Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

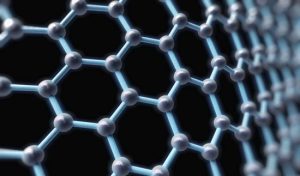

Graphite. It may sound straightforward, just carbon truly. However worldwide of batteries, particularly lithium-ion batteries powering our phones, automobiles, and a lot more, graphite is a super star. It’s the key product inside the battery’s unfavorable electrode, the anode. Exactly how this graphite is prepared, specifically just how it’s milled and classified, plays a big role in exactly how well your battery carries out. Let’s explore how this behind the curtain technology shapes your battery’s life.

(How Graphite Milling and Classification Technology Affects Battery Performance)

1 What is graphite milling and category innovation? .

Think about baking a cake. The appearance of your flour matters. Great flour makes a smooth cake, rugged flour makes it abrasive. Graphite milling and classification modern technology resembles preparing the ‘flour’ for your battery. It begins with raw graphite, often extracted from the planet. This raw graphite isn’t all set for battery use. It needs handling.

Milling is the step where we damage down the big portions of graphite into smaller sized particles. Equipments grind or squash the graphite. Picture tiny hammers striking the graphite over and over until it obtains smaller sized. Category follows. After milling, the graphite particles are all different sizes. Category types them. It separates the great powder from the coarser little bits. Consider a filter trembling flour; the fine things undergoes, the lumps remain behind. In sophisticated category, equipments utilize air or other methods to arrange bits exactly by shapes and size. The objective is to get graphite powder with simply the best particle attributes for making battery anodes.

2 Why is graphite milling and category technology important? .

Not all graphite powder is equivalent. The way it’s milled and identified straight impacts the battery’s essential attributes. Right here’s why it’s so important:.

Initially, fragment dimension affects just how much power the battery can store. Smaller bits imply even more surface. Even more area suggests more places for lithium ions to acquire throughout billing. This converts to higher battery ability. You desire your phone to last longer? You need well-milled graphite.

Second, particle sizes and shape distribution matter for billing speed. Attire, rounded particles allow lithium ions to move in and out more easily. If particles are jagged or too huge, ions battle. Smooth, regular bits imply quicker charging. No one suches as waiting hours for their phone to charge.

Third, the procedure influences battery life and security. Badly crushed graphite could have sharp edges. These edges can jab through the slim separator inside the battery, causing a short circuit. That’s dangerous. Consistent particle size likewise helps the graphite pack equally inside the anode. This protects against stress factors that can fracture gradually. Longer battery life originates from cautious milling and category.

3 How does graphite milling and category technology work? .

Making battery-grade graphite is an accurate procedure. It’s not simply shattering rocks. Different methods attain various results.

Milling methods vary. Some make use of mechanical force. Sphere mills are common. These are large drums full of tough balls. Graphite chunks and spheres topple together. The spheres crush the graphite right into powder. Jet milling is one more technique. It uses high-speed jets of air. Fragments collide at high speed and break apart. This often generates finer, smoother bits than round milling. The selection depends upon the desired last bit size and shape.

Category is equally crucial. Air classifiers are often utilized. They blow air through the milled graphite powder. Lighter, smaller particles get brought further by the air stream. Larger, larger fragments befall faster. This divides them by dimension. Advanced classifiers can arrange particles really precisely. They may make use of several stages or special designs. The goal is a limited circulation. This indicates most bits are extremely near to the target size. Few bits are too huge or as well small. Getting this distribution right is vital forever battery efficiency. The whole procedure, milling and category, needs cautious control. Speed, airflow, temperature, and device settings all matter. Even little changes can modify the graphite powder high quality.

4 Where is graphite milling and classification technology applied? .

This innovation is important for making the batteries we use everyday. It goes to the heart of lithium-ion battery manufacturing.

Electric cars depend heavily on it. EV batteries need high capability and rapid charging. Attaining this requires exactly machine made graphite anodes. The graphite particles have to be little for high power density. They must also be smooth and consistent for quick ion movement. Without sophisticated milling and classification, EVs wouldn’t have the array or charging rate they do.

Our smart devices, laptop computers, and tablets depend on it too. These tools require small, long-lasting batteries. Penalty, consistent graphite powder enables manufacturers to pack more energy right into smaller areas. It likewise makes certain steady performance over numerous cost cycles.

Power storage systems likewise profit. Huge batteries storing solar or grid power need reliability and long life. Appropriately processed graphite anodes contribute to this. They aid the battery hold up against repeated deep charging and releasing. The technology is regularly developing. Scientists are pushing for even better particle control. They wish to unlock far better battery efficiency. Milling and category advancements will certainly belong to future breakthroughs.

5 Regularly asked concerns about graphite milling and category technology .

Individuals usually have inquiries about this specialized process.

Does better graphite always mean a much better battery? Not necessarily. Very fine fragments can be difficult. They could clump together. They can respond more with the battery electrolyte. This might really injure efficiency or security. Locating the perfect particle size is critical. It’s an equilibrium.

Is this technology expensive? Yes, advanced milling and category devices is pricey. Precise devices need considerable investment. Running them likewise calls for energy and proficiency. This adds to the total expense of battery production. However the efficiency benefits usually validate the cost for top quality batteries.

Can other products replace graphite? Research study is continuous. Silicon reveals promise for higher ability. Yet silicon increases a great deal during charging. This creates problems. Graphite remains the dominant anode product today. Its handling is well-understood. Improving graphite milling and classification is crucial in the meantime.

Just how do manufacturers ensure uniformity? Strenuous quality assurance is essential. They frequently examine the graphite powder. They measure fragment dimension circulation, form, and surface area. Automated systems check the milling and category devices. This assists preserve the specific specs required for reputable batteries. Small variants can result in big distinctions in battery sets.

(How Graphite Milling and Classification Technology Affects Battery Performance)

What’s the future of this innovation? Anticipate extra accuracy. Makers will get better at regulating fragment size and shape. New milling strategies might arise. Classification can become a lot more accurate. The goal continues to be the very same. Generate graphite powder that takes full advantage of battery power, rate, life, and safety and security. This covert innovation will certainly maintain powering our world.