Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

What is graphite?

Graphite is an allotrope of carbon, a grayish-black, opaque solid. It is chemically stable, corrosion-resistant, and does not readily react with acids or alkalis.

It is classified into natural graphite and synthetic graphite. Natural graphite is a non-renewable resource derived from graphite deposits. Synthetic graphite can also be produced from raw materials such as petroleum coke and pitch coke through a series of processing steps.

It can be used as an anti-wear agent and lubricant. High-purity graphite is used as a neutron moderator in nuclear reactors. It is also used to manufacture crucibles, electrodes, brushes, dry cell batteries, graphite fibers, heat exchangers, coolers, electric arc furnaces, arc lamps, and pencil leads, among other things.

What is artificial graphite?

In a broad sense, all graphite materials obtained through organic carbonization followed by high-temperature graphitization can be called artificial graphite, such as carbon fiber, pyrolytic carbon, and foamed graphite.

In a narrow sense, artificial graphite usually refers to a blocky solid material made by using carbonaceous raw materials with low impurity content as aggregates and coal tar pitch as binders, through processes such as batching, kneading, molding, carbonization, and graphitization.

The development of artificial graphite

In the early 20th century, scientists began experimenting with mixing graphite powder with materials such as resin to prepare artificial graphite materials. These early artificial graphite materials had lower performance and stability, but they laid the foundation for subsequent research and development.

In the 1950s, the development of powder metallurgy technology provided a new approach to the preparation of artificial graphite. By mixing graphite powder with metal powder and then subjecting it to processes such as high-temperature sintering and compression molding, artificial graphite materials with high strength and high thermal conductivity can be prepared.

In the 1970s, the development of chemical vapor deposition technology made the preparation of artificial graphite more refined and complex. By decomposing graphite raw material gases at high temperatures and depositing them on the substrate surface, artificial graphite materials with high purity and high crystallinity can be prepared.

In recent years, with the development of nanotechnology and carbon nanotube technology, the performance and properties of artificial graphite materials have been further improved.

Why is it called “black gold”?

According to USGS statistics, in 2022, global natural graphite reserves totaled approximately 330 million tons, while production reached approximately 1.3 million tons. China’s natural graphite reserves were 52 million tons, accounting for 15.76% of global reserves; its natural graphite reserves were 850,000 tons, accounting for 65.38% of global production. This demonstrates that my country is a major producer of graphite. Since 2017, my country’s natural graphite production has grown for 5 consecutive years.

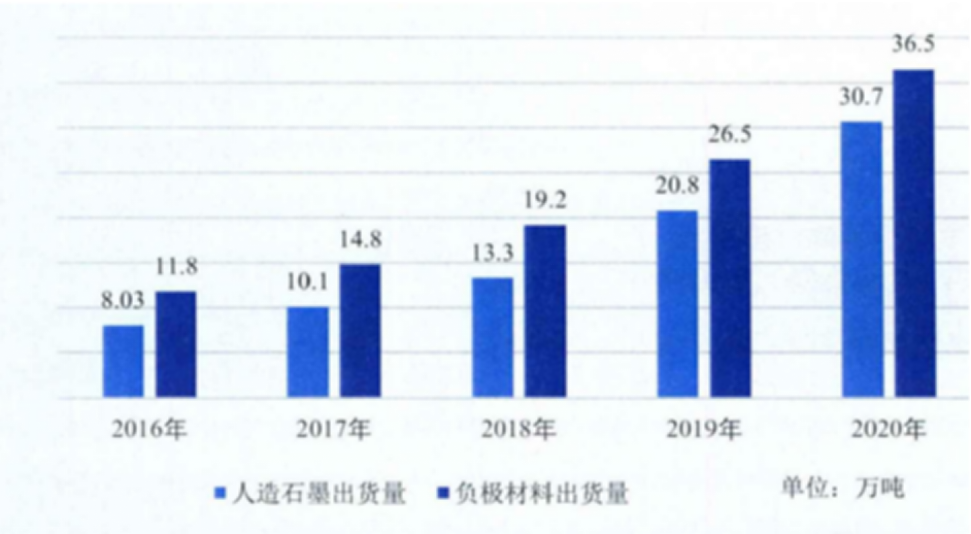

Because the development of natural graphite is still at a relatively low level, the industry needs further development and cannot meet the large demand for graphite in recent years from consumer products such as electronics and electric vehicles, as well as the metallurgical industry. In addition to the chemical stability and corrosion resistance widely possessed by graphite materials, synthetic graphite materials also have significant advantages such as excellent cycle performance, high-rate charge-discharge efficiency, and electrolyte compatibility, making them a mainstay of carbon materials. According to relevant forecasts, by 2050, the demand for synthetic graphite to replace natural graphite in the lithium-ion battery field will continue to increase.

Looking to the future, even “black gold” has its drawbacks.

From the perspective of the life cycle of artificial graphite materials, the production process of artificial graphite products generates many harmful waste gases and wastewaters, with gas pollution being the most significant.

Waste gases are generated because petroleum coke volatilizes during calcination, asphalt fumes are produced during the melting and roasting of asphalt, dust is generated during the crushing of raw materials such as petroleum coke and asphalt, and harmful gases such as NOx and SO2 are produced during roasting.

Furthermore, the production of raw materials such as petroleum coke and asphalt is energy-intensive, requiring the input of large amounts of crude oil and fossil fuels.

China’s 14th Five-Year Plan for Energy Conservation requires key industries such as chemicals to undergo green upgrades. By 2025, through the implementation of energy conservation and carbon reduction actions, the proportion of production capacity and data centers in key industries such as steel, electrolytic aluminum, cement, flat glass, oil refining, ethylene, synthetic ammonia, and calcium carbide reaching energy efficiency benchmark levels will exceed 30%.

The plan also promotes the clean and efficient use of coal, aiming to achieve a non-fossil energy share of approximately 20% of total energy consumption by 2026. The implementation of these policies presents significant challenges to the artificial graphite industry, placing higher demands on its energy conservation, emission reduction, and environmental friendliness.