Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Here is the rewritten title and blog post:

(Preparation And Performance Research Of New Sodium Battery Composite Materials)

Unlocking the Future: The Power of New Sodium Battery Composites

The race for better batteries is on. We need them for electric cars, storing renewable energy, and powering our gadgets. Lithium-ion batteries have ruled for years. But they face problems. Cost, safety worries, and scarce materials are big issues. That’s where sodium batteries step in. Sodium is everywhere, cheap, and safer. The latest buzz is around sodium battery composite materials. These new materials could change the game. They promise longer life, faster charging, and lower costs. This blog dives deep into these exciting composites. We explore what they are, why they matter, how they’re made, where they’ll be used, and answer key questions.

1. What Are Sodium Battery Composite Materials?

Think of a composite material like a cake. It mixes different ingredients to make something better. Sodium battery composites work the same way. They combine various materials to improve battery performance. Usually, they blend active materials, conductive agents, and binders. Active materials store energy. Conductive agents help electricity flow. Binders hold everything together. The goal is simple. Make a battery that charges fast, lasts long, and stays safe. Researchers experiment with many combinations. Some use layered oxides. Others try phosphates or organic compounds. Mixing these materials creates new properties. The composite becomes stronger than any single part. It tackles weaknesses head-on. For example, pure sodium metal might react badly. Blending it with carbon can fix that. These composites are the rock stars of next-gen batteries.

2. Why Focus on Sodium Battery Composites?

Lithium batteries are good. But they have limits. Lithium is expensive and hard to find. Mining it causes environmental harm. Safety is another concern. Overheating can lead to fires. Sodium solves these problems. Sodium is abundant. It’s found in salt, making it cheap and easy to get. Sodium batteries are generally safer. They don’t catch fire as easily. So why composites? Because pure sodium materials aren’t perfect yet. They might fade quickly or charge slowly. Composites fix these issues. Combining materials boosts energy density. This means more power in the same size. Composites improve stability. The battery lasts longer through many charge cycles. They enhance conductivity. Electricity flows better for faster charging. Using composites makes sodium batteries truly competitive. They can match or beat lithium batteries on cost, safety, and performance. That’s a huge win.

3. How Are These Composite Materials Made?

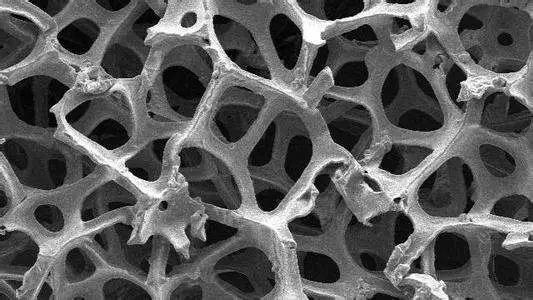

Making these composites is like advanced cooking. Scientists carefully prepare and mix the ingredients. First, they choose the base materials. These could be sodium-based compounds. Then they add things like carbon nanotubes or special polymers. The mixing process is crucial. It must be very precise. One common method is ball milling. This grinds materials together into a fine powder. Another method is wet chemistry. Materials dissolve in liquids and react. After mixing, the composite powder is processed. Sometimes it’s coated onto metal foils. This creates the battery electrode. Testing follows immediately. Scientists check the material’s structure. They use microscopes and X-rays. Then they build small test batteries. They charge and discharge these batteries hundreds of times. They measure speed, capacity, and lifespan. The best recipes go forward. Scaling up production is the next challenge. Factories need efficient ways to make large amounts. Quality control must be strict. Every batch must perform perfectly.

4. Where Will Sodium Battery Composites Be Used?

These composites aren’t just lab curiosities. They have real-world jobs waiting. Electric vehicles are a major target. EVs need affordable, safe batteries with long range. Sodium composites could provide that. They are cheaper than lithium. They are less likely to overheat. This makes cars safer and more accessible. Grid energy storage is another big area. Solar and wind power need storage for cloudy or calm days. Sodium batteries are perfect here. They cost less per stored watt-hour. Their safety suits large installations near homes. Composites make them last decades. Consumer electronics also benefit. Imagine phones charging in minutes. Or laptops lasting all day on a single charge. Sodium composites could make this happen. They are suitable for power tools, electric bikes, and scooters. Even large-scale backup power for hospitals uses them. The applications are vast. Wherever energy storage is needed, sodium composites will play a role.

5. FAQs About Sodium Battery Composites

(Preparation And Performance Research Of New Sodium Battery Composite Materials)

People have questions about this new tech. Let’s tackle the common ones. Are sodium batteries as good as lithium? Not yet, but composites are closing the gap fast. They offer similar performance at lower cost. Plus, they are safer. When will we see them in products? Prototypes exist now. Mass production is starting. Expect commercial products within the next few years. Electric cars might adopt them first. Are they environmentally friendly? Yes, much more than lithium. Sodium is abundant and easy to extract. Recycling processes are also simpler. What about charging speed? Composites significantly improve this. New designs allow very fast charging. Some prototypes match lithium speeds. Is safety really better? Absolutely. Sodium batteries operate at lower voltages. They are less reactive. Composites add extra stability layers. Thermal runaway events are far less likely. This makes them safer for homes and vehicles.