Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Hard Carbon: The Secret Superstar Powering Tomorrow’s Batteries .

(Application Research Of Hard Carbon In Electrochemical Energy Storage Devices)

We hear a great deal about lithium-ion batteries. They’re in our phones, laptop computers, and electric autos. But a peaceful change is making inside labs worldwide. The principal? Difficult Carbon . This special material is swiftly coming to be the best selection for next-generation energy storage. Allow’s dive into why hard carbon is creating such a mix.

1. What Exactly is Hard Carbon? .

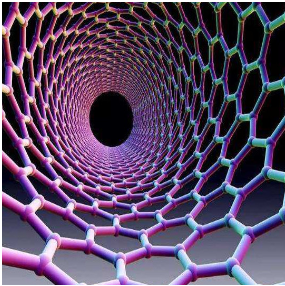

Think about graphite. It’s the smooth, split carbon found in routine lithium-ion batteries. Difficult carbon is graphite’s rougher, more complex cousin. Scientists call it “non-graphitizable carbon.” The name gives a hint. Unlike graphite, hard carbon rejects to develop those cool, orderly layers also when heated to very high temperatures. Its structure is untidy. It has great deals of small pores, defects, and a disordered arrangement of carbon atoms. Think of a heap of messed up paper versus nicely piled sheets.

This unpleasant structure is actually its superpower. Those spaces and crannies produce space. Area is essential for keeping various types of ions, specifically bigger ones like salt. Difficult carbon is usually made from things abundant in carbon yet that do not easily become graphite. Assume biomass like coconut shells, wood, and even specific plastics. The raw material and exactly how you heat it (a procedure called pyrolysis) actually shape hard carbon’s last residential or commercial properties. This adaptability is a big plus.

2. Why Does Hard Carbon Issue A Lot Right Now? .

Batteries encounter large obstacles. We need more energy storage for sustainable power grids. We require less expensive electrical automobiles. We need much safer tools. Hard carbon deals with a number of issues head-on.

First, it’s a champ for sodium-ion batteries. Lithium is terrific, yet it’s pricey and not located everywhere. Salt is cheap and bountiful, like table salt. The problem? Sodium ions are bigger than lithium ions. Graphite’s limited layers struggle to hold them successfully. Tough carbon’s disordered framework and pores are ideal. They offer a lot of space for salt ions to slip in and out easily. This makes sodium-ion batteries a real, economical option.

Second, difficult carbon can potentially bill quicker. The open structure allows ions to move much more easily. Consider driving on a wide-open highway versus a narrow, jampacked road. Faster charging is a huge bargain for electric cars and gizmos.

Third, it can be safer. Lithium metal plating is a major fire danger in fast-charging lithium-ion batteries. Difficult carbon can aid stop this hazardous plating. Its framework motivates ions to park securely within the carbon itself. Ultimately, making hard carbon commonly makes use of waste materials. Utilizing coconut shells or timber waste is much greener than mining graphite. Sustainability is essential.

3. Exactly How is Hard Carbon Made and Tuned for Batteries? .

Making high-performance difficult carbon isn’t practically shedding stuff. It’s a cautious science. The process usually starts with a “forerunner”– the raw product. Typical choices are:.

Biomass: Coconut shells, wood chips, nut shells, also corn cobs. These are sustainable and frequently waste items.

Polymers & Resins: Specific plastics or artificial materials can be designed to give details carbon frameworks.

Fossil Fuels: Pitch or coal tar can be utilized, though less lasting.

The magic takes place during pyrolysis. This means heating the forerunner in a heating system with little or no oxygen. Oxygen would certainly just melt it to ash. Rather, without oxygen, the product decomposes, launching gases and leaving behind primarily carbon. However it’s not just one temperature. The heating rate, the last temperature (usually 1000-1600 ° C), and for how long it remains warm all matter. These actions manage the final structure– just how disordered it is, how many pores it has, and exactly how huge those pores are.

Scientists don’t stop there. They commonly “turn on” the difficult carbon. This suggests treating it with chemicals (like potassium hydroxide) or heavy steam at high temperatures. Activation develops a lot more small pores, boosting the surface considerably. Even more surface area means even more places for ions to park, enhancing capability. Sometimes, they dope the carbon. This implies including small quantities of other aspects like nitrogen, sulfur, or phosphorus into the carbon framework. Doping can alter exactly how the carbon connects with ions, making it even much better at storing them.

4. Where is Hard Carbon Being Made Use Of? (Past the Evident) .

Sodium-ion batteries are the brightest spotlight for tough carbon now. Business are racing to advertise them. Hard carbon anodes are the important part making this feasible. Expect to see them soon in:.

Affordable Electric Cars: Making EVs more affordable for even more people.

Grid Power Storage Space: Storing solar and wind power for when the sun isn’t beaming or the wind isn’t blowing. Price and safety are essential right here.

Customer Electronic Devices Back-up Power: Like uninterruptible power products (UPS) for homes or companies.

Yet hard carbon isn’t limited to sodium. It’s discovering functions in innovative lithium-ion batteries as well. For applications needing super-fast charging, like power devices or some EVs, difficult carbon anodes can outperform graphite. Its capacity to take care of quick charging without lithium plating is a large security and efficiency benefit. Tough carbon is also being discovered in lithium-sulfur batteries and also in potassium-ion batteries, an additional potential option to lithium.

5. Hard Carbon FAQs: Your Burning Concerns Answered .

Is tough carbon changing graphite entirely? No, not. Graphite is still king for common lithium-ion batteries because of its high capability and maturity. Hard carbon is the expert. It’s vital for sodium-ion and exceptional for particular high-power or fast-charging lithium-ion applications. They complement each various other.

Is hard carbon more pricey than graphite? Presently, yes, usually due to smaller-scale manufacturing and handling prices. But rates are anticipated to go down considerably as manufacturing ranges up, especially utilizing economical biomass precursors. Its usage in cheaper sodium-ion systems also offsets the anode expense.

What are the downsides of tough carbon? Hard carbon anodes generally store somewhat less lithium per gram than graphite. They can likewise have a reduced initial performance. This means more lithium is lost throughout the first charge cycle. Researchers are striving to boost both ability and preliminary effectiveness with much better products and processing.

How lasting is tough carbon manufacturing? Using biomass waste is very sustainable. It provides worth to product that might otherwise be discarded. Procedures using nonrenewable fuel source precursors are less environment-friendly. The power utilized in high-temperature pyrolysis is additionally a factor. In general, the sustainability tale is usually positive, especially with biomass paths.

(Application Research Of Hard Carbon In Electrochemical Energy Storage Devices)

When will I see items with hard carbon batteries? Sodium-ion batteries utilizing hard carbon anodes are already going into the marketplace. Companies like CATL have revealed products. Expect broader adoption in energy storage space and possibly some EVs over the next couple of years. Fast-charging lithium-ion variations using difficult carbon could appear in niche applications faster. The future is arriving fast.