Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

The Relationship In Between Battery Performance and Product Quality in Low-Temperature Environments

(The Relationship Between Battery Performance and Material Properties in Low-Temperature Environments)

What Is the Web Link In Between Battery Performance and Material Quality in Cold Conditions? .

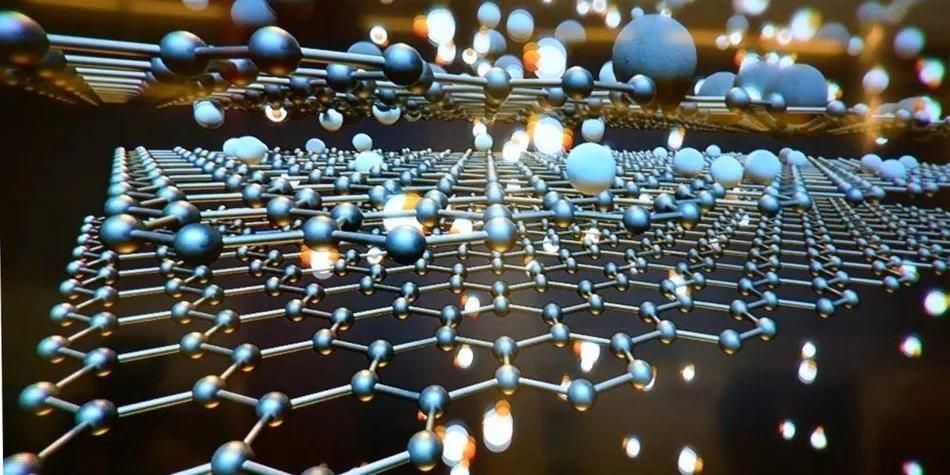

Batteries do not work also when it gets cold. This is not just a little problem. It impacts phones, electrical vehicles, and even power tools in winter season. The main factor depends on the materials inside the battery. Every part of a battery– its anode, cathode, and electrolyte– is made of details materials. These compounds act differently when temperatures go down. As an example, lithium-ion batteries make use of graphite anodes. At low temperature levels, lithium ions move much more slowly with the graphite structure. This reduces the whole charging and releasing procedure. The electrolyte also becomes even more viscous, like honey in the fridge. That makes it harder for ions to travel between electrodes. So, the efficiency decline you see in cold weather is truly a story about how materials reply to the cold. Recognizing this assists designers make much better batteries. You can learn more concerning anode habits under tension by looking into product research studies like those displayed in electron microscopy analyses of anodes.

Why Do Product Options Matter A Lot in Freezing Climate? .

Not all battery products handle chilly the same way. Some stand up far better than others. If you select the wrong product, your battery might stop working at simply a couple of degrees below zero. However if you select intelligently, it could keep going even in severe winter seasons. The key is how quickly ions can move and how stable the framework stays when it’s cool. Graphite, commonly utilized in anodes, has layered structures that can trap lithium ions when it’s as well cool. This results in issues like lithium plating, which damages the battery gradually. More recent products, like tough carbon or certain steel oxides, may provide much better low-temperature efficiency since their structures are more open or flexible. Also, the electrolyte mix matters a whole lot. Standard fluid electrolytes ice up or thicken, but some sophisticated formulations stay fluid. That’s why scientists spend a lot time checking different mixes. For insights into just how international requirements shape these choices, see the summary on certification systems for anode products.

Exactly How Can Designers Enhance Low-Temperature Battery Efficiency Via Materials? .

There are several wise ways to take care of cold-weather battery issues utilizing better products. One approach is to tweak the anode. Instead of pure graphite, engineers blend it with other carbon kinds or coat it with thin layers that assist ions move quicker. Another idea is to design electrolytes that do not get thick when cold. Including special solvents or salts can lower the cold factor. Some teams also try solid-state electrolytes, though those bring their own obstacles. Home heating the battery a little before usage is another trick, but that utilizes additional power. The best long-lasting repair is building the appropriate chemistry from the start. That implies choosing electrode materials that remain conductive and secure in the cold. It also suggests matching the anode and cathode so they interact efficiently even when it’s freezing. Study right into alternatives like sodium-ion batteries shows assurance right here as well. These utilize different products that might manage cool far better. Read more regarding this emerging tech in sodium-ion battery developments.

Where Are Low-Temperature Battery Solutions A Lot Of Required? .

Cold-weather battery performance is not just a convenience issue. It’s essential in many real-world applications. Electric vehicles in places like Canada, Scandinavia, or north China typically lose range in wintertime. Drivers discover slower billing and weak acceleration. That’s why carmakers test batteries in climate chambers that mimic Arctic conditions. Drones used for distribution or checking in hilly or polar regions also face this trouble. If the battery passes away mid-flight, the drone collisions. Military equipment, emergency devices, and exterior sensing units all depend on trustworthy power in cold temperatures. Also daily devices like mobile phones can close down throughout a ski journey. So, boosting battery materials for cool climates isn’t nearly much better specifications– it has to do with safety, integrity, and usability. Companies that understand this gain a large edge, specifically as clean energy and electrical transport grow worldwide.

What Prevail Inquiries Regarding Batteries and Winter? .

(The Relationship Between Battery Performance and Material Properties in Low-Temperature Environments)

Individuals often ask yourself why their phone passes away so quick in the snow. The solution is straightforward: cold reduces the chemical reactions inside. One more constant inquiry is whether leaving a device in a chilly automobile damages the battery. Short exposure normally does not create long-term damage, however duplicated deep cold cycles can use it out much faster. Some ask if heating the battery assists. Yes, but only delicately– never utilize straight warm like a hair dryer, as that can trigger fractures or leaks. Others want to know if all battery kinds endure the very same. No, lithium iron phosphate (LFP) batteries handle cold worse than some nickel-rich ones, yet they’re more secure total. Then there’s interest regarding future repairs. Will solid-state batteries address this? Perhaps, but they still have problem with ion movement at reduced temperatures. The bottom line is that material science holds the secret. Every little renovation in anode layout, electrolyte formula, or interface design brings us closer to batteries that work just as well in Alaska as they perform in Arizona.