Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Opening the Power: Making Lithium Batteries Cost Faster and Last Longer .

(Optimization Of Charge And Discharge Performance Of Lithium Battery Materials)

Ever waited hours for your phone to bill? Felt your laptop battery die right before conserving important work? Or worried concerning how long an electric car takes to power up? The secret lies deep inside the battery itself, in the lithium battery materials . Enhancing how these materials take care of charging and discharging isn’t simply technical jargon. It’s the key to powering our future quicker, more secure, and much more efficiently. Allow’s dive into this important world.

1. Exactly What is Cost and Discharge Efficiency Optimization? .

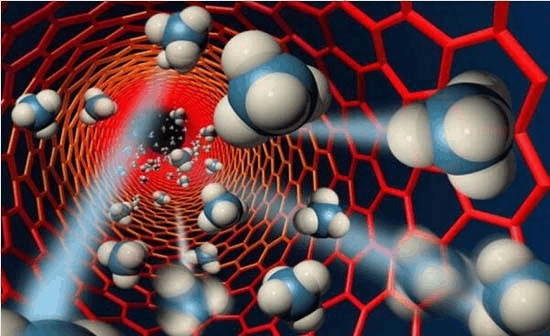

Consider a lithium battery like a tiny chemical stockroom. Billing relocations lithium ions out of storage (the cathode) through a liquid highway (the electrolyte) into another storage space device (the anode). Releasing sends them when you require power. Lithium battery products are the core elements– the cathode, anode, electrolyte, and separator– enabling this activity.

Maximizing cost and discharge efficiency means making this whole process better. We want batteries that:.

Fee Faster: Obtain even more energy right into the battery in much less time.

Discharge More Power: Deliver more powerful bursts of energy when needed (like accelerating an EV).

Last Longer: Deal with even more charge/discharge cycles before wearing.

Be Safer: Prevent getting too hot, brief circuits, or damage during fast billing or high power needs.

Be Even more Reliable: Shed much less energy as warm throughout charging and releasing.

It’s about pressing the lithium battery products to function harder, smarter, and longer without breaking down. This optimization straight translates to the efficiency you feel in your tools and lorries.

2. Why Optimizing Lithium Battery Products Matters So Much .

This isn’t almost ease; it’s crucial for almost every innovation we rely upon now and in the future.

Electric Vehicles (EVs): Faster charging methods much less waiting at terminals. Better discharge performance means quicker velocity and longer range. More cycles indicate the battery pack lasts as lengthy as the auto itself. Without optimized lithium battery products , extensive EV adoption stalls.

Portable Electronic devices: We require thinner phones, longer-lasting laptop computers, and powerful tablets. Faster charging and higher power density (even more power in a smaller room) rely completely on superior materials. No one desires a phone that passes away by lunch.

Renewable Resource Storage Space: Solar and wind power are intermittent. We require large batteries to save excess energy for usage when the sunlight isn’t beaming or wind isn’t blowing. Maximized materials imply these grid-scale batteries bill effectively from renewables, discharge accurately to power homes, and last for years– making environment-friendly power absolutely sensible.

Safety and security First: Pressing batteries tough boosts risks. Maximizing materials enhances security, reduces the opportunity of thermal runaway (fire), and builds in safety attributes inherently. This is non-negotiable.

Expense Reduction: Much better efficiency and longer life imply the cost per kilowatt-hour of kept power declines. This makes batteries more affordable for everybody, from customers to energy companies.

Simply put, maximizing lithium battery products is the engine driving the electrification of everything.

3. Exactly How Researchers Are Turbocharging Lithium Battery Materials .

So how do researchers make these products perform better? It’s a continuous fight fought on numerous fronts:.

Cathode Crafting: Developing new cathode materials (like high-nickel NMC, lithium iron phosphate LFP, or emerging lithium-rich oxides) that hold more lithium ions or enable faster movement. Surface finishings protect the cathode and make reactions smoother.

Anode Improvements: Improving graphite anodes or checking out choices like silicon. Silicon can hold much much more lithium, enhancing capacity dramatically. Yet silicon swells a great deal during charging, triggering cracks. Scientists tackle this with nano-engineering (small silicon fragments), special binders, and smart structures to handle the expansion.

Electrolyte Design: Creating much better electrolytes– the liquid or gel ions take a trip via. This includes producing ingredients that develop a steady, protective layer (the SEI) on the anode much faster. It additionally suggests developing new salts and solvents that work at higher voltages (for more power) and are less combustible (for safety), especially for fast charging.

Separator Smarts: Enhancing the separator– the thin film maintaining anode and cathode apart. New separators shut down if they obtain too hot, stopping fires. Others are coated to enhance electrolyte flow and ion activity.

Nano-Structuring: Engineering materials at the nanoscale (billionths of a meter). Producing little particles or special permeable structures offers lithium ions shorter, much easier paths to travel. This considerably speeds up charging and discharging.

User interface Focus: Extremely examining and boosting the user interfaces where materials meet– like in between the electrode fragments and the electrolyte. A secure, low-resistance user interface is essential for quick ion circulation and lengthy life.

It’s a complex challenge. Improving one material usually influences others. Researchers regularly stabilize efficiency gains versus price, safety and security, and manufacturability.

4. Where You See Enhanced Lithium Battery Materials at work .

The outcomes of maximizing lithium battery products aren’t hidden in laboratories. They’re powering your daily life:.

Your Smartphone: Rapid charging (like 0-50% in 15 mins) relies on innovative anode products (like silicon-graphite blends) and stable electrolytes. Longer battery life in between charges originates from higher power density cathodes.

Your Laptop computer & Tablet Computer: Slimmer layouts and all-day battery life are straight results of optimized materials loading more energy right into less room. Quick top-up charging is another benefit.

Electric Cars (EVs): The most up to date EVs flaunt ranges over 300 miles. They can bill from 10% to 80% in 20-30 minutes utilizing effective DC rapid battery chargers. This requires cathodes steady at high voltages, anodes that accept lithium swiftly, and electrolytes that do not damage down under stress. High discharge rates allow rapid acceleration.

Power Tools: Cordless drills and saws need high power result for bursts of energy. Enhanced products supply solid discharge performance without overheating.

Electric Bikes & Scooters: Light-weight batteries with great variety and quick recharge times make micro-mobility useful.

Grid Storage: Large battery setups saving solar and wind energy use durable, long-life lithium battery products (commonly LFP for its safety and security and cycle life) to bill and discharge daily for many years.

Medical Tools: Pacemakers and various other implants require exceptionally reliable, lasting, and safe batteries– pressing material optimization to the extreme.

Every leap in battery performance you experience traces back to advancements in these core products.

5. Lithium Battery Product Optimization: Your Questions Responded to .

Allow’s deal with some usual concerns:.

Q: Does “faster charging” hurt my battery? A: It can if not done right. Criterion billing is gentler. Real quick charging requires specific lithium battery products crafted to manage the anxiety (like stable anodes and protective electrolytes). Making use of a manufacturer-approved quick charger with a suitable tool is key. Prevent inexpensive chargers.

Q: Why can’t we just make batteries charge in 5 mins? A: Physics and chemistry are tough! Moving lithium ions incredibly quickly creates substantial warm. Existing products and security limitations prevent risk-free 5-minute complete costs for huge batteries. Scientists are striving on brand-new materials (like super-fast billing anodes) and thermal management to press these limitations.

Q: My old phone battery dies swiftly. Did the products wear? A: Yes, exactly. Deterioration occurs over cycles. Lithium gets caught, internal resistances develop, the safety layers damage down. Enhancing materials aims to significantly slow this degradation, making batteries last many more years.

Q: Are new battery materials secure? A: Security is vital. New materials undertake rigorous testing. While new chemistries (like higher nickel cathodes) can be extra reactive, optimization focuses greatly on improving safety via coverings, additives, better separators, and thermal administration systems. Much safer chemistries like LFP are additionally extensively made use of.

(Optimization Of Charge And Discharge Performance Of Lithium Battery Materials)

Q: What’s the most significant challenge now? A: Balancing act. Getting considerably greater power density (longer range), much quicker charging, longer life time (countless cycles), improved safety, and lower expense– all at the exact same time. Developments typically improve one or two elements yet present obstacles in other places. Solid-state batteries are a promising following step intending to resolve a lot of these challenges with each other.