Professional graphite material supplier, graphite for EV, grease, furnace and any other industries.

Title: Silicides: The Ace In The Hole Against Rust .

(Application Of Silicides In Anti-Corrosion Materials)

Rust is a relentless enemy. It eats away at bridges, deteriorates pipelines, and damages machinery. Fighting it sets you back markets billions each year. But what if we had a concealed champ in this battle? Go into silicides. These special compounds, blending silicon with metals like titanium or chromium, are verifying to be effective allies in creating materials that laugh despite rust and decay. Allow’s discover exactly how silicides are changing the game.

1. Just What Are Silicides? .

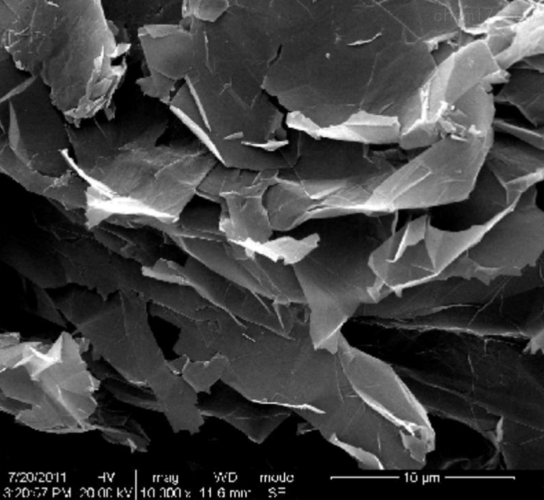

Think of silicides as unique collaborations. Silicon, known for its toughness and love of oxygen, teams up with various metals. The result is a brand-new substance with one-of-a-kind homes. These aren’t just basic mixes. They create distinctive crystal frameworks. Usual silicide partners consist of titanium, chromium, molybdenum, tungsten, and nickel. Each collaboration brings something various to the table. Silicides frequently appear as coverings or layers used onto other products, especially steels. They can also be incorporated straight right into alloys throughout manufacturing. Their crucial function is extraordinary hardness. They resist warmth extremely well. And most importantly, they develop extremely steady bonds with oxygen. This security is essential to their anti-corrosion magic. They imitate a super-strong, invisible shield.

2. Why Are Silicides So Efficient Combating Rust? .

The secret lies in just how silicides interact with their environment, specifically oxygen. When subjected to air or water, the majority of steels react severely. Iron forms weak, half-cracked rust. This rust subjects fresh metal beneath, allowing deterioration continue. Silicides behave in a different way. Instead of developing weak oxides, they create an incredibly thin, exceptionally challenging, and firmly adhered layer of silicon dioxide (SiO2) exactly on their surface. Picture this layer like super-dense, bulletproof glass. It sticks securely to the silicide below. This layer is passive. It doesn’t respond conveniently with water, acids, or salts. It imitates a physical barrier. Hazardous stuff like oxygen, chloride ions, or moisture just can not get through easily to attack the underlying metal. The layer is also self-healing. If scratched, it rapidly reforms when exposed to oxygen, sealing the breach. This mix of obstacle security and self-repair makes them corrosion champions.

3. How Do We Use Silicides for Security? .

Getting silicides onto materials requires smart methods. We don’t just paint them on. One major method is Chemical Vapor Deposition (CVD) . Right here, unique gases containing silicon and the chosen metal react on a hot surface. They deposit a thin, even layer of silicide directly onto the component. Think about it like growing an ideal crystal skin. Another powerful method is pack cementation . The part needing defense is packed inside a powder mix including silicon, the steel powder (like chromium), and an assistant chemical. Whatever is heated in a regulated furnace. Vapors develop and react with the part’s surface area, creating the silicide layer deep within the steel itself. This creates a super-strong bond. Thermal spray is also used for some applications. Silicide powders are melted and sprayed at broadband onto the surface, forming a protective finish. Lastly, silicides can be included directly right into unique alloys throughout the melting procedure, developing corrosion resistance right into the mass product.

4. Where Do Silicide Anti-Corrosion Products Beam? .

Silicides are tipping up in difficult atmospheres. The power field is a huge user. Oil and gas pipelines face harsh inner and external corrosion. Silicide finishings secure essential elements deep underground and undersea. Nuclear power plant, particularly coal-fired and waste-to-energy plants, use them on boiler tubes and warmth exchangers battling hot, corrosive gases and ash. Chemical processing relies greatly on silicides. Activators, valves, and pipelines taking care of aggressive acids, antacid, and solvents require optimal protection. Silicide cellular linings or layers keep these plants running securely. Aerospace and aviation need light-weight, high-performance materials. Silicide layers protect turbine blades and engine parts from extreme warmth and oxidation at high altitudes. Marine applications are excellent. Ship hulls, offshore oil well structures, and desalination plant components frequently fight deep sea. Silicides offer durable defense. Even commercial manufacturing benefits. Furnace parts, metal handling tools, and tools exposed to harsh conditions last much longer with silicide protection.

5. Silicide FAQs: Your Inquiries Addressed .

Are silicide finishings better than paint or galvanizing? Definitely, for extreme problems. Paints chip and degrade. Galvanizing (zinc coating) sacrifices itself over time. Silicide layers are much harder, bond far better, and deal greatly premium protection against high warm and chemicals. They last much longer in severe atmospheres.

Do silicides work against all sorts of rust? They are super stars versus oxidation (rusting) and warm deterioration (like sulfidation in power plants). They are great against several acids and salts. They might be less efficient against specific extremely minimizing acids or severe local deterioration without careful alloy choice and layer design.

Are silicide finishes costly? The preliminary price is typically more than easy paint or galvanizing. Procedures like CVD or pack cementation require specialized devices. Yet the payoff is available in substantially longer equipment life, much less downtime for repairs, and less replacements. For important applications facing rough problems, the total cost in time is frequently much lower.

Can silicides be put on any kind of steel? Mainly, yes. The typical techniques function well on steels (including stainless), nickel alloys, and refractory metals. The procedure criteria (temperature level, gases, time) are thoroughly picked based upon the base metal to make sure a strong bond and the best silicide development.

(Application Of Silicides In Anti-Corrosion Materials)

Are there any kind of drawbacks? The major obstacles are the intricacy and expense of the application processes compared to simpler coatings. Applying very thick finishes can often be complicated. For mass alloys containing silicides, handling may need special melting methods. But the performance benefits generally outweigh these difficulties.