Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Global Research Study Progression on the Compatibility of Anode Materials and Electrolytes

(Global Research Progress on the Compatibility of Anode Materials and Electrolytes)

The globe works on batteries. Think of your phone, your laptop, maybe your auto. All count on keeping energy successfully. Yet constructing much better batteries isn’t straightforward. A significant obstacle lies deep inside, right at the point where 2 vital components satisfy: the anode and the electrolyte. Their compatibility, exactly how well they collaborate securely over time, is vital. Allow’s explore the latest international research study pressing the borders of this critical relationship.

What is Anode Product and Electrolyte Compatibility? .

Photo a battery. It has a favorable end (cathode) and a negative end (anode). The anode is where energy gets kept throughout charging. Common anode materials consist of graphite, silicon, and even lithium metal itself. The electrolyte is the fluid or gel loading the area in between. It enables billed bits, ions, to move back and forth as the battery charges and discharges. Compatibility describes just how steady and participating this anode-electrolyte pair is. We desire them to engage smoothly without undesirable side responses. A great match means ions circulation easily during charging and discharging. The materials do not deteriorate rapidly. They do not create hazardous gases or trigger safety troubles like fires. It’s like a smooth chemical handshake that lasts for countless cycles. Poor compatibility suggests the handshake is weak or harmful. The anode might react badly with the electrolyte. This can form unpredictable layers. It can take in the electrolyte. It can reduce the battery’s life. It can even make the battery hazardous. Researchers globally are regularly trying to recognize these communications much better. They intend to find the most effective possible sets.

Why is Anode and Electrolyte Compatibility So Important? .

It comes down to performance, lifespan, and safety and security. These are the three columns of a great battery. Think about your phone battery dying rapidly after a year. That’s often connected to compatibility issues. When the anode and electrolyte aren’t well-matched, undesirable responses take place. These responses consume lithium ions. They consume electrolyte components. They create thick, repellent layers on the anode surface area. This directly lowers the battery’s ability. The battery holds less fee over time. It likewise enhances the interior resistance. Charging and discharging become slower. The battery heats up a lot more. Even worse still, these side reactions can be harmful. They could create gases creating swelling. They might develop problems for inner shorts. They could also cause thermal runaway and fire, especially with responsive products like lithium metal. Accomplishing excellent compatibility is vital for building batteries that last much longer, fee quicker, and are fundamentally safer. This is why scientists pour so much initiative right into fixing compatibility challenges.

Exactly How is Global Research Improving Compatibility? .

Scientists are assaulting the problem from numerous angles. One major emphasis is creating new electrolyte solutions. Conventional fluid electrolytes work well with graphite anodes however battle with others. For silicon anodes, which swell a lot, researchers are creating electrolytes that form a lot more stable safety layers. They are developing additives that secure the anode surface area. For lithium metal anodes, the divine grail for high power, the challenge is enormous. Lithium is very responsive. Solutions include extremely focused salts in the electrolyte. Solid-state electrolytes are another big area. These replace the liquid with a strong material. This can literally obstruct unwanted reactions. It can additionally prevent dendrite growth, hazardous spikes of metal that cause shorts. Coatings on the anode product itself are likewise crucial. Researchers use thin layers of protective materials. These layers imitate shield. They reduce straight contact in between the responsive anode and the electrolyte. They promote the development of better protective movies. Advanced devices aid as well. Scientists utilize powerful microscopic lens and computer system simulations. They see responses occur in real-time. They model communications at the atomic level. This deep understanding guides the design of far better products. It’s an international race to find the best mixes.

Applications Depending On Better Anode-Electrolyte Compatibility .

This isn’t simply laboratory work. Better compatibility drives real-world technology. Electric automobiles need batteries that last thousands of thousands of miles. They need quickly charging without damages. Excellent anode-electrolyte sets are essential for this. Next-generation EVs aim for longer arrays and much shorter charging stops. Smartphones and laptop computers require thinner, lighter batteries with longer life. Boosted compatibility assists achieve this. It permits the use of higher-energy anode materials like silicon. Renewable resource storage needs huge batteries that last decades. Steady anode-electrolyte systems reduce destruction over time. This makes grid storage much more affordable. Safety and security is vital in all these usages. Preventing fires in vehicles or homes depends heavily on compatible products. Solid-state batteries promise even better safety and energy density. Their success pivots totally on finding solid electrolytes that function perfectly with advanced anodes like lithium metal. The progression in compatibility research study directly enables these future applications.

Anode and Electrolyte Compatibility FAQs .

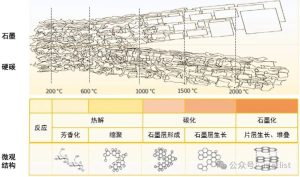

Why do graphite anodes function well with common electrolytes? Graphite is reasonably stable. It responds mildly with basic liquid electrolytes. This reaction creates a protective layer called the SEI. This layer permits lithium ions in and out but blocks even more significant responses. This provides graphite good cycle life. Yet graphite has actually restricted energy storage ability.

What issues do silicon anodes face? Silicon can keep a lot more lithium than graphite. This implies potentially greater energy batteries. But silicon swells greatly when it absorbs lithium. This swelling splits the protective SEI layer. Fresh silicon surface keeps getting revealed. It responds with the electrolyte constantly. This eats lithium and electrolyte. Battery capacity fades rapidly. Scientists fix this by creating tougher SEI layers. They make use of unique electrolyte additives. They develop silicon particles and structures to take care of the swelling much better.

Why is lithium metal so challenging? Lithium metal provides the highest theoretical power density. It’s the best anode material. However it’s very reactive. It responds strongly with the majority of liquid electrolytes. It forms uneven, mossy down payments and harmful dendrites during charging. These dendrites can puncture the separator. This causes inner short circuits and fires. Solutions involve strong electrolytes that obstruct dendrites. Extremely stable fluid electrolytes are likewise being developed. Protective coverings on lithium metal aid as well.

What are solid-state electrolytes? These are solid materials that carry out lithium ions. They replace the fluid electrolyte. The large hope is they stop lithium dendrites. They might also enable lithium steel anodes securely. They commonly persuade a broader temperature level variety. They are non-flammable, increasing safety. But making them conduct ions as well as fluids is hard. Making sure excellent call with both the anode and cathode is challenging. Research is extreme on discovering the ideal strong materials and making them work effectively.

(Global Research Progress on the Compatibility of Anode Materials and Electrolytes)

Just how does compatibility influence battery charging speed? Quick billing presses a great deal of lithium ions into the anode rapidly. If the anode-electrolyte user interface is unpredictable, this can be tragic. It can trigger lithium plating on the anode surface area. It can accelerate side responses. It can produce excessive heat. Good compatibility enables ions to move in and out efficiently also at high prices. A steady SEI layer is critical. It should enable fast ion transport without breaking down. Electrolytes made for fast billing frequently contain ingredients that strengthen this layer. Compatibility is crucial for the fast-charging batteries all of us want.