAQs Regarding Lithium Ion Intercalation in Graphite .

Can any type of carbon product replace graphite for lithium intercalation?

Not quickly. Graphite has an unique split framework that fits lithium ions ideal. Other carbons may store a lot more lithium, but they often swell way too much or weaken swiftly. That is why graphite continues to be the conventional despite decades of study right into options.

Does temperature level influence intercalation?

Yes, a whole lot. Cold temperatures slow down ion activity, making billing harder and raising the risk of lithium plating. Heats speed things up yet can harm the graphite or electrolyte gradually. Battery management systems try to keep points in a secure middle variety.

Why do some batteries lose capability after numerous cycles?

Each charge-discharge cycle creates tiny adjustments in the graphite. Layers may move, cracks can develop, or the solid-electrolyte interface (SEI) layer might expand also thick. All of this makes it harder for ions to move freely, reducing functional capability.

Is quick charging negative for intercalation?

It can be, otherwise taken care of correctly. Quick charging presses ions into graphite really promptly. If the rate is expensive, ions pile up at the surface area as opposed to spreading out evenly, bring about plating or mechanical tension. Smart charging algorithms aid avoid these issues by readjusting existing based upon temperature level and state of cost.

Are there brand-new kinds of graphite being established?

(Analyzing the Intercalation Dynamics of Lithium Ions in Graphite Layers)

Yes. Researchers are working with customized graphite with better porosity, surface treatments, or hybrid structures. Some integrate graphite with silicon to enhance ability, though silicon’s expansion stays an obstacle. Others focus on purer synthetic graphite for consistency and efficiency.