Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Debunking the Filtration and Spheroidization Refine of All-natural Graphite .

(Demystifying the Purification and Spheroidization Process of Natural Graphite)

Natural graphite is a superb material. It conducts electricity. It handles heat well. It’s slippery smooth. But right out of the ground, it’s not ideal for many sophisticated usages. It requires a makeover. That’s where purification and spheroidization can be found in. Think about it like improving a harsh diamond. We take the raw graphite. We cleanse it up. We form it. We make it prepared for action. Allow’s pull back the curtain on these critical processes.

1. What is Purification and Spheroidization? .

First, filtration. Visualize graphite fresh from the mine. It has contaminations. These are things like ash, silica, or various other minerals mixed in. Purification gets rid of these undesirable components. It cleans the graphite. The objective is to get graphite that is virtually pure carbon. This makes it far better at carrying out electricity and warmth.

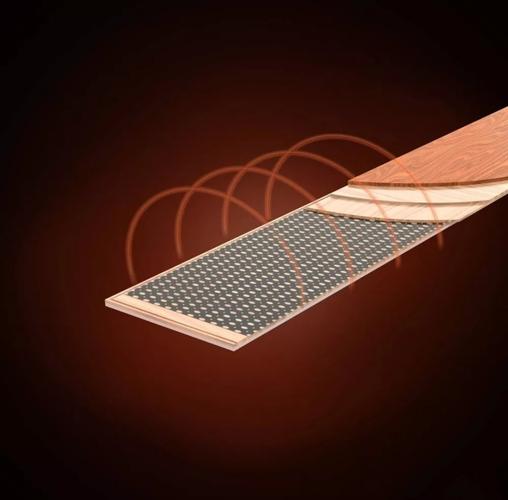

Next off, spheroidization. All-natural graphite flakes are level. They look like little cornflakes under a microscopic lense. This shape isn’t excellent for some applications, specifically batteries. Spheroidization modifications that. It changes those flat flakes right into little round spheres. Think about marbles as opposed to shards of glass. This procedure entails unique techniques. We grind the flakes. We shape them under controlled problems. We turn them into spheres. These graphite balls compact much better. They flow more smoothly. They boost performance in items like lithium-ion batteries.

2. Why Purify and Spheroidize Natural Graphite? .

Why bother? Why not utilize graphite as it is? The solution is efficiency. Pollutants are bad news. They conflict. They lower conductivity. They can create undesirable chain reaction. Purified graphite functions better. It lasts much longer. It’s even more reliable popular applications.

The level shape of all-natural flakes causes issues too. In a battery, graphite is used in the anode. Level flakes don’t pile effectively. They leave spaces. They create irregular surfaces. This makes it harder for lithium ions to move in and out throughout billing and discharging. It limits battery ability. It can even reduce battery life. Spheroidization repairs this. The round bits load firmly. They create a consistent surface. This enables lithium ions to relocate efficiently. It boosts the battery’s energy thickness. It improves how quick the battery can charge and release. It makes batteries a lot more powerful and longer-lasting. Essentially, purification and spheroidization turn normal graphite right into a high-performance product.

3. Exactly how Does Filtration and Spheroidization Work? .

So, how do we actually do it? Allow’s break it down detailed.

Purification techniques differ. One usual means is chemical filtration. We use strong acids, like hydrofluoric acid. The acid liquifies the impurities. It leaves the graphite. Another method is thermal purification. We warm the graphite to very high temperatures. We’re chatting thousands of degrees Celsius. At these temperatures, contaminations burn off or vaporize. The graphite remains. Often, we integrate both approaches. We might do a chemical therapy initially. After that we follow it with high heat. The option depends upon the beginning product. It relies on the pureness level we require.

Spheroidization is a mechanical procedure. It entails specialized makers. Consider high-energy mills or effect mills. We feed the graphite flakes right into the mill. Inside, powerful pressures act on the flakes. They obtain struck. They obtain compressed. They get sheared. This breaks down the flakes. It rounds off the sharp sides. It progressively forms the fragments right into spheres. We manage the milling problems carefully. We manage the power. We control the time. We manage the atmosphere. This ensures we obtain the appropriate size. We get the right form. We get the perfect ball. After milling, we might include a finishing. This assists the balls circulation also better. It safeguards them. It improves their performance in the final application.

4. Applications of Detoxified and Spheroidized Graphite .

Where do we utilize this updated graphite? Its main star function remains in lithium-ion batteries. The anode product needs to be excellent. Cleansed and spheroidized graphite is best here. Its high purity ensures good electrical contact. It reduces side responses. The round form allows thick packing. This maximizes energy storage space per volume. It makes sure secure biking efficiency. Virtually every smartphone, laptop, and electrical automobile depends on this refined graphite in its battery.

However batteries aren’t the only program in community. This special graphite is likewise terrific for conductive plastics and polymers. We mix it into plastics. This makes the plastic conduct electricity. We use this for anti-static packaging. We utilize it for electro-magnetic shielding. The spherical fragments mix uniformly. They produce good paths for electrical energy to circulation.

It’s used in advanced lubricants as well. Graphite is normally unsafe. The round fragments imitate tiny ball bearings. They lower rubbing. They aid things move smoothly, even under high pressure or temperature. Some greases and strong lubricants contain it.

Fuel cells additionally benefit. Graphite elements need high purity. They require excellent conductivity. Detoxified graphite supplies this. Even specific types of powder metallurgy utilize it. We include it to metal powders. It improves just how the metal streams during pushing. It can enhance the buildings of the final sintered part. In short, whenever high purity, excellent conductivity, and regular bit shape are required, detoxified and spheroidized graphite is often the best product.

5. Frequently asked questions regarding Filtration and Spheroidization .

Allow’s deal with some common questions people have.

Q: Can not we just use artificial graphite rather?

A: Synthetic graphite is made from oil coke. It’s very pure. It usually has a much more rounded form normally. However it’s likewise far more expensive. It takes a great deal of energy to make. Natural graphite is cheaper. It’s even more bountiful. Handling natural graphite with filtration and spheroidization offers us a material that executes virtually as well as synthetic. Usually, it’s a better price choice. Numerous battery manufacturers make use of a blend.

Q: Does spheroidization damage the graphite?

A: The milling procedure is intense. Yet it’s regulated. Good spheroidization intends to transform the form. It aims to reduce damage to the graphite crystal framework inside. The inner layers need to still be well-ordered. This protects the great conductivity. Effectively done, spheroidization improves overall performance. It does not ruin the graphite.

Q: Just how pure does the graphite requirement to be?

A: It relies on the application. For lithium-ion battery anodes, we require extremely high pureness. Usually, over 99.9% carbon is required. Lower pureness causes even worse battery life. It can cause security problems. For various other uses, like some lubricants or plastics, slightly lower pureness could be acceptable. Yet high pureness is constantly far better for efficiency.

Q: Are the spheres all the same dimension?

A: We regulate the process to get a certain size range. The particles aren’t all similar. But they fall within a controlled distribution. For batteries, a common size might be between 5 and 20 micrometers in size. Consistency is vital for loading thickness.

Q: Is this process eco-friendly?

(Demystifying the Purification and Spheroidization Process of Natural Graphite)

A: This is a large worry. Chemical purification utilizes rough acids. Handling and disposal are essential. Thermal filtration uses a great deal of power. The industry is dealing with greener approaches. We are establishing closed-loop systems for acids. We are taking a look at much more efficient heating modern technologies. Utilizing natural graphite refined in this manner can be better than synthetic overall. However it’s a location needing consistent renovation.